I need to quote 2-4’x8’ signs for a customer and they requested me to use aluminum. I’m not sure what thickness to go with I’ve only used mild steel for my sign so far. I just don’t want the sign to be flimsy. For context it will be mounted on r panel on the front of customers shop. Thanks!

Here is a very large sign cut out of 16 gauge steel by @DnKFab

It will boil down to the supports built into the structure of the sign. If you grabbed a piece of metal and lifted it, you will get a sense of home much it is flexing. Too much flex and that sign is going move/shake in the wind. If it is exposed to the wind and there is not enough relief for the wind, it will have huge forces trying to topple the sign.

If the sign is up against a wall, then 16 gauge would probably work. If you have big holes/openings that will subject all the weight on small bands of the metal then it might distort and bend the sign as you move it around the shop, transport, install. In that case, you might consider something thicker (or build some support structure on the back- bond it with some epoxy or something like JB Weld). Aluminum seems to have less flex than steel but it is a bugger once it gets a bend/kink.

Lots to consider.

I was thinking 1/8” would be sturdy enough but I don’t want it to be over kill.

Look at your design and find the narrowest location. Cut a piece of 1/8" aluminum to that width and see how much flex you get from some moderate force.

Main risk of bending will likely be during handling before you get it mounted.

Did they say why they want aluminum? Seems like a weird preference. Definitely more expensive.

More expensive and harder to clean up after cutting. There’s no knocking the dross off with a wire wheel on aluminum.

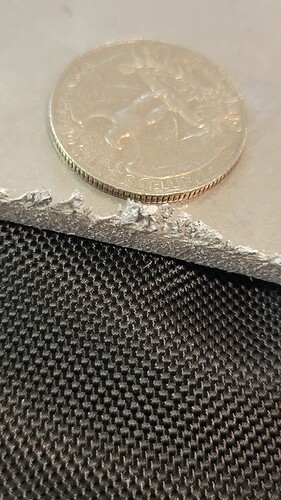

I cut the 3/16 aluminum. It seemed to melt rather than burn. As they said already very difficult to cleanup.

I cut of bit of quarter and 8th-in aluminum.

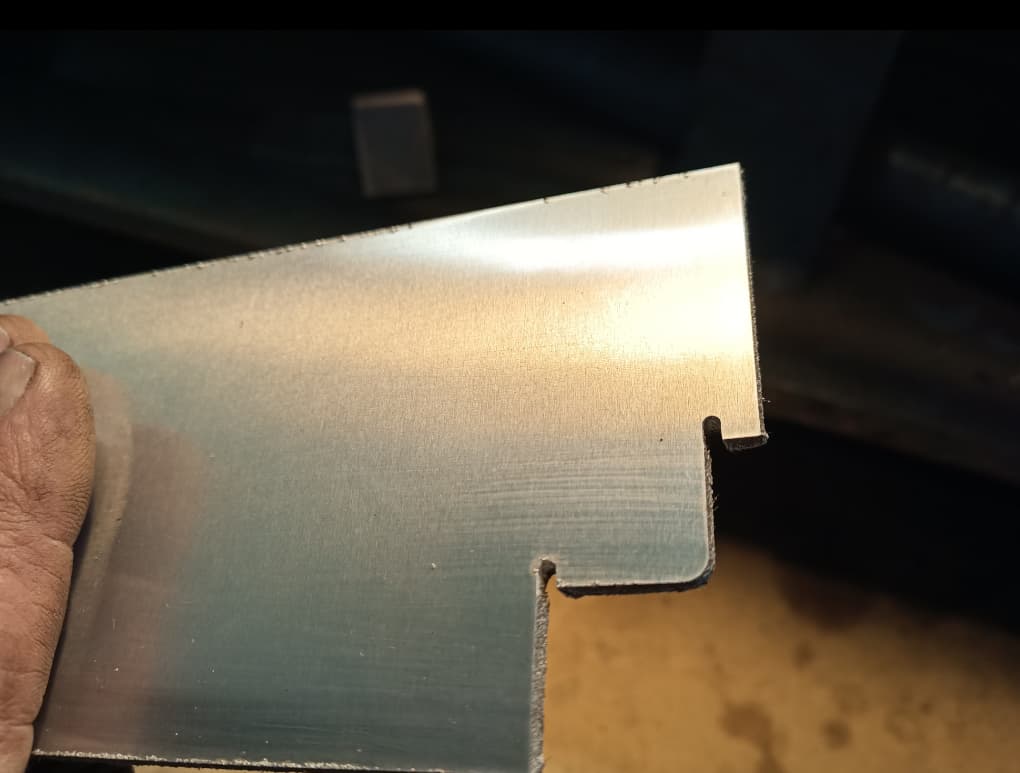

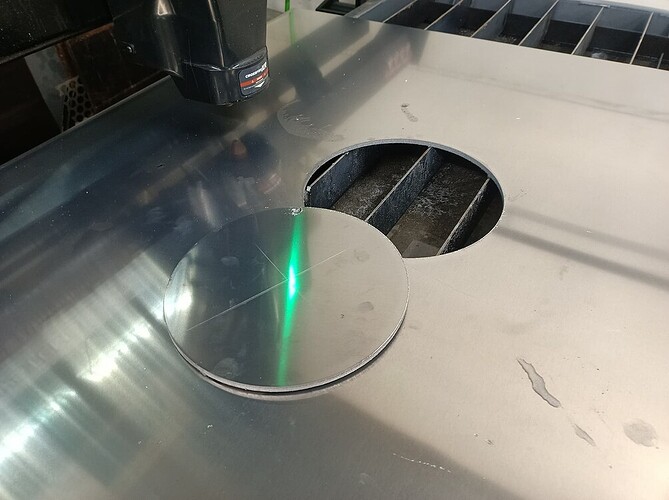

Here’s a recent project of quarter inch aluminum. I used 65 amp shielded book settings from the hypertherm manual.

I end up getting very little dross. The most stress I get on the cut is when you’re cutting a line parallel with one of the slats and very close to it.

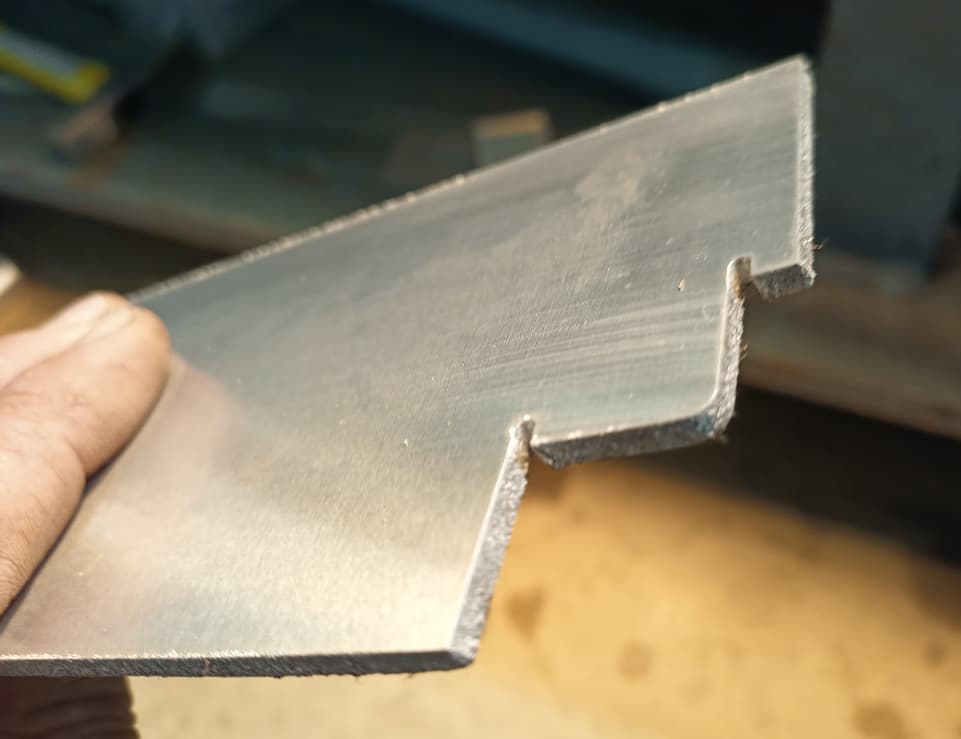

I actually ran an eighth program the other day where every piece came off and I don’t think there is any cleanup before going through the rollers.

For my aluminum cuts I normally use the 65 amp consumables.

These cuts that aren’t even pulled from the table yet basically zero to dross.

Even have decent cuts on diamond plate.

I’ve had decent results with aluminum. I stick with Hypertherm book settings with a 50% turned down for optimization.

Aluminum is the most fickle to cut consistently.

That’s amazing. I’ve cut aluminum twice maybe, I didn’t know it could be done that clean.

^^^^Ditto. PITA for sure. Nice to see that you can get good results.

Best I managed to get was using the fine cut consumables on the thinner stuff, and still had moderate dross, but at least it did not weld itself back together again behind the cut.

Thanks for the input I’m hoping they decide to go with steel it’ll make it easier on me and on there wallet

You might check into what a local powder coat company would charge to finish it and approach it from that angle. Although, you could come up with paint from the auto-body supply company that would be every bit as durable (if not more). The powder coating would take a lot of stress off you, perhaps.

Curious, what alloy / temper do you use Tin?

Edit, do you use various types?