The link I provided requires no electric. When the air pressure drops to a certain point a valve opens and water comes out.

Neither does this:

https://www.amazon.com/dp/B07JGYY78

Sorry to thread necromance here, but an alternative fan on the 'zon that’s a bit more cost effective (1/3rd) and seems to have more CFM than the one in the OP (same current draw, 6.66A, and really good reviews)…

Anyone have any pros/cons of running flex lines instead of Cu rigid ones? I’ve got a tubing bender, but I’ll be the first to admit I’ve never dabbled in pipe soldering (just wire).

Well the biggest drawback and difference between pipe and tubing is that pipe is measured by the inside diameter and tubing is measured from the outside diameter.

so half inch pipe and half inch tubing do not have the same cross-sectional volume.

I did everything in my system in black iron pipe which has all threaded connections.

Those slim line fans are junk compared to the others, will work but will not pull advertised CFM. Im surprised no one has drummed up an AC fan yet. Flex line depending on what kind may not support the temp.

You haven’t seen my setup. Lol. I was going to do a write-up on it one day . But I took a 3-ton American standard trane air conditioner with the splinefin coil and converted it into an air cooler.

Is that a flat or round coil?

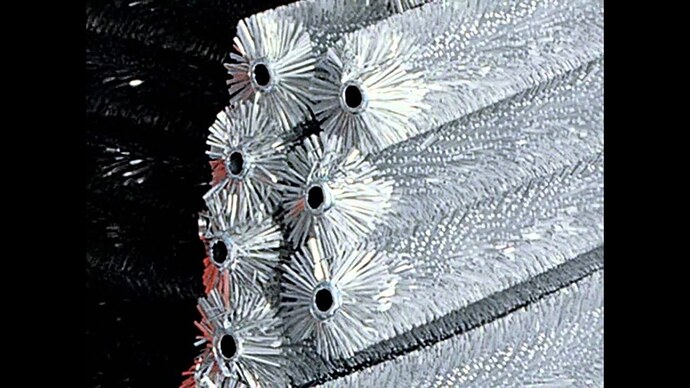

basically a bunch of hollow pipe cleaners

I’ll post a build someday I did take a bunch of pictures when i made the conversion. these pictures above are just off the internet

Was a used coil you had or

Did you buy new? Mount it inside or out?

I was think the same think but I really don’t have room for one inside

Used, it is a older r22 air conditioning model that come from a job . i upgraded the client to a r410a heat pump.

I have it mounted inside up high on the wall so i did not lose floor space. once i removed the compressor it was alot lighter

outside in the winter maybe too cold, at least in my area. If the temperature is below 0c (32f) freeze ups will become an issue.

Good point did not think of that

Well, after two years, I’ve gone through two of the derale brand coolers. My first one I thought had failed due to the use of rigid tubing.

I then had some custom hoses made that seemed to allow some flexibility. But, my second cooler failed last week. Both failed in the same spot, at the outlet into the water separator.

So I went looking for something with more robust connections found the g plus 28 row. Should be here tomorrow. Has anyone else had their cooler fail?

G-PLUS 28 Row AN10-10AN Universal Racing Aluminum Engine Transmission Oil Cooler Black Amazon.com

I have one of those after my tank before my refrigerated air dryer. Almost a year no problem. I do have a different brand larger fittings and such after the compressor.

Sorry to hear about your bad luck.

I am just in the process of setting up this same system: after cooler W/fan plus water separator; and then copper pipe network with gate valve drains. I bought the Derale brand after seeing it mentioned here by others.

Do you think its vibration causing them to fail? Can you upload a picture of the point of failure so I can try to remedy in advance?

I also have a separator just after the tank, and at the table I have another filter and a desiccant bead canister.

@Wsidr1 without seeing a pic of his setup where cracked cant say 100 percent but would be willing to bet 99 percent most likely vibration. Those style coolers need to be isolated from as much vibration as possible and havr flexible lines attached to inlet and outlet so vibrations are reduced to the cooler itself. As lomg as you redu e the vibrations and dont have any weight hanging on the cooler fittings hopefully you will be ok.

Thanks for the feedback. I will try my best to minimize the risk of cracking caused by vibration.

I sure would love to find an off the shelf flex line of some sort to isolate the cooler.

Fkexible lines are available just have to handle the temperature on the inlet side. I would think any good place that makes hydraulic lines could make you some. Big trucks use stainless braided high temp lines for compressor discharge lines and we used to have them made by local line shops.

Yeah my line from the pump to the cooler is Teflon with stainless steel braiding. The point of failure is the cooler outlet. Broken right where the tubing exits the frame. I’ll snap a pic later.

Jegs has a two foot line with 8AN fittings.

350 degree, 1500 psi

Thanks. I ordered them.

With your part#/description I searched Amazon. Funny that Jegs offers a 6AN two-footer for $23 on Amazon (no 8AN), vs $37 (+$15 shipping) for the 8AN on their own website. Adapters are $11.00 ea on Amazon, so even with free shipping, it’s cheaper to get the 8AN from Jegs since 4 adapters would be required.

Thanks again for the tip.