Make sure they’re covered otherwise you’ll get dirty water sprayed all over the place at 150PSI!

I found this out the hard way

Thank you for that information.

That’s a really excellent setup. For guys looking to do copper runs, this may be the design to copy. Those cooling fins are going to significantly increase the heat transfer efficiency.

Probably a wash on total cost and efficiency to a big 50’ long 3/4" all copper run, but less than half the space for the same price is a huge win, plus less pressure loss in the line due to the length of the system.

Well done.

Weird. My HF reefer drains when I let all the pressure out of the line. I must be over thinking this.

How did you wire this to the 220v compressor? Cut the end off and then?

I hooked it straight to the connection that the plug is wired to. So it only kicks on and off with the pump itself.

Can I get a link to those drains? I’m not finding any that look similar. Everything I see is the side pass through.

Thanks, just to make sure when I cut off the plug I then connect the two wires and then the ground same as the 220 side of the limit switch that turns on the compressor. Sorry I’m just a plumber not much of a electrician.

Here you go brownfox

I’ll check mine and let you know. Did you buy the save 240v converter?

Yes, just ordered it today I’ll have it tomorrow

Sorry I forgot to check but yeah that’s what I did.

Just remember that if you tie into one leg of 220V circuit that you’re not going to trip the breaker if you get a short in the 120V adapter. This could cause a fire or electrocution. May also void or limit the $$$ your insurer will pay out if there’s an accident.

Safest way is to wire in the adapter to use both legs of the 220V circuit. (might be what you did… Just wanted to clarify for anyone else that was following along)

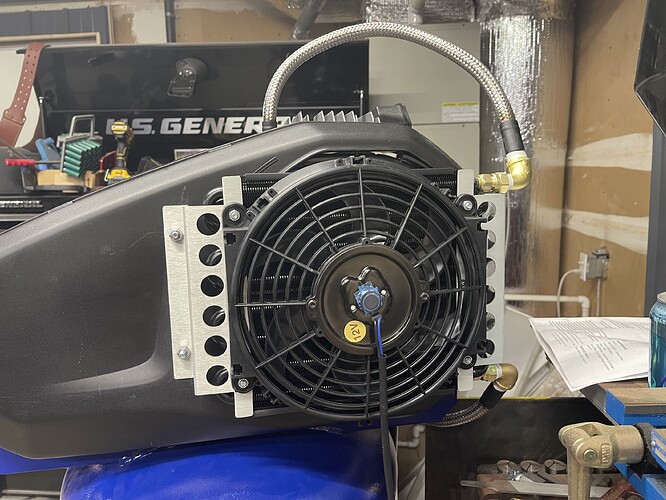

Here’s my solution based off the info on this thread! This isn’t exactly what I had planned, but fittings were difficult to procure, so I did some adaptation. I have not hooked up the fan yet but it already does an amazing job of cooling the air in between the input and output (250+ down to 85 degrees). I’m interested to see what that is once the fan is running!

I chopped off the AN fittings on the after cooler and ran some compression fittings directly on the pipe. I had a heck of a time finding AN to pipe conversions.

Looks clean, great job. I like the braided cable. I swear I tried to have EVCO fab something for me but I was told the only tubing that would handle 300 degrees was cost prohibitive. I have a feeling the guy didn’t really want to help me….

Were you not able to use the AN fittings I posted?

No but I should have used those fittings. I read somewhere that JIC fitting were compatible with AN, but that was not the case. After waiting for my JIC order to show up, which didn’t work, I was so impatient I just cut off the AN fittings and put on compressions fittings directly on the copper pipe of the Aftercooler, since I could get them at Home Depot.

I would recommend just get the fittings the AN fittings that @brownfox suggested for anybody else doing this.