Waiting on a couple more fittings to finish my aftercooler setup but I did notice nobody mentioned that -8an fittings are the same thread and 45 flare as 1/2 flare fittings, so no need to use any automotive adapters on the trans cooler. I just went straight off the trans cooler to 1/2 OD copper line using 1/2 flare nuts, keeps everything looking clean. I’ll post pics when I’m finished plumbing it all up.

Nice! I’ll admit I test fit the the flare nuts right up against the cooler and it looked to be correct… but I chickened out and just used the adaptors since I already had them. It seemed like the swivel feature helped when putting them together, but I don’t think the swivel is necessary. If you get it running and everything is working I’ll update the original post.

The fact that there are 3 names for these fittings makes me want to pound my head on my compressor.

Can you share the information on the dc converter that you used?

Yep, a link to the amazon listing is in the top post.

Here is the one i used.

I searched a bit more and found that 8an fittings say they are 37 degrees, not 45, so technically not the same. They definitely look like they fit when you’re comparing them but I wonder if that 8 degree difference would cause a leak. You’d actually still need one of the 8an fittings I posted above to be able to go straight from the cooler into your 3/8 NPT water separator.

No problems using the 1/2 flare fittings on the -8an ends on the cooler.

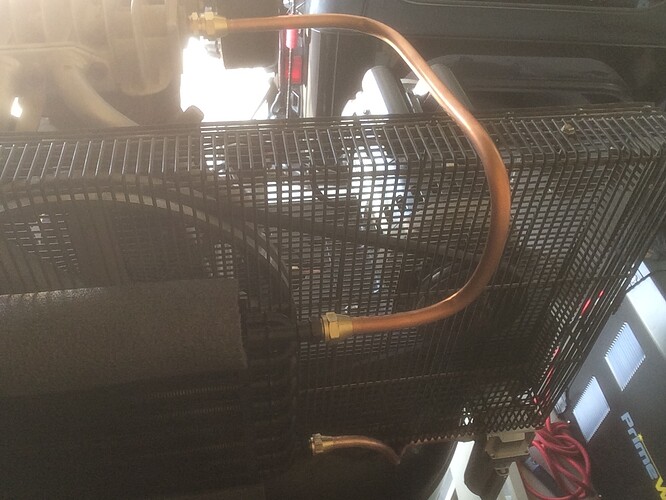

Pics as promised:

Looks good! The foam on the top and bottom helps it look clean. No heat problems with it? I may copy that. Main post updated and credit given to you for the feedback in fittings.

I still need to add my elbows to shorten my tubing runs. I also bought some 8-32 all thread to get rid of the zip ties on my cooler.

But I did add drain hose to my water trap since it purges itself every time and gives a little splash. I’ll post up the parts soon.

Green Locktite once you have it set up!

This thread motivated me to improve air quality while waiting on all of the pro boxes to show up.

Here is what I came up with…

I’m seeing a 200° difference between inlet/outlet without a fan. I plan to add one or a couple small ones once I get my table up and can cut out a shroud.

Can someone explain the science behind having a cooler before the tank?

Cooling super hot air is going to cause condensation and the condensation has to go somewhere, closest place and easiest place for it to drain to is the tank. I’m just confused on how well this works at removing water. As far as cooling air it works fantastic, but it’s water that I’m more worried about.

I’m building a copper manifold now, soldering copper is a pain btw. If this helps and someone can explain to me how this keeps water from forming in the tank I’ll do it too.

My set up is 3/4 ball valve out the tank, 3/4 air line to 3/4 copper tubing in about a 50’ manifold, at the end of the manifold is a rapid air 3/4 air filter/regulator, I then run an airline to my 45xp which has a klutch air filter/regulator, plus the built in 45xp filter. I should be good, but I want to be better. lol

it’s basically a smaller version of a copper manifold with a water trap between the cooler and the tank. water is collected in the trap and is expelled when the pump shuts off. it’s not 100% but I’ve had little to no water in my tank with that setup.

Yeah the key part is the water trap after the cooler. Other wise you’d be dumping the moisture straight to the tank.

I though the same thing when I first heard about the after-cooler idea, then it all made sense seeing the picture with the inline water trap.

I think the real added benefit of the aftercooler is you aren’t getting 300 degree air in your compressor tank. You are dropping the temp 200 degrees and getting water out at the earliest possible stage.

Copper manifolds don’t prevent condensation in the tank right?

Copper manifolds wont prevent condensation in the tank unless it is before the tank with auto drains like our coolers are.

I would be curious to see a copper manifold setup before the tank and see what the inlet / outlet temps are.

I’m extremely happy so far with my cooler pulling 200° before it gets to the tank. Compressor kicked on about 5 times yesterday while I was fooling around with the new table and I didn’t have a drop of water in the tank when I was done.

90 degree air after aftercooler +200 before with my setup. Water seperator after aftercooler with automatic drain.

That’s sideways? Oh thank goodness! I thought I had fallen over and couldn’t get up!!!

go into your files where you keep your pictures on your computer…open one of them up…select rotate 90 CW…that is 90 degrees clockwise…then close the picture…it should rotate it for posting.