Been working on a new caster / leveling foot design using my new Fusion 360 skills. I’m a F360 convert at this point - really enjoying using it now that I know how to get around…and the CAM is great as well. Took some time to get there, but much more proficient now…

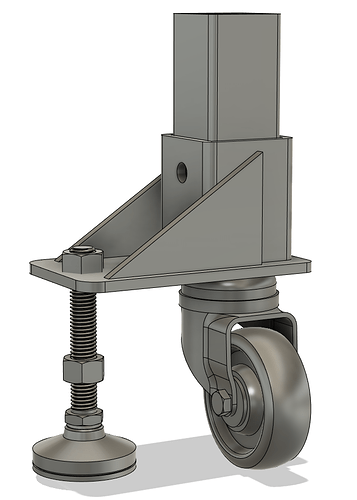

Not sure if this design even makes any sense - I’ve got a few other ideas floating around in my head, but thought I’d put this out there to see if it generates any ideas. 1/4" plate. Tube that CF leg sits in is 2 1/2" .25" wall tubing welded to base plate. Gussets welded to base plate. Tapped for caster and leveling screw.

My goal is to roll it out of storage into working position, put a level on the x and y axis and walk around with my impact driver / socket and level the feet out. When done, I’ll retract the feet and roll it back to storage. Might move to a plate mount caster vs stem as well.