I just started using my machine, I just attempted to cut a piece… and it was supposed to be 25.02", it ended up being just over 24-13/16" tall. The width was dead on. (1" for the main part) any ideas what could be causing this? I didn’t see any binding or anything like that as the job ran. I have the kerf set to .055 in fusion 360, and it looked like it cut on the outside of the line as it was supposed to. this is only my second cut on the machine, and the first things were art pieces where the size wasn’t crucial, so I didn’t even check it.

did you ever get an answer on this, I’m dealing with the same issue right now. however my machine is fairly used.

i didn’t figure anything out for it. the machine has been sitting for a couple years, i just got it cleaned up to take another shot at it. Did you figure out your issue?

Someone broached this a while back. You can download and install another program that will let you calibrate the stepper motors if there is a problem. It is however not for the faint of heart. You can really jack things up, and I don’t know that there is an easy way to unfu@&k it if you missed a step along the way.

This is a feature that Langmuir ( @langmuir-reilly only to get on the radar) should put in Firecontrol instead of having to use an unsupported 3rd party program, or us having to manually adjust the size of a thing to get it to cut properly.

This is a feature that the cheapest 3d printers on the market have had for a loooong time. This is not a cheap import CNC table.

I was doing a search, and the Y axis being off seems to be a thing

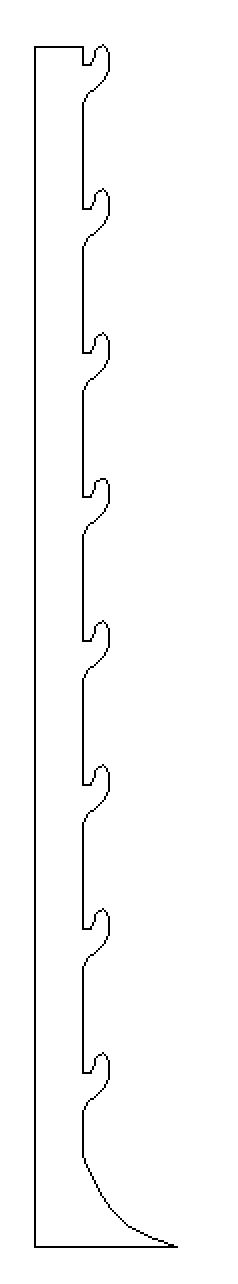

Here is a video on it.