I just spent a bit of time adjusting the bearing block assembly. It seems to me it is better to adjust these before installing the X axis beam. This way as you make each adjustment on the bearing block you can run it up and down the rail and make sure nothing is getting too tight. I was finding as I adjusted the bearing assembly then tightened the Allen heads sometimes is was too tight and dragging so I would loosen the Allen’s and back off the adjuster a 1/8 of a turn and try it again untill it felt smooth.

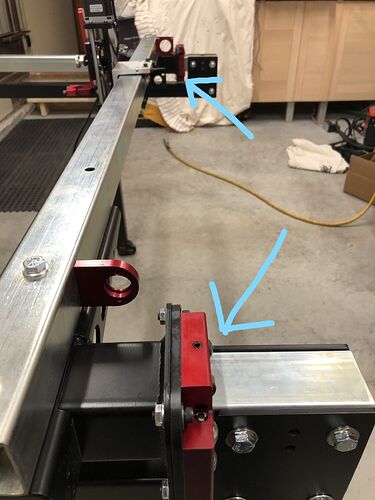

ok…I have attached a couple of Picture of the stage I am at when I started the Step 5 Y-Axis adjustment.

when I slide the gantry all the way to one side against the stanchion plate I noticed a gap difference at the Bearing Block assemblies…is this OK?

or do I have a bigger problem?

Loosen the 6 bolts on the gantry tube and pull it square against the plates, then tighten them again.

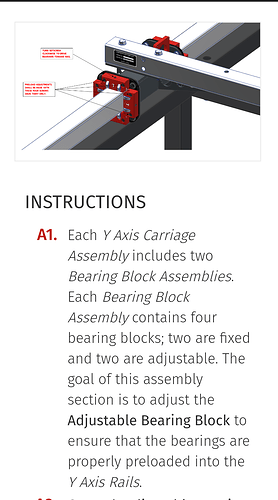

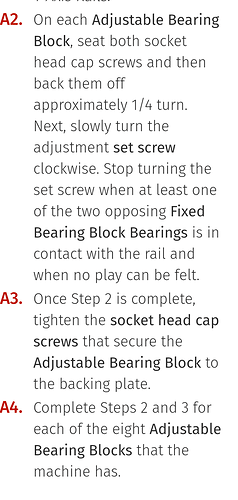

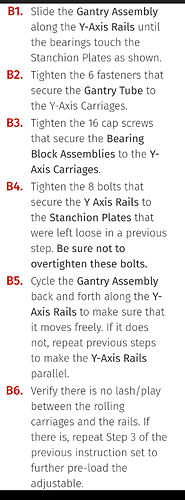

Following the directions here was critical!

When tightening the set screw the direction say turn in only until one side opposing bearing block contacts the rail. Only one needs to make contact then you stop! Why because when you tighten the two cap screws it pulls it in a bit more, if you tended to go to far and you got both bearings on the opposing side touching Then tightened the cap screws, man your really pre loaded now and you feels mucho resistance when sliding it back and forth

thanks toi both of you for your replies.

I actually tried both ways to get it right.

loosened all the bolts going back a few steps

then went back through the steps…but the biggest change was really beingh careful on the block adjustments and then pullingh the gantry up against the stanchion plates when doing the final tighten…now it lines up nicely and slides pretty nice…

thanks

Thanks for the follow-up @toolboy

@toolboy this is a long time since your post but I am at your stage now with my Pro and I spent at least 2 hours out there trying to get this right, trying to make sure that I had the bearings loaded correctly and when I got done every time no matter how careful I was, there is a good amount of resistance. It is not a ton, but it is enough that there is no way it would ever roll by itself without lead screws in there. Is this about where yours felt? Thanks!

Hi Chris,

When i set up a machine I simply make sure that there is no perceptible freeplay or lash in the system. Try not to concern yourself too much with whether or not all bearings are touching the rail. Whats much more important is that the system rolls freely and that there isn’t so much resistance that the stepper motors cant push it.

I’d recommend putting the rest of the machine together and running it, if it needs correction you will know it immediately.

@langmuir-daniel …I have been agonizing over this a bit myself. If there is one other thing I might add after that great suggestion to come back to it, Daniel, in the instructions it says to snug up the cap screws in the 2 adjustable blocks and then in the next couple of lines or says to tighten them using the 4 cap screws to adjust the load. This is where I get confused because it is where I go from nice and smooth to feeling like although it glides, it feels tighter that it was. How do i lock down the blocks without getting to much tension? Sorry for the ramble, I really appreciate everything you guys are doing!

I agree and concur with Daniel…you can leave it till later.

I found even later to back off the adjustment screws…and as long as the bearing assembly does not rattle on the track it works fine.

keep in mind the amount of roller bearings there are…not every one needs to be touching.

Thank you so much for that wisdom.

I think I was being way too OCD about all bearings touching which once I snugged down usually happened, I went back and loosened up the set screws by probably 1/8 of a turn and then retightened all blocks and the 8 holding them to the tube. It definitely rides easier and now if I kind of push it, it continues to ride just a bit after.

Today I get the water tables and will continue on this adventure! Wish me luck! Haha

I had it going for a couple days, then my bearings tightened up I saw a few ideas on the thread like oiling the lead screws and adjusting the bearings a little. I am now 100% confident it needs to be rebuilt / fixed.

How would you recommend I go about repairing / re-adjusting my y axis bearing blocks?

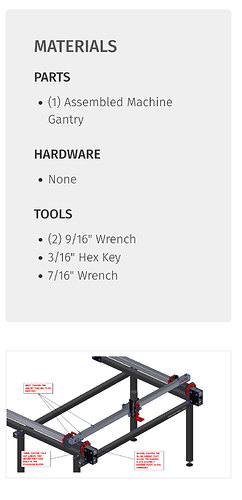

Here is a few screenshots from the assembly manual for the crossfire pro.

I had a little bit of a tight spot on mine and I started adjusting from the tight spot.

Think I should de-assemble my lead screws then? I’m trying to follow Langmuir Daniels forum post to fix this issue without taking it apart but one set of top bearings stay tight no matter what I do it seems.

If the Gantry is all bound up the lead screw is not doing you any good anyways. get it out of the way so you can solve the actual issue at hand.

True say, thanks mate.