I did what you recommended and loosened the rod end bearing and bearing mount while it was at the home position and had it line up naturally with the rod and tightened everything back up

Awesome. Does it home now without binding?

No sir it still bound up a few inches past home, I cut the same file for the 22”x12” 3/16” plate tonight with the kerf set at .050 with a 45 amp cartridge and it was a 1/4” out of square diagonally.

I redrew the part in F360, saved as DXF to my computer, uploaded in Sheetcam, went from flash drive to the Langmuir computer, cut another plate and was closer to 3/16” off diagonally from corner to corner.

I have no idea what else to do, I am seriously considering selling this machine since I can’t get it to do what it’s supposed to do.

Sam, don’t give up. We learned that the binding is not the relationship between the rails and the screws. Im pretty sure your rails are out of adjustment right at the end. This would also explain why you had to again remove paint and use an abrasive right at the end. My suspicion now is the aluminum bracketry at the end of your table that holds the end of your rails and your screw mounts.

Where they mount on the the body of the table there is some play there. If you tightened all the bolts in the wrong order you could have caused that long bracket to act a a lever and either pushed the rail out or pulled it in. I would move the gantry to the middle of the table and loosen one of those brackets and allow the rail to relax. You could put some reference marks on the body and bracket to see if they move when you loosen the bolts.

When you tighten them down again. Make sure it is not causing any deflection in the rail. The lock ring on the rail should be tightened last.

As far as the square issue goes, there is no solution to that other than partially disassembling your machine and squaring it.

I drew your 22x12 panel out of square by just under 1/4" and it shows in the drawing that its off by 0.7 deg. Which makes your table out of square by 1/2" or so assuming the two long sides are parallel.

I just have a hard time seeing many people have similar issues like I do (binding and such) keeping these machines around. I did a lot of research and looked thoroughly through this forum before I made my purchase, I tend to look more at negative things than positive, in some situations positive reviews are paid for.

But now that you say the tube mount bracket, I remember when I did the opposite end of home position on both sides when I loosened those 3 bolts it moved quite a bit and with tightening I noticed it would move as well, I think I will go back and look at this this week depending on snowfall……

If I’m out a 1/2”, which I believe can/is maybe possible, could I remove the entire waterbed along with the screws and the slats? Leave everything else together? Biggest problem I see is obviously a leak after reinstall and the holes not lining back up to original ones……

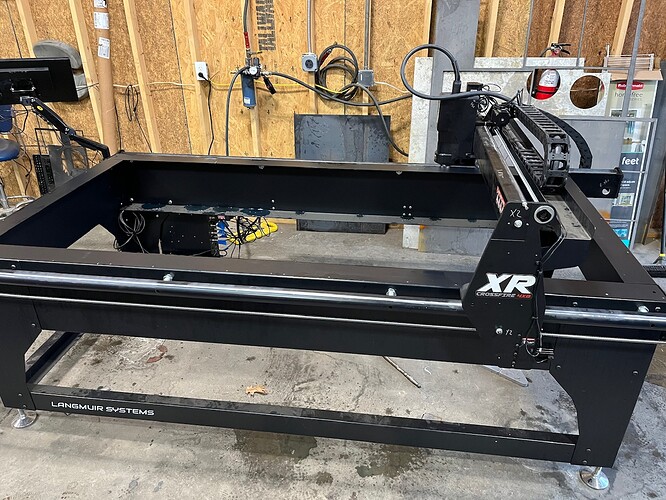

I understand your frustration as i have been in your shoes. My first purchase was a crossfire pro. I had no CNC experience. I totally walked into the unknown. My learning curve was more like i was standing at the bottom of a 1500ft cliff with no climbing gear. There was about a 3 week period where i had lot of anxiety over having wasted 4k on what was a paper weight to me because i couldn’t figure it out. After i learned how to run my machine i then had binding issues, plasma issues and any other issue you can conceive. My process was painful. That pain is behind me now, i have upgraded to the XR and the table is now a tool that i cannot live without. You were not misled by your research, you simply underestimated the learning curve as I originally did.

Any effort to shortcut this process will cause you issues later. I would disassemble the water table completely and clean off all the sealant. When you reassemble later i would get new screws with the sealing washer and go through the whole water pan assembly as per langmuir instructions once you have squared the table. Im sure you can use the same screw holes in the base along one side but the opposite side will be new holes in the base. No big deal.

Once the table is square and water pan reinstalled, i would then check your rails again for square and parallel. I would consider removing your screws all together and loosening the bottom side Roller and just manually rolling the gantry along the rails. It should be perfectly smooth rolling the entire length. You could even use some chalk dust to see that you have even connection between the rollers and the rail. If you only see one line in the chalk then adjust the rails accordingly. After perfect adjustment tighten up your bottom Roller. Remember this is just tight enough to stop any play and absolutely no tighter. After that. Reinstall your screws, align the screw mounts at each end with the gantry and you should be back in business.

Other than hand held plasma torches this is my first CNC plasma machine as well, and yes this most likely was a little above my head but I wanted the challenge of building one of these kits, at the time I didn’t think it was going to be this difficult to have everything aligned properly.

That is one heck of an explanation, cheers to you for that!!! I will start this process soon, I want to try to check for square with a folding ruler underneath the machine first before taking things apart, just for my sanity at the moment. Plus it’ll give me a reason to go to the hardware store ![]()

![]()

Ammon thank you and the other members here for the help!!!

it just occurred to me that you could use a laser measuring device. I have wanted to buy one. they are supposed to be super accurate these days and I can’t think of an easier way to measure that under the table.

Wow!!! I have a Bosch one in my toolbox……. That didn’t even occur to me to think about even using one. Just was thinking of doing it the old school way, I’ll try this tonight and see what my reading is. Thank you again!!

So my Bosch laser wasn’t a viable option, I was not able to get a good accurate ready from under the table because of the tubing brackets that are on the inside of the corners.

I started to drain some of the coolant tonight, I feel this is the only reasonable solution at the moment.

I do want to post some pictures after looking over the machine again as Ammon mentioned.

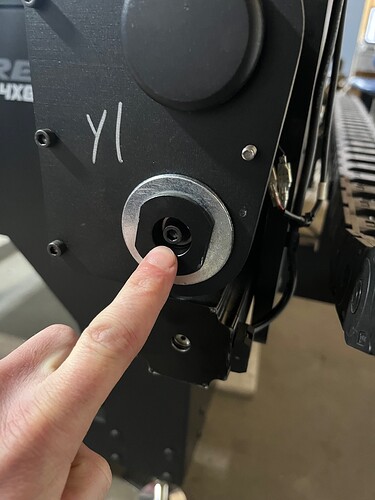

I noticed that both of the tube mounts were not equal, not sure if this is part of the problem or not.

2nd set of pics is the opposite end with computer

I just want to say you have gone above and beyond helping here. My hats off to you well done!

Wasnt that long ago i sat in my garage on the verge of tears staring at the wall. because i genuinely thought i would never figure it out. Made me sick to my stomach thinking i had just convinced my wife to let me spend 4k (all that we had) of our savings on this new tool to promote a better fab business only to have wasted it.

Turns out i had underestimated the value of a plasma table to my business but i have this forum to thank to get me going and saving me from despair ![]() . Just returning the favor.

. Just returning the favor.

I have a potential idea for checking squareness… what if you were to wrap string very tightly around the entire perimeter of the legs just below the upper rails and then use the “3x4x5” measurement were you would use a sharpie and mark 3’ from the corner leg onto the string on the width of the frame and 4’ mark on the long part of the frame and string, then measure the distance from dot to dot of the marks and it should be 5’. Hope that makes sense and if not I could mock it up on my machine and take a picture to show you.

That’s actually a really smart idea but I was looking at my table and the side panels drop down so far that what you are actually checking is the average squareness between the top and bottom of the frame. It might reveal a problem but I don’t think it would be very conclusive.

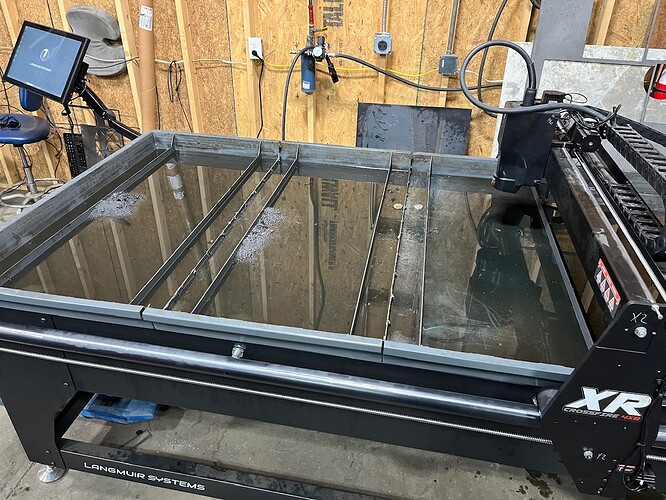

Finally got around to taking the bed apart

After taking all the screws out, 1 at the computer end got stuck as if the frame sprung some, after pulling the entire bed off in 1 piece, I took a measurement, and this is what I I came up with……

As I stated before I was 1/32 or so within the measurement, it seems it was still there. But I can rack the frame now with the bed off, I’m thinking of clamping some bars across and see if it will hold the measurements this time.

What do you guys think?

Do you think it got out of square when you installed the water pan?

I can’t remember all the info in this post, but I would try and get your problem taken care of before reinstalling the water pan.

Are you talking about clamping bars to hold it square while checking it with the water pans off? If so I think that will work as long as it’s stiff enough to hold things from racking

Man I have no idea, I was thinking that with the weight of the water in the bed it may have moved stuff around but I really don’t know.

What I want to do is clamp bars across to keep everything tight then reinstall the bed but I’m checking some other things before I put that back on.

I took the ball screw bearings off the drive motors and the gantry rolls a good distance before it stops also I scrapped all the paint off where the rollers touch the tube to make it smooth , other than the inner line on the bottom side of tube, I can’t really get that one.

I checked checked squareness at least 5 times last night and clamped 4 pieces of square tubing and the bottom of the top channel of frame and 2 pieces of 3/8” flat bar in a “X” on the lowest frame rail, I am currently 1/32” out of square for over a 9 foot span. I am realigning the Y tubes getting the 1.25” measurements going the opposite side and using the DIM A measurement adding the 1.75” and am within 1/32” of that measurement as well after that I retightened the tube braces on each end, next up is reinstalling the bed, starting at one corner then going across to opposite corner then so on and so forth the rest of the length. After this we will readjust the rod bearings and mounts.

We got the bed back on and is much more square than it was I ended up using #12 screws this time, I reinstalled the bearings and tensioned the rods, moved the gantry back and forth at different speeds and finally 400 ipm. Ran the break in program twice and at this current time there was no binding, here is a video.