I read the official literature and checked the forums but didn’t find this particular topic.

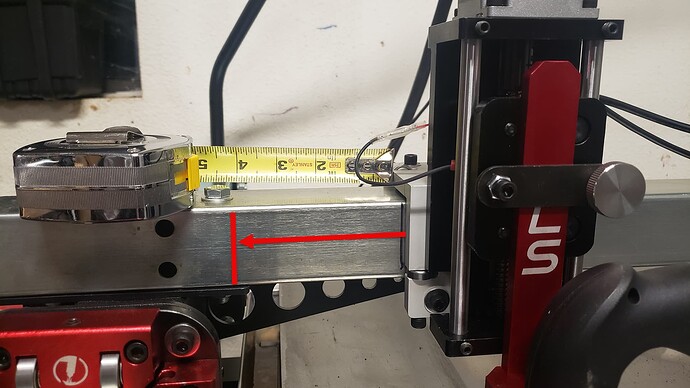

If I go by the official cut dimensions, the area of travel in the X-axis is supposed to be 48".

When manually jogging using FireControl, my X axis only travels 44".

It hard stops on the right side at the end of the table where expected, but hardstops exactly 4" short on the left.

I inspected the area closely and don’t see anything obvious it could be running into. The area is free and clear. It doesn’t slow or grind down to a halt, it makes the same same sound as the right side like it hits a stop. Otherwise, that 44" of travel is smooth with no issues at any speed.

Any ideas of what it could be?

Thank you!

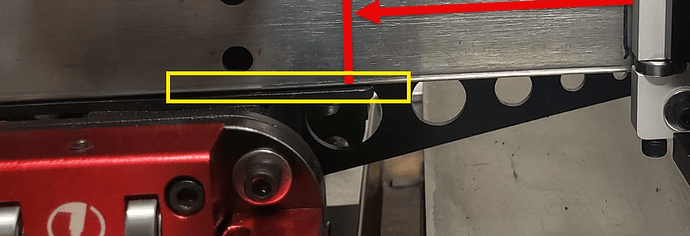

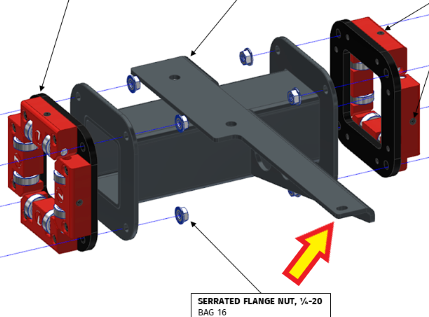

Either you have the wrong Red bracket on that motor or the little black bracket on the back of the z-axis carriage is cockeyed.

3 Likes

The red bracket is the correct bracket, and the little black bracket on the back of the Z-axis is free and clear. The lead screw works fine and doesn’t wobble or shimmy like I’ve seen other people report. I can still cut what I need to cut with no issues. I’m just short 4" on the left.

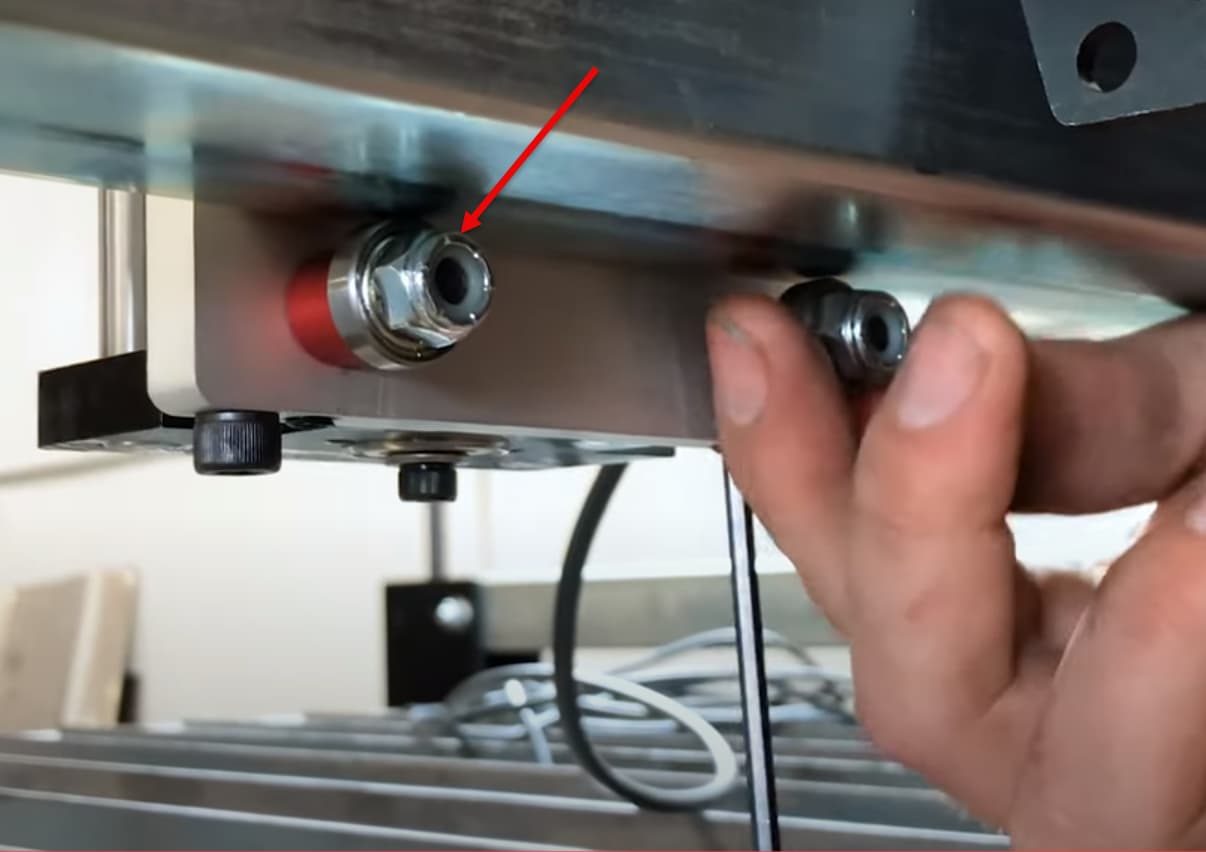

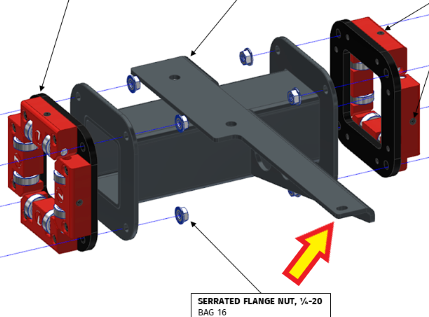

It does appear that there is a bit more bracket showing on the torch side of the bracket: Is there the same amount of the bracket showing when looking down from the top?

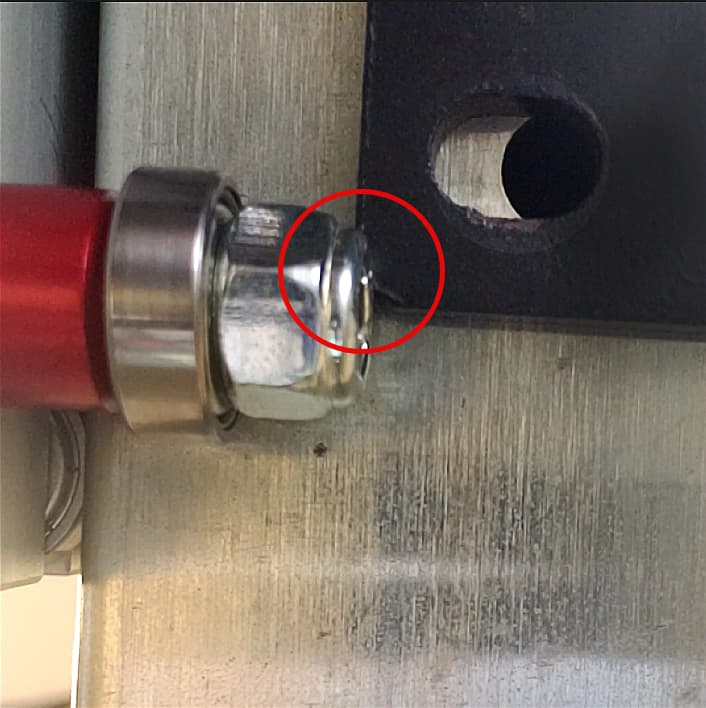

If it is tweaked just a bit, it is possible to impinge on this part of the carriage bracket:

As you can see, that bracket is specifically cut out to allow for the gantry/z-axis assembly to dock on that left side.

This is how mine looks from the top view. It appears about 1/16" consistently showing:

5 Likes

Thank you, Jim.

I’ll check to see if I misaligned that bracket somehow and follow up.

1 Like

Hello Jim.

Although the bottom of the X-axis Carriage Assembly is difficult to see when operating, I was able to finally see that the first guide bearing would clear the corner of that extended bracket, but the second guide bearing would hit the corner of that bracket exactly where you indicated with your red and yellow arrow. It was only impinging by a millimeter, but that was enough to stop travel as if it had hit a hard stop, which technically, I guess it did. I tapped the bracket until the second guide bearing cleared that corner, and tightened the nut holding the bracket in place.

Thank you very much for taking the time to point me in the right direction!

I appreciate it!

5 Likes

I will accept the thanks for @TinWhisperer. He spotted it: keen eyes on those bots!

1 Like

All the credit to you @ChelanJim . I was talking about the smaller black lead screw bracket at the back of the z carriage

3 Likes

Thank you, TinWhisperer.

All input has been very helpful and appreciated. Doesn’t hurt to ensure the newbie triple-checked the different components to rule out the potential cascade of contributing failures. Sometimes it’s the smallest thing that gets you up and running. As we’ve proven, even a millimeter can make a difference.

3 Likes

That is so nice for you to take the time to thank us.

The way you will pay us back is to learn your system and teach us some stuff… Well, me anyway.

2 Likes