Hello,

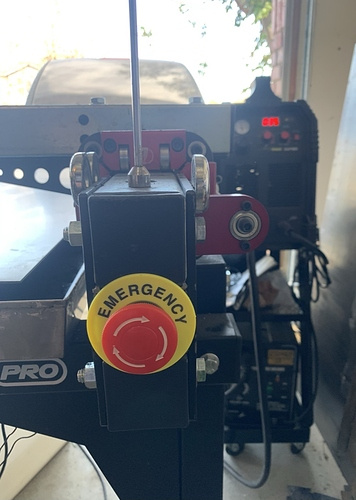

I am hoping someone smarter than I can help. I would like to know where on the Crossfire Pro control board I would wire in an ESTOP button. I already reached out to Langmuir but they said they are reluctant to share that information and suggested I ask the forum.

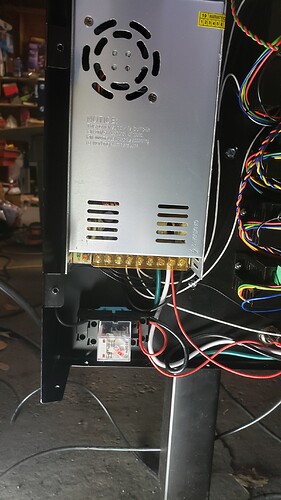

Your best bet for an E stop is to wire it to the 36v DC power wires that power the drivers and the torch fire relay. If you cut power there all motion will stop and the torch will shut off.

Hello Daniel,

Does Firecontrol stop motion if the plasma lose voltage or arc when running off the material?

It won’t stop itself until the arc stops. My hypertherm will run off the table pretty far when I screw something up. As long as the work clamp and the arc are connected it will keep running.

I added an e-stop to mine… well technically not a true e-stop but more of a torch cut off button. I have a magnetic torch holder so if the torch hits a tip up and separates from the holder, I can hit the button to turn the torch off. already had to use it a few times.

It also works well if you need to do a dry run with the torch off so you don’t have to have the cutter off or disconnect the torch on/off cable from the control box.

I’m interested too. I’ve been looking at e-stop options for my CNC router and will want one on the CFPro too. As I learned from my router, it will attempt to go beyond it’s table if I mess something up, and essentially “crash”. That, coupled with tip-ups and other problems, make an e-stop vital to protect my machinery and materials.

The struggle I’ve found is finding a way to e-stop without the machine needing to reboot and therefore losing it’s place on where it was last cutting (on my router). Annoying as if it’s a 2-hour run I am faced with starting over and watching it try to cut the same material for a long time before it gets back to producing parts.

I haven’t spent a ton of time on it yet, and the software is different between my router and Langmuir, so I’m interested in seeing what others are doing with their CFs.

what your looking for is limit switches… the pro control board has pin outs to add limit switches in the future but langmuir hasn’t put out info on that yet… Until they add it to firecontrol, there’s no way to use the pins.

The way I wired the “e-stop”, if I have to turn the torch off during a cut or tip up, I can always “run from here” somewhere close to where it left off.

As far as going off the table, you’ll just have to make sure your project doesn’t exceed the limits of the table. i don’t see how limit switches would work if your project is bigger than the table and you hit a limit switch, your project is already messed up because it can’t cut beyond that point anyways.

@langmuir-daniel I found this website and was wondering if this is the same wiring that would work on the Langmuir Control Box or do you have any other suggestions? I’ve already purchased 2 E-stop buttons and would like to get them installed.

http://www.hobbycncaustralia.com/Instructions/iI17wireestop.htm

Thanks in advance!!!

I have large amount of experience building automation for theater, people movers and machines to move scenery. An e-stop was mandatory on everything. Osha required that the e-stop interrupted the power to the machine. I have found that the easiest way to do this is to use a switch that interruptes the power from the mains. Usually I would use a normally open relay connected to an e-stop switch. In this low wattage application I would think you could find a switch that would be rated for the load and the relay negated. This switch could be placed in line with the power cord.

Interrupting the power to the computer box should also cause the torch fire relay to disengage causing the torch to stop firing.

I added an e-stop to my pro today. I used a 120v relay wired to the e-stop switch. I interrupted the hot wire between the switch and the power supply. I used an aviation connector in the back of the control box so the e-stop can be disconnected.

like the low voltage idea…but could you not just be real basic…and put a light switch in line with your power cord to the box… and use that as a “lazy cheap-ass” way of installing a stop switch?

I know I can get the fancy Red/Yellow big button…for emergency stop…but for fast cheapo way of doing it seems like it will work the same…

It would absolutely work the same. My original plan was to put the switch in the cord, I never made it to home depot to get an electrical box for the cord.

I’ve got one of these for the control box.

But I haven’t tried it with the plasma firing so can’t verify your thought that if you kill the power to the control box that it will also kill the arc signal & the plasma arc.

I got mine from Amazon but it was $5 more but I got priority free shipping so I went there for it.

I can confirm that when the power is cut the torch stops.

i don’t see the logic of killing ALL the power instead of just the torch. If you shut everything off then you lose your zero’s . At least when you only kill the torch then you can start from last loop.

That’s what i did with mine. just wired it inline with one of the torch on /off wires inside the control box to interrupt the torch firing.

That is what I did…I have long welding rated power cord that runs from my table to plug in the wall…then I have a SPDT switch installed on that cord at the table…then there is a pub-in for my plasma on the table…

so at any time I see the plasma going crazy…I throw the swutch and just the plasma dies…PC keeps running…

so you cut power to the cutter itself? I just wired it like if i had unplugged the torch on/off cable from the control box. no need for thick wiring.

I agree with you. This is the better way to wire it. But one question…when torch stops does everything else stop?

it’s hit and miss… sometimes i get the lost arc error so i can start from the last loop and sometimes it’ll keep going as a “dry run” until i stop the program in firecontrol. Then i would have to manually go to the last loop and run it from there.