I have three of them. They all perform well. As soon as you get it, you can tell it’s not a piece of junk.

I purchased an MR1 a couple months ago and for some reason expected is to be assembled ![]()

![]()

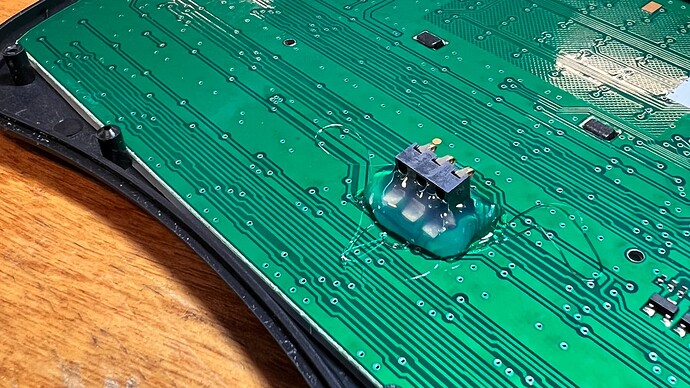

anyhow first jogs around setting the limit stops the pendant failed and found this thread.

Re-soldered the failed joints and it works again.

I would just add that u might want to add hotmelt glue around the battery contact part to reinforce it. Ideally before you put the battery in. I’ve done quite a lot of cad work on electronics enclosures and pcb and plastics and it is absolutely totally not ethical to use solder joints as a structural element in the assembly. The force from the battery contact springs pops the module off of the board. There should have been a little plastic rib or something in the enclosure to support the plastic pcb component.

I have 3 also. They work great.

Same issue, mine had very little solder and what was there was cold jointed. Embarrassing, even for China.

I have three of them. They all perform well. As soon as you get it, you can tell it’s not a piece of junk.

Agree with you. These are much better. Its a shame for the few extra $$$ that Langmuir doesn’t upgrade from the garb they have now

Tbh, they realized they screwed up the spindle nut threads in an epic way and they chose to continue with the non-standard part configuration despite having industry standard identification markings on their collet nuts. This company isn’t big enough to eat the costs of a screw-up like that. They likely purchased pallets of those pendants and they’re going to use’em up before they go with a better option. Hopefully they do just that when the time comes.

Just the way it is sometimes if you chose to go with a budget machine. With what they put out at the cost they do it, its still a hell of a deal and if a shitty pendant soldier joint and some slow to non-existent software development is the trade off. I’m still happy. I’m also not afraid or unable to fix things or make my own modifications if I’m not happy with what I got. I wouldn’t dream of that with a Haas or even a Fadal.

That wasnt a screw up that just demonstrates the terrible engineering in the rest of the machine.

I just struggle to agree with this. I have beat my head against the wall trying to figure some of this stuff out.

Just to show how crappy this machine is I came in the shop a few weeks ago and noticed the control box laying on the ground. I had not used the machine in several days and it fell off because of the cheap rubber mounts they put on them kinda like everything else.

Some of you guys are extremely talented and have no issues installing new drivers and controllers etc but not everyone has that talent. I was sold a machine that I knew probably would not hold a tight .002-.005" tolerance but this thing is barely able to turn the spindle on. Had I known I would have to put all this time and money into it I would have thought hard about other avenues.

10th grade kids could have designed a better programming system.

My stupidity is I also bought the XR at the same time. It isn’t as bad as the MR but I have still had way to many issues.

So I have $13K in these machines and still dumping money into them.

What really stinks is there service is as bad as the machine! The guys are nice if they will answer the phone or call you back but that is probably because they are on the phone from 8-5 with so many problems.

I will never tell anyone this machine is worth buying but if someone likes stuff like this and is OK dumping more time and money into it then this is definite the machine to get.

I completely disagree that its a good deal. This is my entire point. Giving people that garbage pendant out with your new machine when you could spend just a few extra $$$ and get something much better and that is the same with the those .50 cent limit switches that are extremely important to precision. It just shows the lack of care they offer.

Sorry for the rant.

I can’t disagree with your points, they most certainly are valid. And to be honest I can’t say I’m exactly surprised the issues some are having have cropped up. What can you expect from a group of guys that make plasma tables? Its very much akin to asking a welder to do precision machine work.

It sucks they can’t be more responsive to your issues but from what I’ve seen in most cases, they’re honoring their warranty, which is all anyone can ask for.

Everyone I know that dropped the cash to get the next best thing, a Tormach. They’ve all had somewhat similar experiences with their machines. Sure they’ve been in the machining business a lot longer but they still decided to go “custom” instead of industry standard. I think they’re just now starting to offer BT spindles in their “Industry grade” machines. Their control runs on a PC and they kluged an R8 collet system into one that’s ATC capable and I can’t recall what they call the “system”. Its got its issues.

Quite frankly, if you’re looking for an industrial level machine with great customer support, able to hold normal machining tolerances (less than .0005"), a control that recognizes the most basic G and M code commands, uses industry standard tooling, doesn’t run on a PC, and doesn’t require assembly. You need to get yourself a nice used machine or get yourself into a new one from a name brand instead of from some welders who developed a fancy CNC router you get to put together yourself using concrete, a few pieces of square tubing, and an aluminum work table all driven by stepper motors.

If you have the knowledge expertise and ability, be it through setup, tuning, adjusting, shimming, or outright modifying, the MR-1 can be capable of holding sub .001" tolerances. But its not going to be that way out of the box, and certainly not for <$10K.

That being said I absolutely disagree with the decision they made to use the spindles they had made with the incorrect threads. I don’t know how many units they had made and I don’t know what their backend looked like at the time but it would have been the right thing to do to scrap the spindle shafts and had them remade, correctly. The other thing they did I absolutely disagree with is they left all the markings on their nuts indicating they were standard nuts, which they clearly aren’t. It bugs me so much that I’m going to make a new one myself with the industry standard threads and fix what they should have. But I also have the tooling and materials to do it, all it will cost me is time. I most certainly understand not everyone has that capability. I also understand that I can’t rely on Langmuir to fix my machine for me. For what I paid, they did their part. If I have a warranty issue all I expect is that they honor what they offer, as long as its covered. A loose solder joint on the pendant took me all of 10 min to fix while I was waiting for something else to finish. I consider the MR-1 the HFT CNC in my garage. Its a hell of a lot better than what Amazon had for sale ![]()

After our rants (LOL) If there’s anything I can do to help with your machine, let me know I’d be happy to help you get your machine working as intended. Outside of any warranty issues of course.

Just about any company big or small will make bad decisions with a new product. It is the chance we take has an early adopter of a new product. Some of use see the MR-1 has the most expensive piece of equipment we have bought and compare it in are minds has a Mac to a dell pc. When the related is we bought the dell and not the Mac. For me I know and went in believe that the MR-1 would have issue being it a new product, and especially a type of product for which the company had never offered. I already had a crossfire pro so was well aware of how communication and update to issue would take time. They are a small company which result in staff wearing multiple hat. If you want to see that even one of the big Cnc companies in the industry still fails at the same level with a new machine offering just go check out the YouTube Chanel of Tom Bailey racing https://youtu.be/dVVNbSOHVvI?si=JCRAEs4iFyjUdpqP

He bought one of the most expensive Hass mill which at the time was a brand new machine. It took well over a year before they even got one part made of the machine.

I am going to try and get this thread cleaned up so it stays useful and current for new users.

Customers opinion and experiences with a product is extremely useful and current, especially for new users.

Sure the specific topic of went a little off the rails but thats the nature of discussion. I’d even argue the discussion here is the lack of quality control with this specific component of their system.

Any good product, if you’re bringing in 3rd party components or assemblies should be subjected to a QC process just like parts manufactured in house and not just rely on the vendor.

Even if the thing costs <$20. Customers shouldn’t have to pay to get something that requires replacement as soon as it come out of the box.

Send it back. They will send you a new one. They are not all defective. Maybe 1 in 20. I realize its a pain in the butt. I’m sure they will upgrade when the 500 they own are gone. I personally have two of the original ones. Though I don’t like it feel or operation, they both still work.

the title of the thread is wireless pendant fix, if you want to complain about the pendant ok but anything else add no value to this thread.

Can you please explain why the Rii keyboard is better than the Langmuir stock one? $25 is cheap enough to try, but I’m just a little fuzzy on what the advantage is.

My Langmuir mini kb works fine… usually. It does go into sleep mode quickly and requires an extra button press to re-connect. And it feels like a cheap / flimsy piece of crap.

The Rii one looks identical, like it popped out of exactly the same mold, so I’m struggling to believe the build quality is different on the housing or the buttons (although I understand the solder quality is better).

Also… has anyone found a way to step the feedrate preset up or down from the mini keyboard?

That’s the biggest thing I’m annoyed with. Always reaching around the door to touch the screen when I’m jogging around.

Agree to disagree.

At present the only way to change feed is with a mouse click. I’m not aware of any keybindings, unfortunately. I’m in the same boat as you, keyboard shortcuts would be a nice feature.

Dont get too far off topic though, some people might complain ![]()

There is no advantage. Its just better quality. The feel and buttons have a good feel. It works the same.