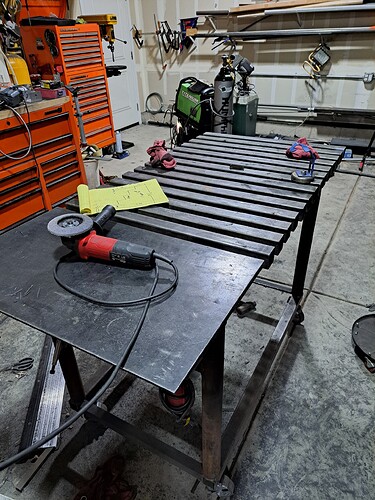

well i came here to stir the pot and get some ideas. I have lost sleep over this topic. i have been living off a very small home made welding table and it’s way past time to upgrade.

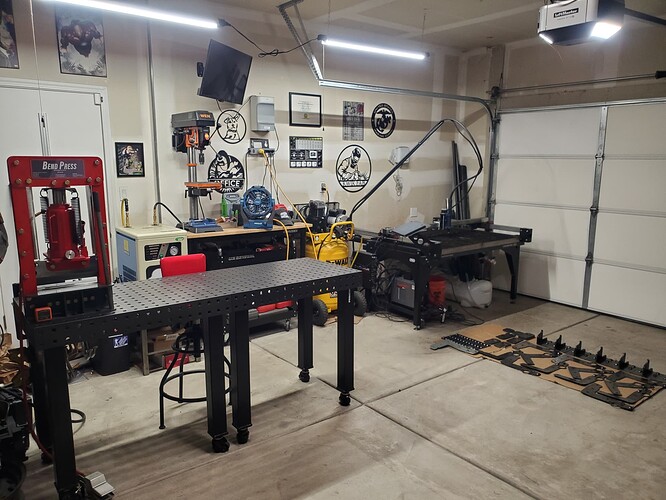

I have tossed around building my own table with some features i think would make a very versatile and useful table. i know langmuir has the arc flat table which in the category is by far the most reasonable and fireball just seems obscene.

this is where i will spark some debate. when it comes to fixture tables, I’m not convinced. what am i missing? People talk about fixture tables like the verdict is in and i can’t have a seat at the table without one.

My current design allows me to clamp anywhere on the table my clamps can be used on and off the table unlike fixture table clamps. My materials list for a heavy duty 48x96 welding table will be about 500 bucks. An arc flat table which is by far the most reasonable for a quality table will cost me north of 4k for the same size table. a fixture table is meant for clamping and squaring and reliably flat. i am 100% confident i can achieve all those things with a carefully crafted home made welding table and a few good squares and save around 4 grand.

will my table be as flat as an arc flat? no, but you’d have to get out the machinist tools to tell.

Am i missing something? is it hype? is there some sales pitch that can convince me that i need to spend the 4 grand?

2nd question:

what features can you not live without or are at least worth considering on your welding table? Just looking for good ideas I haven’t considered yet if i build.

I’m either buying or building very very soon and i want this to be the last table i buy or build.