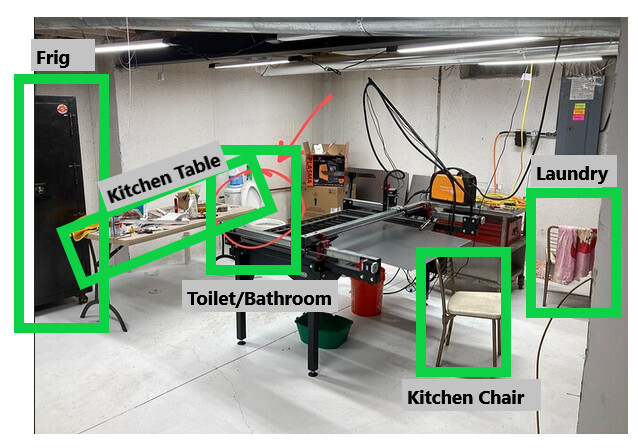

Good catch BigDaddy! I am beginning to think this is RunsWithScissors’ entire home:

Old @RunsWithScissors has this thing figured out.

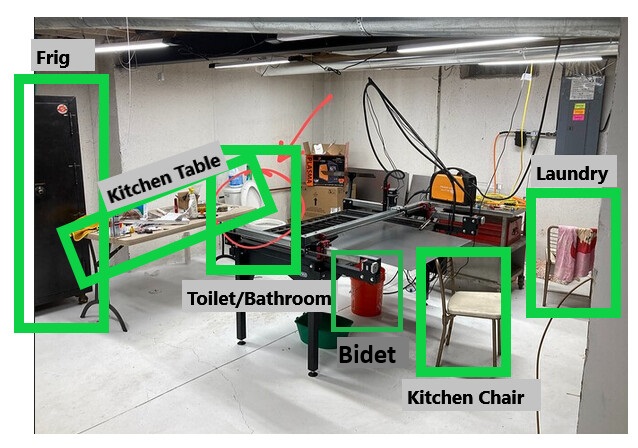

Clearly you missed one

@Kwikfab …That bidet… OUCH!! ![]()

![]()

![]()

![]()

![]()

First of all I love your setup… I am very envious of your basement and your collection of tools!

BUT… I have to ask. Do you share your place with a significant other?

I could never get away with any of that. I once got in trouble for putting some of my stuff on empty shelves that were too high for the little women to see what was on them. She told me she wanted those shelves empty… I replied they are shelves… they are supposed to have stuff on them… and you can’t even see what’s up there!!

Not long after that I saw some cookies on top of the fridge and thought she must have left them there for me… I grabbed one and sat down with a glass of milk to enjoy my cookie. I had just taken my first bite when she came in the door and saw me with the cookie in hand and scolded me for eating the cookies she had hidden for later. She then asked me how I found them. I walked her over to the fridge with me… they were hidden on top of the fridge which just happens to be right at eye level. ![]()

![]()

![]()

Yeah no welding table cool kids club or anything. I used a 3x6 piece of 1/2 inch for a long time. It worked ok but tacking things to it never sat well with me, I wanted things as smooth as possible. But it was definitely not flat. And some of my projects showed it, or at least I’d like to think that was the case and I often found myself wanting to clamp in the middle.

Since getting the arc flats there have been several times that I’ve clamped in the middle and it’s definitely sped things up. The few things I’ve made do seem a little easier get flat, maybe I’m just more patient these days, but my old piece was definitely not flat. If you’re got a decently flat piece and it works, save the money.

I will agree with @Bigdaddy2166 the holes are a pain in the ass for anything except clamping and welding. I had to buy a sheet of plywood to put on top because it’s so often a secondary workbench.

I don’t know… ![]() Having sparks landing in your lap while you’re doing that?

Having sparks landing in your lap while you’re doing that? ![]()

Just wrapping up my weld table build using 9 arcflats. I designed the frame/structure to allow each of the ‘nodes’ to be leveled using the leveling pads underneath.

Using diagonal stretched piano wire with one of the wires offset up by the diameter of the wire, i made the four corners coplanar by making adjustments to the four leveling feet at the floor. Then i stretched piano wire across top surface over the top of the ‘nodes’ and adjusted the leveling pads underneath to make the table exceptionally flat. The entire 6’x9’ surface is flat within about .010".

Still need to inject epoxy into the liquid shim bolts and then torque the nuts. Then i can remove all the tie plates from the top of the table that are there to eliminate steps from table to table.

The last step will be to move it into final position, redo the diagonal piano wire adjustments to essentially untwist the table (as it will have twisted to conform to whatever shape the concrete is in), use my machinist level to make the table earth level, and finally drop the remaining 8 leveling pads (not shown) lightly to the floor just to stabilize it, hopefully without imparting a flatness error.

I’ll be using this table for custom tube chassis builds and couldn’t be happier with how it turned out.

Daniel, that is superb.

Just an observation: You have room for that large fixture table because you don’t have a toilet, bidet, frig and kitchen table to fit in there. Someone earlier in this thread could learn something from you!

He also doesn’t have to go far to put limit switches where you think they belong.

this started out as a thread to discuss welding tables and evolved into showing off our shops (which i support).

but then i see a guy with a toilet so convenient he doesn’t even have to take his boots off to use it and another guy with a half acre of arc flat and im starting to think the Rockefellers are highjacking this thread.

I’m not mad about it. if you can put away the jealousy, it can be encouraging to see people living out their dream. It keeps the dream alive that i could one day have a porcelain office chair in my garage.

also, if you put some threaded feet on that kitchen chair, you could probably get it calibrated and it would be a good as any high dollar machinist chair.

table is coming along great. should have a finished product this weekend

hahaha, you guys are funny!!!

Mrs. RunWithScissors is pretty understanding. I think she see’s my “tool habit” as better than a “bar habit”

When I built the house, I had plans to turn the garage into a workshop and “finish off” the basement.

But then “life happened” , plans changed, and now my garage has this thing in it, so no room for my shop.

So “the shop” got moved to the basement, and after the first 2 lathes, Chi-Com mill, and welding table got down there, well I spend lots of time down there…

With me being the “laziest man south of the Mackinac bridge” got tired of walking up the stairs to piss.

Then I remembered that I had the basement plumbed for a bathroom in anticipation of it being used as living quarters…

Hence the toilet…

Funny how life evolves aint it?

You should have been there, when Mrs. RWS came home and saw the garage ceiling laying on the floor in anticipation of the newly arriving hoist…Now that was quite a dinner conversation…hahahhah ![]()

![]()

We have a tool box in the garage with several empty drawers my wife hid the cookies there. I think you’re wife needs to be a little more crafty when it come to hiding stuff. Would she like my wifes #? ![]()

![]()

got the new table done. put in some long hours today so i could get back to my paying jobs. had more Monster beverages than the usual and the frequent trips to the john made me realize that the basement shop toilet now lives rent free in my head.

anyways, here it is.

used trailer hitch tubing for the frame just so i could attach tools at all the corners as needed. never had such a versatile work station.

also wanted to mention the Evolution saw is new. never even tried a carbide saw before this weekend. Cutting with that saw is such a pleasure, the first cut i had a private little cry in the garage it made me so happy.

Looks great. Well thought out too. ![]()

What happened to Daniel’s Photos?

He must have decided to take them down. God knows he has the ability to control the forum page. It was a nice setup, though.

That’s awesome. Looks really good.

What mag drill is that? I’ve been wanting to get an evolution one for a while. I have one of their saws, yeah they are great for sure.

I can still see them, maybe a glitch some were.

Sir, the struggle is real but the only question you need to answer is how accurate and repeatable your work needs to be. If you don’t need repeatable accuracy, don’t spend the money. Those tables are for fixturing parts to make them more accurate and allow for faster production. If that isn’t where you are you need not worry about it. I make fire pits and signs so I have no need to fixture my work. It is always one off jobs unless someone orders a fire pit from me and those are simple enough to do without a fixture table. I just made a set of spacers and use those to keep the fire pits accurate enough for what they are.

I hope this helps you in some way. If you really feel the need for a fancier table start small and see how that goes.