Cable layout makes a big difference. If the USB and the work clamp (yeah its a technicality but it’s not really a ground clamp) were near each other it was guaranteed interference for me. It would only cause firecontrol to freeze (in 2020), not quite what you’re describing, but if it’s working now, that may have been it. Keep it going!

yep, so far, so good.

Working on loading and cutting more plates this morning. Highly inspired now that i see how well it works. Just wish Fusion wasn’t so technical.

I was looking at the ArcDroid prior to finding the table that I have. Thought the ArcDroid to be second rate compared to the Langmuir/Fusion 360 combination but then found that Fusion was needed with the ArcDroid too if I were to get the best, most accurate performance out of it.

I am counting on improving my grasp of Fusion, I’ll get there someday.

I spent the money, I’m too cheap to quit.

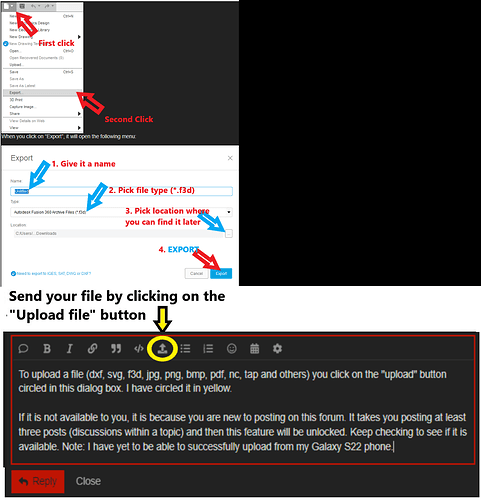

Lots of help here for Fusion. Also great videos on YouTube. Remember, if you are posting here and specifically have questions for Fusion, pick that category under “Software.” At least 20 different people regularly respond to help. To get the quickest and most efficient help, share your f3d file. It is a file made specifically by Fusion 360 and has all of the settings so that we can see what you are seeing.

Note: The only time it changes things from your computer to ours is when you use a specific font: if our computer does not have that font, it will load our default font.

Here is one of several ways to create and upload an f3d file:

Thought I should check in and let you all know how I am doing.

I have setup a couple more projects and it seems to be working fine. Really fun to see it make such clean accurate cuts. I will be cutting some suspension parts for my AC Cobra replicar tomorrow.

I intend to relax with it a little bit and learn about nesting parts to make the best use of my metal, I have wasted some metal while getting accustomed with it.

I want to cut a 36 inch tall Snow Gauge, wondering how that will work on a 24 inch table?? We usually get more than 24 inches of snow here in Minnesota.

I know. It is almost magical… Like Santa! ![]()

Search the term " index cutting"

This is the method you’ll need to do if you’re cutting designs that are bigger than your table.

I will have a look at it.

Thank you

@MnRoads welcome to the forum!

Congrats on getting up and running and working through the issues.

Very jealous!! Building/owning an AC Cobra is a dream of mine! I had a chance to buy one 80% complete a few years back. I am still kicking myself that I didn’t pull the trigger.

I almost had my wife on board… then her dream home lot came available, and we are building a house. Back to saving my pennies.

What kit are you building? What engine are you putting in it? Post some pics of your build so I can live out my dream vicariously through you!

Sounds like you need to give the boss another Spa Day with her girl friends, just in time for Christmas. I can’t really remember how you talked her into the 3D printer. I know it was tax return funds but some other magical twist.

I thought about doing something similar. My thought was to make it in two pieces and bolt together. A little easier to store although a 36" snow gauge wouldn’t be that hard to store.

Mine is a Classic Roadster, they have 7 inches more leg room and the seats are mounted 4 or 5 inches lower on the floor pan than the Factory Five or other kit cars. I am over 6 feet tall and was lucky to find this car, my head is above the windshield, knees up into the dash, getting into and out of the Factory Five sized car was not going to work for me. The Classic Roadster fits me much better.

It has a Ford SVT 4.6 litre Teksid aluminum block, 4 valve aluminum heads, DOHC, naturally aspirated ,fuel injected engine hooked to a Tremec 5 spd and 3.50:1 rear gears.

On the dyno it put out 349 hp at the flywheel.

I bought this car nearly complete, lots of wiring to clean up, some handling issues, and recently installed electric power steering with coil over adjustable ride shocks and springs in the front end. It is a fun car to drive with the exhaust right outside the door and open to the air. I really enjoy it.

The little picture, avatar?, next to my name is a 34 Ford 5 window coupe that I have owned since I was 15 years old, had a 392 hemi in it, still own it today.

I have a few other cars that I am fairly proud of, too bad I had to wait until so late in life to be able to enjoy them, or afford them.

Very nice car, Thanks for sharing!

I thought about repurposing an old cutting edge from a skid loader bucket. Worn down it would have a rounded face rather than sharp edges, enough straight steel to cut and use for the base so it sits on the ground rather than sticking it in the ground and getting it to stand up straight.

Love it!!

I was right out of college and still single at the time. My boss told me if I was going to do it, I needed to do it then… He said otherwise I would be old when I got around to it and everyone would wonder what the old guy was doing in the nice car… Turns out he was right.

At least you were able to get it… I am still hoping… but I am not going to hold my breath.

That used to be the case few years ago but it’s been a while you can save all the tools in the cloud too along with the designs

Is anybody on here today?

I have been away for about a week and must have done something wrong. The X/Y Z axis are mixed up. The only time the are oriented correctly is if the cube says TOP. The result is that when I load my sketch it is not with the gridlines.

What have I done wrong?

I did a video once about index cutting but I’m having problems finding it.

I’ll see if I can get down to the computer and do something.

In the meanwhile search “work coordinate system” or “WCS” you’ll need to learn about this to perform an index cut.

This is a good write-up about index cutting

WCS is in Setup in the Fabrication dropdown under Cutting. I hope that is the answer, but the question is how did I change that setting? Doesn’t it stay from one project to the next?

I will get right into it now and report back.

Thanks

I have it set on “Model Orientation” what is it supposed to be on?

No matter which choice it does not change. The top view shows the correct x-y axis with the gridlines to layout my project, the front view shows the plane as a flat horizontal line with y pointing up and x pointing right.