The issue that users will eventually run into with the new style X45 torch (which is a Chinese copy of an Italian copy of a Hypertherm (designed and built in the USA) torch) is that the design operating load voltage of the Razorweld power supply is not high enough. The Hypertherm consumable design requires a much higher arc voltage than the original torch that is shipped with the Razorweld. The RW power supply can achieve the higher necessary arc voltages that are necessary with the Hypertherm consumables, but must work harder to do so. Cutting power is the Amperage x Arc Voltage = Wattage. Higher wattage output of the power supply that will naturally occur will exceed the design duty cycle rating of the RW power supply, and ultimately will cause some field failures. Arc voltage is the voltage measured between the torch electrode (negative) and the workpiece (positive), and is controlled by the resistance of the plasma arc and the length of the arc. You will be fine if you stay on very thin materials, but as thicknesses increase the arc is longer, the arc voltage is therefore higher. The Hypertherm Powermax systems and torches are designed in house by the same engineering teams, so are designed to handle the necessary arc voltages at their advertised cutting duty cycles for many years of plasma cutting use. I think the X45 torch is a good idea for improving the performance on the RW system, however I would be concerned about premature power supply failures. The alternative is to spend the money and buy the US designed, engineered and manufactured Powermax. Costs a little more to purchase, costs less to use (best consumable life). Cost of ownership is lower. Jim Colt

@mechanic416 That’s definitely the style torch that I have, and it’s the one shown in the manual for the machine on their website. Check out page 15 in the link below:

The advantage I see with the new torch style is using a consumable that is more readily available and not having to unmount the torch from the machine every time I need to change nozzles. Additionaly, the longer cylindrical section on this torch should give a much more reliable place to clamp on to compoared to the tiny ledge of the cup on the S45 style nozzle that came with my torch. I find it very tricky to get the torch perpendicular to the workpiece with that setup.

That being said, if the price to get the new torch is $399 like @charry8 said, I can’t see getting this torch instead of a CNC torch that is actually intended for this kind of use.

What I was really hoping for was a little help from @langmuir-daniel identifying if we could buy just the new torch head and new nozzles to retrofit our existing torches without having to buy a whole new torch assembly. Any chance that will happen?

The red torch you posted a picture is a trafimet S45 style torch. The torch on page 15 of the manual I have never seen on a RW 45.

I sell a high quality made in Italy CNC torch for $360.

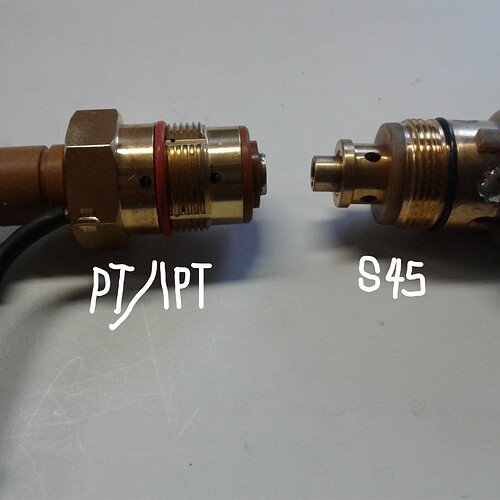

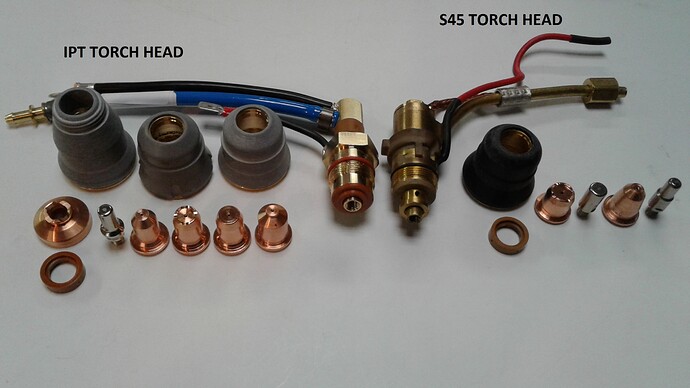

Check your torch and see what torch head you have IPT or S45

First picture is the RW 45 torch, second picture is a IPT and a S45 torch head.

I think people should know what they got, not what they think the have.

I bought my RW45 a year ago when they were introduced at that great price, and started out using the consumables they sell with the machine. After reading mechanic’s stuff and seeing the pictures, I decided to try the IPT consumables, and it made quite a big difference to the performance of the cutter. The quality is better, but more importantly the consumables seem to last forever. It might be that I’m getting the Italian Tecmo ones George sells, or it might be the IPTs… Either way I don’t think I’d ever go back as long as I own the Cut45.

“I sell a high quality made in Italy CNC torch for $360.”

HOW DID I MISS THIS? That could be a game-changer for us RW/Everlast/Primeweld users. Is this something you’ve always sold because I don’t think I remembered it last time I bought consumables.

Here are some pictures of the torch that came with my RW45 and the S45 compatible consumables I’ve been using with it. I just got done cutting some pieces from 1/4 mild steel plate, and I’m actually more pleased than usual with the results! That being said, I had the same issue getting the torch perpendicular to the plate as normal. That’s definitely a finicky issue that I would love to find a way around.

Using S45 copy drag consumables on a IPT torch on a CNC table, not bad. Just think of what you could do with the right consumables for it.

It’s really weird that they sell the Razorwelds with an IPT torch but S45 consumables and then pitch the same consumables. Not only are clearly (look at mechanic’s pics!) putting S45 consumables on an IPT torch, but I think IPT consumables are preferred if you could take your pick of torches because they offer shielded versions. (Someone correct me if I’m wrong about S45 not being shielded).

We’ve had a lot of complaints here about the Razorweld, and I’d be willing to bet a lot of the issues could be resolved by using the right consumables. To me it’s akin spending all this money on a new turbocharged sports car and then all-weather tires on it. It’ll run, and if you aren’t used to the car you’ll think it runs well, but…

I urge those with the RW torch above to give the IPT consumables a try.

The big issue with consumables is people are buying the cheapest ones they can off amazon or Ebay and they just don’t work. While they may look the same or similar there is still a big difference in quality.

Buying from someone like myself or George or a RW reseller or someone with known good quality consumables are the best route

With all due respect, the Razorweld branded consumables are S45, which is the issue I have. I don’t care if they are high-quality Italian S45 tips, they weren’t meant for the torch that’s included with the Razorweld, and there are no brands out there with that torch that use or recommend S45 consumables.

It’s completely confusing to customers, and that along with the lack of a cut chart or duty-cycle@amps specs just seems like irresponsible business to me. They have what looks to be a great power supply, but they are lacking in the easy stuff imo.

I still love mine and have just ordered a Tecmo machine torch for it, I just get perturbed when I see the product bad-mouthed when it has more to do with the lack-of and wrong information they are giving with the product.

/rant

S45 is more well known than IPT60. At one time the s45 is what the RW came with.

The IPT60 and S45 can interchange the consumables (have to swap them all, can’t use s45 electrode with ipt60 tip etc) and in fact you will find that a few manufactures will do this. IPT60 torches can obviously handle higher amperage and probably a better fit then spending money on a s65 torch. It’s not just RW that does this.

Everyone complaining about a cut chart needs to understand that this is a plasma cutter. It wasn’t designed specifically for CNC use. Hence why it never came with a CNC connector. So in makes no sense to make a cut chart for hang cutting. Again a lot of companies do this. Find a machine with a cnc port and there are good chances it comes with a cut chart.

I have to agree with Gamble here a cut chart is just a starting point only. The same cut setting you have will not work well with someone else even if they have the same plasma cutter and table.

All this will depend on air pressure, consumables, torch height, amperage, ipm setting, etc, etc, etc.

You can set 2 units up exactly the same but use different swirl rings and they won’t cut the same.

Case in point, here are 5 swirl rings they will all fit the same torch. but only one was spec-ted by to torch manufacture.

The one on the left is a Trafimet for a S45 the air holes are bigger then all the rest. Then Tecmo IPT, then the next 3 are copys. They all have different size air holes and are all drilled at a different angle. I have seen some with the holes drilled straight in, some with only 3 holes, 2 holes and made from wow knows what. There are a lot more , this is all I had laying around. So make sure you are using the right swirl ring for your torch, it may be the only reason your having cutting trouble.

Do you happen to know of pin outs will work on an everlast 60s or if they’ll even work at all?

Mine does… it has a CNC board built in.

I am a little confused , do you want to change your 60 amp torch for a 45 amp torch?

I’m confused as well. The real question I have is why anyone would want to buy a new hand torch when they can get a machine torch and have the best of both worlds?

Guess the amperage rating didn’t cross my mind. I guess what I’m trying to ask is, is it possible to use tweak a hypertherm machine torch to work on the everlast?

Well, yes you can adapt a Hypertherm machine torch to a Everlast 60S. But whats wrong with a PTM 60 machine torch. You get a better selection of consumables with the 60 over a Hypertherm.

Rxmart2, you saying you have the S45 Torch? (I do, that’s what my cutter came with). But your using the IPT consumables on it and your getting better cut results?