Brand new guy here. I’m attempting to assist a fellow veteran and 07FFL in setting up an MR-1 to machine the Fire Control Group pocket on AR15 and AR308 80% serialized billet lower receivers. I have the program in .tap format but CutControl does not recognize it. I’m probably missing something basic. I was going to attach the program to this post but I can’t because I’m a new user. Any guidance would be much appreciated. Thank you!!

Little more information would help? What software do you use for CAM? If fusion did you setup the post process from Langmuir for the MR-1?

I downloaded the program directly from a firearms CNC website. I do have Fusion 360 free version and I downloaded the MR-1 post for it from Langmuir’s website. Thanks for the reply and, again, I am a total noobie at this stuff.

Based on your statement about the .tap file, I suspect you have a G-code file. However, unless that G-code was created specifically for the MR-1, it usually won’t work. (With some time, and understanding, you “could” re-write the G-code to be accepted.)

What you would normally want is the model. (3D solid or Fusion .f3d) Something that can be loaded into Fusion. Create the tool operations needed, then post process with the CutControl processor. Then the finished G-code can be loaded into CutControl.

Open the .tap file with notepad. Is it normal Gcode or something else? I suspect its not g code.

I opened it with Notepad. It is definitely G Code. I suspect that it is not in the correct format for CutControl to read.

POCKET.TAP (27.7 KB)

I just received permission to upload so here it is. Thanks everyone!

Confirmed. I’m not sure what it was posted for, but here’s the differences in the header…

.TAP file

(0001)

(POCKET)

(T1 D=0.375 CR=0. - ZMIN=-1.39 - FLAT END MILL)

G90 G94 G40 G49 G17

G20

G90

A .NC file posted for MR-1

(v1.6-af)

(MR1 Test)

(T1 D=3 CR=0 - ZMIN=-0.0215 - face mill)

G90 G94

G17

G20

G28 G91 Z0

G90

Note - This is just the header. There are probably a number of other issues with the .TAP file. Can you get or have access to the original model?

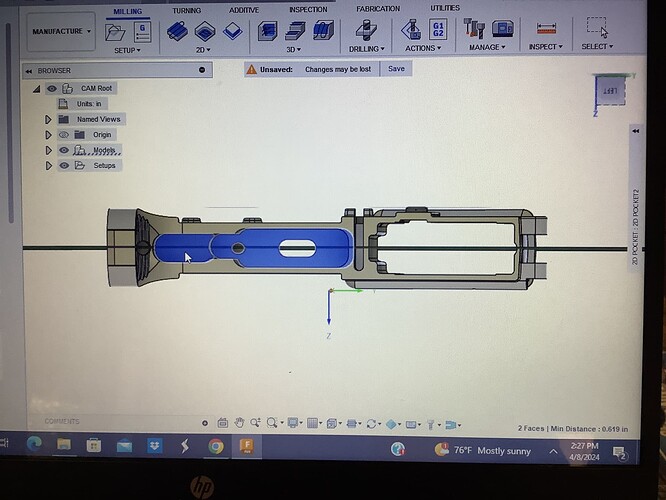

Here is a 3D model. I can’t get it to do anything but open in Fusion. I also attached a pic of the only 2 pockets that need to be milled out. The XYZ is wrong in the pic. Thank you for your help and patience.

AR15_Lower_Receiver.IGS (4.1 MB)

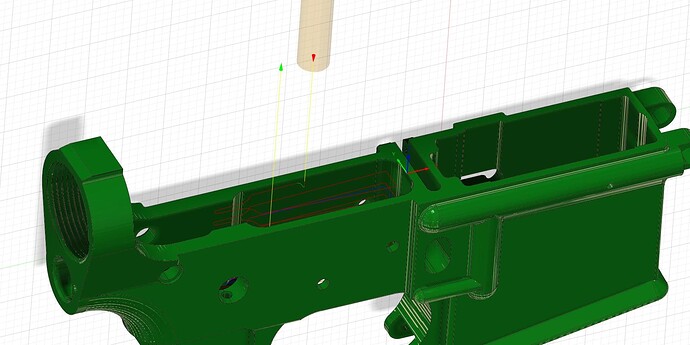

When you say “Can’t get it to do anything…” what have you tried? I was able to open the .IGS file and save as a Fusion project. If I were taking on the machining, I’d then move to the Manufacture tab, establish a Setup with an origin point (based on how you intend to hold the work.) Set Z0 to the top of the receiver (or another point you can easily touch off). Then it’s not too hard. 2D Contour with multiple depths, choose an appropriate tool, ramp for lead in, leave (Stock to Leave) .005" on sides and floor. Run a 2nd 2D Contour with similar settings leaving 0.000" on the sides and floor. (I’d change to a finishing tool personally.)

Note - I don’t have or normally program for an MR-1. I do regularly use Fusion to generate G-code for a HAAS VF3SS. (The process is very similar!) You may get better answers from one of the MR-1 owners around here.

Edit - Something like this …