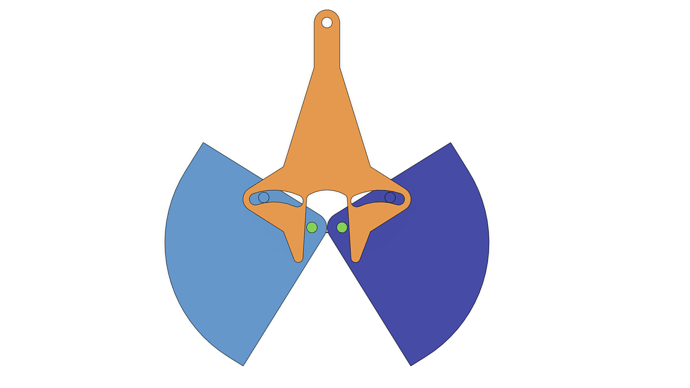

Today I want to do a video about a interesting project from @knick, a clam shell bucket repair piece.

The interesting part of this project is the slotted arc that guides the motion of the bucket.

It this video I want to;

-sketch the geometry using provide pictures and measurements of the project.

-Create the components of the working pieces from the sketch

-Use joints to prove the motion of the pin to the slotted arc.

I am trying to get started by 9am pst today.

here is the file from the video

clam shell bucket joint study v1.f3d (175.6 KB)