Hello,

I have a new Crossfire XL with powered Z - Axis. I don’t understand what initiates the THC function in my cut files. Is running the post processor for Firecontrol what determines that THC will be used? Or is there something else I need to do? Also, as I’m preparing to cut my first job (I been working on Inkscape and Sheetcam) I assume that Firecontrol will sense where my Torch height is upon startup and then THC takes it from there. Any help would be greatly appreciated. Thanks!

you have it mostly right…

so the z axis is known as THC…Torch Height Control…

You will need to purchase sheetcam to make any use of it…the free version will do a box and not much more.

you will need to install the post processor from Langmuir into Sheetcam in order to use it…

then once you do a drawing and have a DFX or SVG file…you open it in sheetcam and create G-code from there and put that into firecontrol to cut.

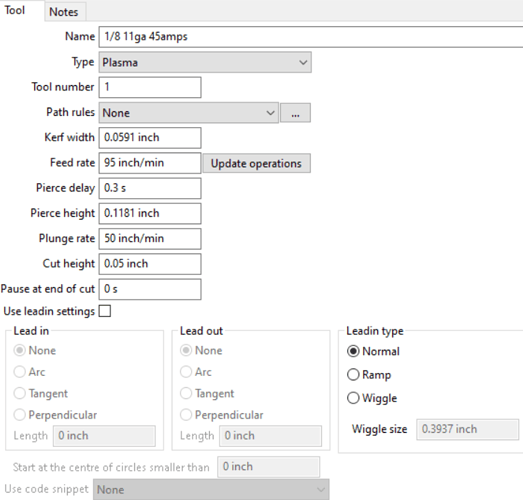

in sheetcam you need to set up your tools for cutting different materials…you need to set…pierce height…pierce delay…etc…

here is an example of a tool set

then fire control will start the program you load…and it drops the torch to determine where the metal is then raises a bit…and then away it goes…adjusting the height as needed…

Hello Toolboy,

Thanks for the quick response! I did purchase Sheetcam and downloaded the Post Processor from Langmuir per their instructions. So that looks good. I also set up my tools with the settings you mentioned. I created a test file to run different feed rates at a given amperage output from my plasma cutter (30 amps) to see what kind of cuts I get for a given material thickness. Once I power up my table and before I load a file into Firecontrol do I first have to manually adjust my Torch down just above the material for IHS? Or is that function (IHS) automatic upon loading a file into Firecontrol? If I understood your response it sounds like that’s the case and I’m good to go. Thanks.

I’ll try to give you an explanation of the IHS and THC functions.

The Post Processor inserts what is referred to as an IHS loop into the code, before the start of each cut loop. The commands are similar to those below with added explanations:

G92 Z0. - Set Z axis zero at the current location

G38.2 Z-5.0 F100.0 - Drive the Z axis down (up to 5 inches) until it opens the IHS switch on the Z axis

G38.4 Z0.5 F20.0 - Raise the Z axis (up to .5") until it closes the IHS switch

G92 Z0.0 - Set the Z axis zero at the current location

G0 Z0.02 (IHS Backlash) - Raise the Z-axis .02" to account for backlash

G92 Z0.0 - Set the Z axis zero at the current location

G0 Z0.15 (Pierce Height) - Raise the Z axis to pierce height

M3 - Torch on

G4 P1 - Pause for pierce delay

G1 Z0.06 F70.0 (Cut Height) - Lower the Z axis to cut height

H1 - turn on the Torch Height Controlller

Once the torch starts to move, the THC software takes the voltage reading from the torch and uses that information to keep the torch at the programmed cut height. If the torch speed drops below 85% (you can change this value) of the program speed, the software will turn off the THC and keep the torch at the same height until the speed goes above the threshold and the THC takes control again.

Hello ds690,

Thank you for the detailed explanation. It made the process click into place in my head. I appreciate everyone’s help in getting me familiar with how everything works and why.

When using the straight cut feature on Fire control, how does it know the cut height? Does it use whatever height is set when you start? Can you explain the process with and without IHS turned on?

Thx

The straight cut feature in Firecontrol generates a G code file with the pierce height at .15" and cut height at .06". There is no way to change that.

The IHS is what allows Firecontrol to set the Z zero at the top of the metal. I don’t know any circumstance where you would want to turn it off.

The Z zero that the IHS sets is what allows Firecontrol to know how high to raise the torch to get to the pierce and cut heights.

I recently turned it off when I did an edge start on 1/2 inch plate. I set the torch at 0.06 inches and ran the straight cut without IHS. It worked great and I didn’t run the risk of having the plate move by the torch accidentally bumping it.

Between that or using the nominal voltage with the THC.