Plasma cutter uses DC voltage. Work clamp is actually positive. Torch is the negative.

If you think you have EMI interference. Ground the table to an earth ground rod.

Not your electrical service ground.

805400r0 (1).pdf (236.8 KB)

Ya that is where its to technical for me. Your electrical service ground is a ground rod also.

not sure how the two are different.

@Knick, @Bigdaddy2166, @toolboy I guess I’m really just confused where exactly I’m supposed to ground my Primeweld machine to the table at this point…

Also, @langmuirsystems uses the terminology “ground clamp”, which confuses matters more, because I would assume this bonded ground wouldn’t also have a “clamp”, right?

@Phillipw, did you see my apology up there? Sorry!

Read over this.

805400r0 (1).pdf (236.8 KB)

Do you have your Langmuir table grounded as suggested in this manual, John? You’re making some phenomenally nice cuts, so it would be worth considering the extra work if you do.

Yes mine is setup just like the instructions from hypertherm. I’ll send you pictures in the morning.

Wow that’s a lot of reading over my head. So this is from HyperTherm, but I have a wimpy little razor weld.

All they said was flip up to turn on and flip down to turn off.

So let me ask you this can you have RFI and EMI problems and not have problems like error’s? Like maybe not give you a perfect cut?

and do you see this as being a problem with bigger amp cutters?

Most people don’t need to do this. But if you have EMI interference or have a tig welding operating at the same time. It’s a good practice.

That’s for all plasma cutters.

First let me say that if his silicone cup is being burned up around his tip cup. He is cutting way to high. A pierce height of .16 and a cut height of .06 you should have no trouble. You should have no slag except for the pierce location on the top.of your work.

!(upload://ohqZG5XiJnE6pvkmbPUByakC65E.jpeg)

I am very happy with the cuts I am getting so I am going to leave well enough alone.

If I start having problems I might look into doing something like that.

I will say this that is probably a 8 hr job by the time you tidy everything up.

thanks for the read though, always like learning new stuff.

There’s one thing I’m still struggling to wrap my brain around, so I’ll pose the question to all of you, but tag @ds690 and @Phillipw, since they’ve kind of been on the cut height trip with me so far…

Is backlash (not IHS spring-back but backlash) baked into the post processing in Fusion 360? Or is the IHS spring-back setting in Fusion a combined amount for material spring-back AND backlash? In other words, if I set cut height to 0.060" and IHS spring-back to 0, can I expect a 0.060" cut height on my machine which seems to have minimal (~0.005") Z-axis backlash? Or would I have to set a 0.040" cut height to make up for a 0.020" backlash being automatically compensated for in the post processor.

@toolboy , Good overview on the “grounding” situation. I personally fully understand the difference. I was responding to your specific question as to where it is stated by LS that (in their words) “attach plasma cutter ground clamp to the drain plug under the water table”. I will add that if LS’s intent was bonding to ground, their choice of words to include “ground clamp” is misleading. As I stated in my post, I don’t agree with that statement as written, just bringing forth where it could be found. Later -Steve

that is one i can’t help you with i very quickly walked away from 360 it is a very nice program, but it isn’t a standalone program. i try to do some of my cad work during my dinner break at work. no internet access.

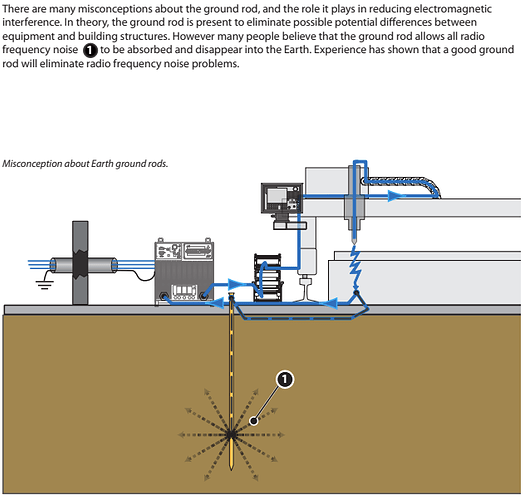

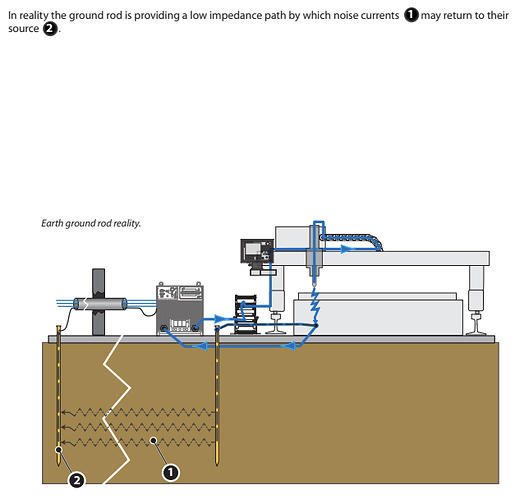

I been wanting to add these pictures in your EMF information for a while. @Bigdaddy2166

it explains the ground rod and its low impendence return.

I wish i could remember which manual it came from.

Maybe a old ESAB industrial plasma manual??

All steel buildings make the issue of grounding rods even more important.

You can run fusion in offline mode for up to 2 weeks before it needs to talk to the Autodesk mothership.

Sounds great. Be my guest. That illustration is as good as any. My shop is like 50 degrees this morning. ONE OF MY HEATERS FAILED OVER THE WEEKEND. Damn thing actually caught fire. Lucking the place is still standing. Looks like a new heater install is on tap for this morning…

To be honest I think this mod is the most helpful. This is a SS shielding tube that runs directly to the earth rod.

Where did you come up with that?

That looks like a easy install.

My brain ![]() Still need the earth rod. It makes a Faraday shield around the biggest culprit.

Still need the earth rod. It makes a Faraday shield around the biggest culprit.

That would be a little warm for Tin ![]()

Good luck with the heater install