You mount your torch anyway you like. When you screw it up I have torch heads in stock at $150 each.

@CrazyCasey

Quick and simple solution for you. Use the top and third from top torch mount locations. I run my 82i like this with the same style torch.

I designed and 3d printed this torch mount for my Tecmo machine torch. It completely eliminates the strap and holds the torch securely. The files are on Thingiverse.

I feel very dumb, @Neal…

Dont beat yourself up too bad. Happens to the best of us.

Cut some 3/8 steel I beam flanges today.

Everlast 82i 36 ipm, 60 amps, 1.2 delay

Cut height. .06 , peirce .16

Looks awesome, John.

So did you run this with the THC on, and if so, did you input voltage manually or use the smart voltage feature?

0.060” cut height, so assuming you turned off any spring-back, right?

And you said 36ipm; are you using feed rate optimization for the holes? And if so, how much are you slowing it down?

Thanks for posting!

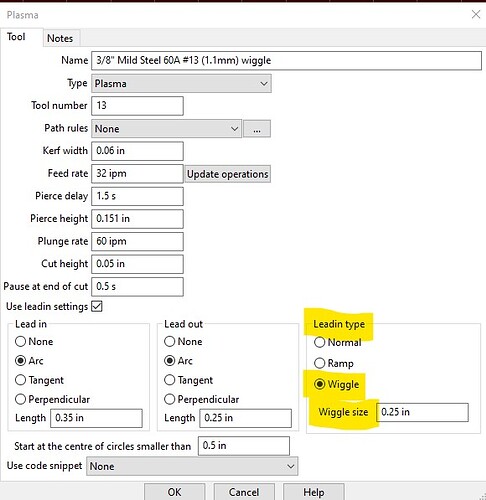

If your using SheetCam it has a wiggle setting for piercing that helps with consumable life. This is my 3/8" settings for my Cut60. Also slow down 60% for corners and circles, it’s a rule you can set in SheetCam.

I appreciate the settings. A beginner just wouldn’t even know this stuff if it weren’t for these forums. Thank you! It seems like I may need to consider investing in and learning SheetCam.

I don’t use sheetcam very much. Those plates were cut with Fusion at the settings I listed.

I almost always use the THC. It has worked flawlessly for me since I got the table.

Now I don’t cut out signs. So I draw it, post it, and burn it.

I have a similar setup and had the same issue you are having. It ended up being a ground loop problem causing the THC to float around and you really could not see it happening. What are you using for a computer? If its a laptop try unplugging every single cable except the USB cable and try it again.

I’m using an ASUS laptop and I never have it plugged in to power when connected to the table, so it’s only the USB cord, and the computer is over on my work bench, 5’ from the table.

Always connect your ground to the work piece! Better result by far . I’ll comment later as I read the rear of your comments. Note: I’m speaking as a 35year fabricator with no cnc plasma table experience;however, a lot of common sense!

Well that eliminates any ground loop issues. Did you get it working correctly yet ?

I hear what you’re saying, but I don’t typically question a manufacturer’s recommendation on a tool I’m unfamiliar with. Live and learn, I guess…

No, I ran out of steel and consumables. I’m going to reload on Monday, and take another stab at it.

I don’t use Sheetcam, what benefit does that wiggle provide on leadin?

Here is a little video I found it discusses wiggle a little bit and doing some thick cutting on stainless with ony 45 amps so it might show the op what’s possible with dialed in settings.

demonstrating wiggle pierce.

That’s incredible! Man, I hope to get there…