Well, my Everlast 62i plasma cutter showed up less than 24 hours after I placed the order. Gotta love that! But right off the bat, the air pressure DRO read about 6psi OVER what I had my regulator set to, which is somewhat problematic since they won’t let you run higher than 72psi through the cutter.

So, if I’m set to 72psi, I’m only going to have 66psi at the torch, which could be problematic on thicker material.

I called Everlast’s tech guy, who is very nice. He said that more than likely the gauge on my regulator is off. I told him that it was a very expensive regulator, and that it agreed with the gauge on my Primeweld plasma, and he said that analog gauges are notoriously inaccurate, and that digital pressure sensors are extremely accurate. Ok…

He had me run some tests with air flowing through the plasma cutter, and said that my 5 psi “air on” pressure drop was WAY TOO EXCESSIVE, and when I told him I had a $600 Motorguard 3 stage air dryer at the table, he said I needed to “get that off of there”, and said I’d never get the Everlast cutter to work properly with more than a single stage filter/dryer.

Anyway, I figured you’d appreciate all of that @TinWhisperer…

I guess I’m moving forward, but confidence is not high.

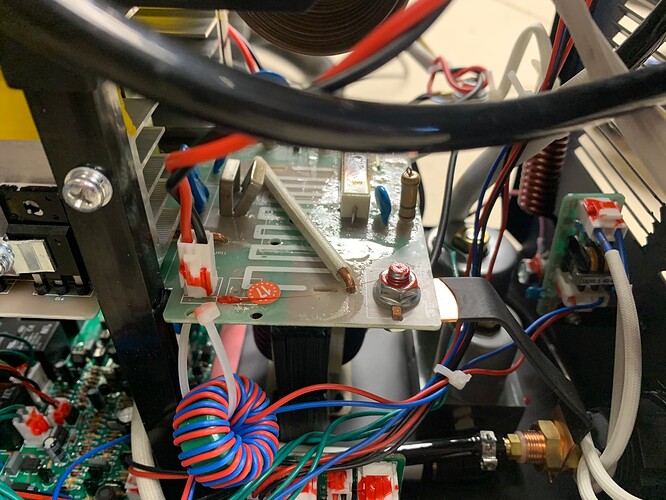

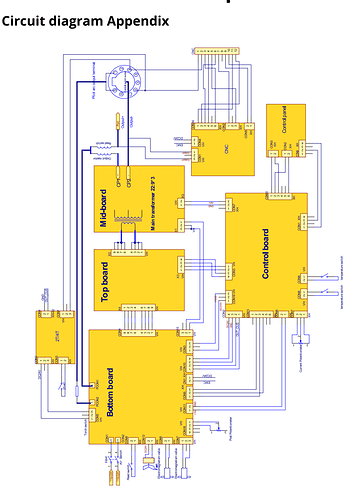

So, I’ve got the plasma cutter all wired up to raw voltage. I asked if I could do that without voiding the warranty, and he said they make exceptions for Langmuir customers, because of the Langmuir system’s voltage reading issues.

Anyway, I’ll make some test cuts tomorrow, with my way over restricted air setup and “problematic” CNC table.