Hello,

I am back with another student issue. (I am a high school teacher who is a plasma table novice, and this forum was very helpful last spring with our issue.)

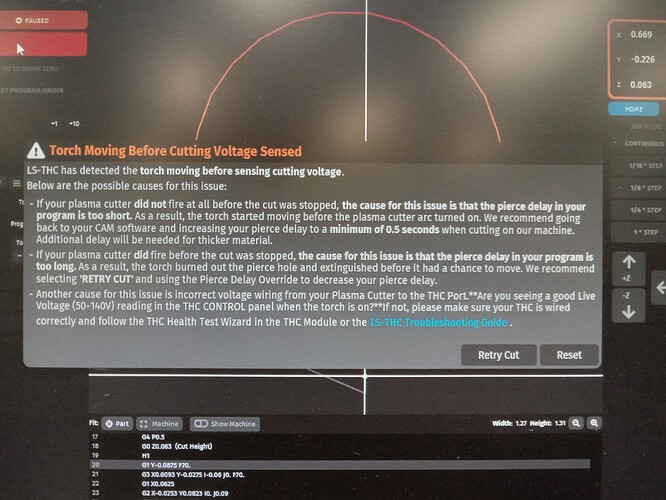

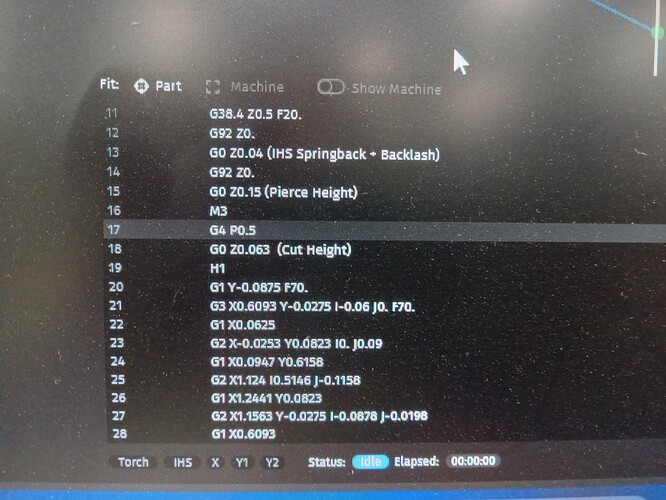

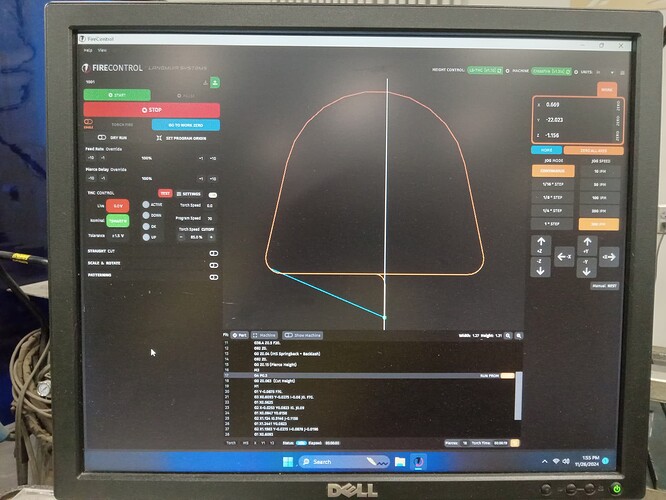

Our table worked fine in May the last time we used it, and now another student is having a problem with it. When he first turned it on, it needed a few updates, so it is now on version 21.1.5. The torch fires, but then stops without cutting, and he is getting the “Torch moving before cutting voltage sensed” error. I have read other threads on that topic, but we have still been unable to fix it. He has adjusted the pierce delay both longer and shorter - same result. We checked all the wires for a loose connection - they seem fine. We have a Razorweld 45 with machine torch. He can run the torch manually with FireControl, but running a program consistently produces the error.

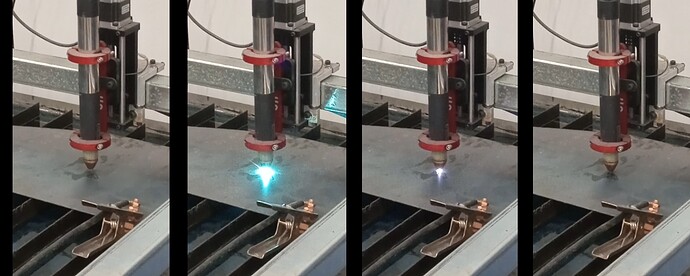

These are frame-by-frame shots of the problem.

Any advice will help! Thanks!

Check the wire connections to the VIM box. I recently helped someone and that is all it was.

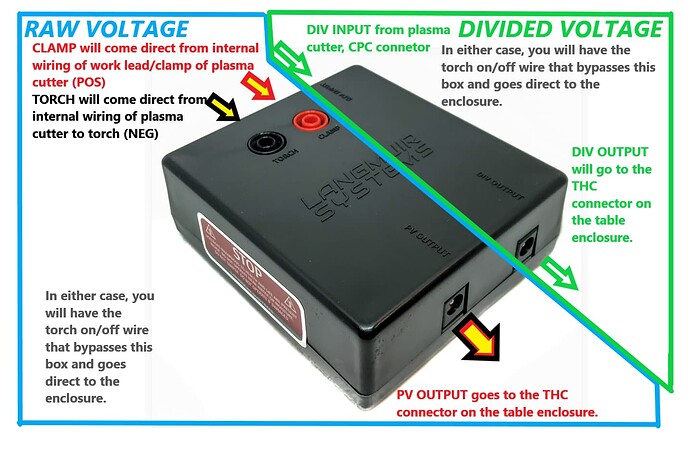

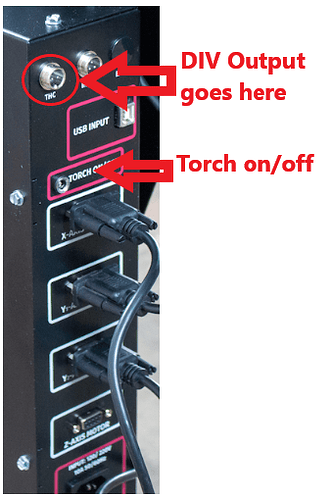

If you are using Divided voltage, which is looks like you are the input wire should go into the VIM box as shown in the area marked in green:

Check the connections of both wires and make sure they look good. You might check the wires for good continuity. And the wire going from this box needs to end up at the enclosure at “THC” (“DIV Out goes here”)

2 Likes

Your programmed cut height appears to be .103 based on your g code. That’s too high, you should measure the actual height your torch is at. I don’t have the test file handy but someone will post it hopefully.

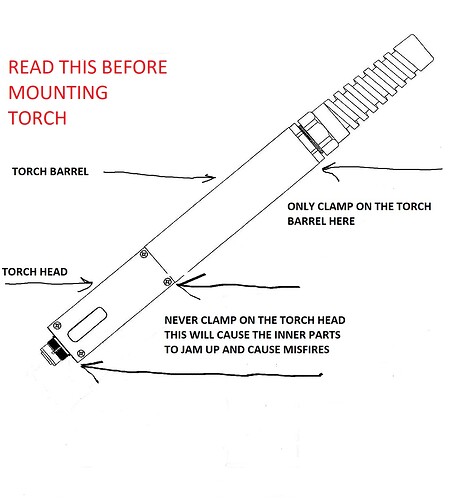

Second, your torch appears to be mounted wrong. I believe you want it clamped only on the silver portion.

The arc in the picture looks green, could just be the photo. What is the condition of the consumables in that torch?

It could be a wire or something, but those three things I mentioned definitely need to be addressed and could possibly contribute.

4 Likes

Is that torch mounted too low? I am just asking the group. I am not familiar with that machine torch.

Torch is mounted incorrectly. That could be the problem. Check the electrode movement like in the video. Hard to tell what type of torch you are using. If its a hypertherm you can disregard my rant.

1 Like

+1 to the other comments and also to add…

Has air pressure been checked?

2 Likes

Thank you all for your help!

It turns out we made two corrections, and now it is working.

ChelanJim We adjusted the connections to the VIM box. Our cord was coming out of the PV Output instead of the DIV Output, so we switched it to the DIV Output. It wouldn’t work from the PV Output. I’m not sure why we didn’t have the issue with it there last year, unless someone accidentally unplugged it and plugged it back in to the wrong spot.

brownfox We also adjusted the g code height from 0.063 to 0.05. We left the torch mounted as it is, since it worked from there last year. I didn’t check the consumables - they should be in good shape since we’ve only used it for mainly one project. Total time actually cutting since we assembled it is probably less than 30 minutes.

Bigdaddy2166 We didn’t take the head apart to check the electrode movement since the torch is working now, so I assume the movement is good. We have this torch.

TinWhisperer & Sticks We had checked the air pressure before; that was good.

3 Likes

You should inspect the consumables, never assume they are fine based on cut time. Too many variables.

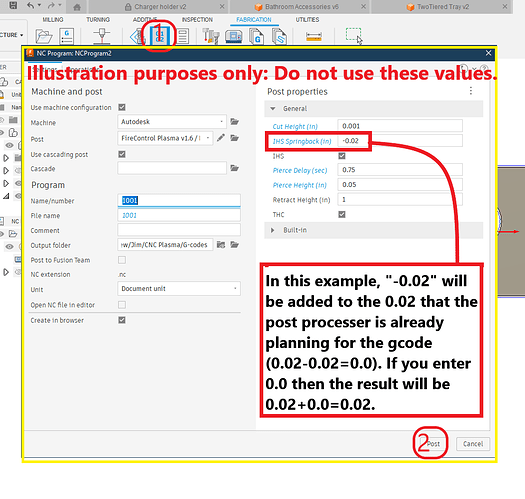

Also, changing your programmed cut height to .05 may not help much. The firecontrol post automatically adds .02 spring back/backlash. You appear to be adding another .02 in fusion. I would recommend not adding anything extra in fusion, and setting your cut height at .06. You then need to verify the height you are achieving with this setup and make adjustments accordingly.

1 Like

I often suggest to label all the wires. I love labels because I forget things. And in your setting, there are lots of different people (more than just you) that might ‘accidently’ pull a wire loose.

Glad you got it working. BrownFox’s comment is right on, in the post processor of Fusion 360, if you enter 0.02 in the springback, Fusion will add that to the 0.02 inches that the post processor was planning to add. Here is that screen:

1 Like