I am a high school teacher, and one of my senior students is having an issue when using Fusion 360 and FireControl with the CrossFire Pro. He has several different design files that are all sections of a continuous sign. They are all supposed to be the same height, as he designed them on Fusion 360. However, when he loads it into FireControl, the heights change up to 1/4". For example, 14.00" changes to 14.25" for one section, and it changes to 14.05" for another section. They can be a little different than the original height, but they all need to be the same as each other so they line up. Any ideas on why this is happening or how to fix the problem? Thanks.

Welcome to The Forum.

So when you cut these parts they’re out of dimension by this much?

Or are you saying the total outside dimensions and fire control are showing larger than the dimensions in Fusion?

The dimensions showing in the bottom corner of the visualizer and fire control may not act accurately represent what they finished dimensions would be. The total dimensions may add a couple other factors in like where your stock box point origin is located and how the setup enveloped the model. Another factor would be your kerf width would likely be added to the outside dimensions

If you’re uncertain I would cut a few 2x2 test squares and check the dimensions before cutting any larger projects.

Once you’re able posting an f3d file would be a good thing too then we can look into your Fusion file

Yes, as Tin said: “Welcome to the forum.”

One thing I have heard is that the decimal point is very important. If the dimension, in Fusion, is actually put in to the hundredths place, as your example states ‘14.00’, then it should be solid and remain.

Example: Let say your student is using some multiplier and the actual value he is using is 7 inches and he puts “7” for the dimension. That does not lock down the decimal places and Fusion may move it a smidge one way or the other but it would still be considered “7” by any rounding method. Multiplying and dividing that value can amplify the issue and cause something like 14.02 when you expected 14.00.

A full 0.25 inch difference needs more exploration.

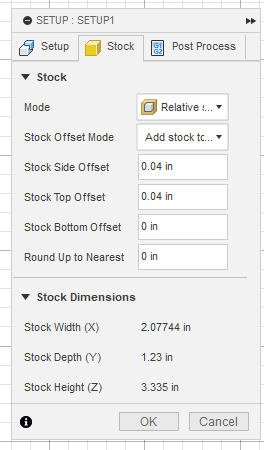

As Tin notes, there may also be a difference in the perception of the “stock piece” and actual part that is cut out. The stock piece takes into account for the margin/offset between the edge of the metal and the actual cut line of your part. That is decided by the second tab in the Manufacturing Set-up.

He hasn’t tried cutting anything yet because he has noticed that the dimensions are off. I will have to have check with him on your questions/comments and respond to them later. Thanks for your input! I haven’t had much time to work with it yet, but he assembled the table and has taken the lead on initial training and the first projects.

I think the lead in or lead out may be adding to the dimensions once it’s in firecontrol. I can confirm this later when I load a program.

I would say 100% it is the lead in, and outside offset of the kerf.

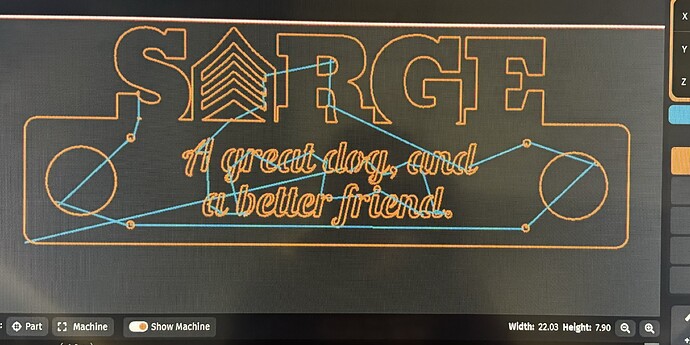

My design is 22x7.87.

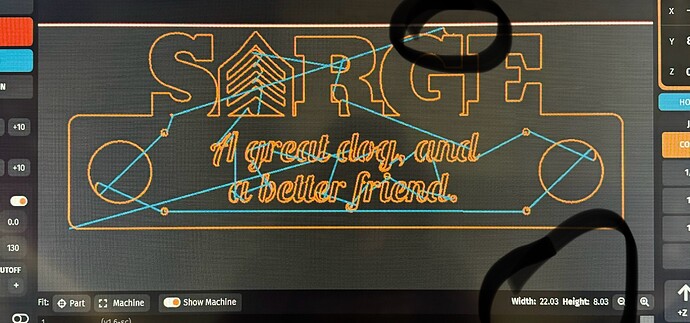

Post processing in sheet cam my normal way, then I did an alternate version with a long lead in that I purposely put in a spot to go beyond the outer perimeter.

It increased the dimensions accordingly. I also noticed the width became 22.03. My kerf is set to .029 so I would have expected the file to become 22.06. Surely this is incorporating the outside offset.

Normal file, lower height.

Test file with purposely large and out of place lead in to increase size.

That makes a lot of sense. especially since it was not consistent for the OP’s student.

You changed your profile picture again!!! ![]()

I liked his old one. I knew it was brownfox before I even read it.

I agree! Bring back the Fox! Bring back the Fox!

Unless… the Fox didn’t have an unfortunate mishap, did it? ![]()

What happened to the rule that all profile picture changes had to be approved first by BigDaddy and his chihuahuas?

Yeah, like Jimmy said.

Having Brownfox on the forum is like the other bookend to the TinMan. It’s like having NASA on one side and SpaceX on the other.

Yep! You got that right. Once Brownfox started talking, I knew it was really him. Always good information.

Oh now you’re just being ridiculous lol. @TomWS im taking an extended break. The whole business thing was taking way too much of my attention without enough of a benefit to offset what was being neglected.

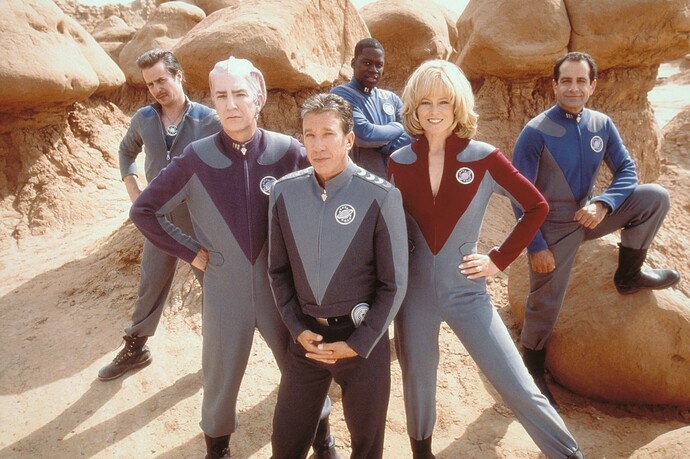

Which one of you is Sigourney? That’s Jimmy in the middle.

You guys are too much!

I am likely ‘Guy’ that has no last name and is likely to be written out on the next episode. ![]()

Loved that movie!

That’s ok, we weren’t really interested in you, we were missing your Fox Avatar! ![]()

@DakotaEngineer Welcome to you and your students! Hopefully we haven’t totally driven you away with our nonsensical posts. Normally we try to be helpful…

My student read through the comments and they helped; I will try to address any comments/questions toward me as best I can.

TinWhisperer - The total outside dimensions in Fire Control were showing larger than the dimensions in Fusion. We haven’t cut any yet, but we may try one this week. I will see if I can post an f3d file.

ChelanJim - I think he was using decimals to 2 places. He did look at the Stock Piece tab and noticed it seemed to be adding some extra material there, so that screen shot was very helpful to him. He adjusted that, and now the measurement only increases an addition 0.06 inch, so 1/16", which would probably not be noticeable.

brownfox - I will check with him further on the lead in, but I don’t think he has any set on the top or bottom of the cut parts.

TomWS - Thanks. You haven’t driven me away, I just don’t always respond that quickly, and my student has been the one learning the machine and program - I haven’t had much opportunity to do so yet. This thread has been helpful - the project may not be perfect yet, but we have it down to a manageable difference.

Thank you all!