The torch is like 1/2 an inch off the sheet metal. Its like thc works for a small piece then stays 1/2 an inch off the surface. It goes down and touches but raises up to far to cut

Two things to try:

- Look at the gcode to verify that you have the right settings. If you don’t know how to read it, someone would be happy to look at it to see if it is saying what you meant to say for cut height.

- Run the test cut height file that @Phillipw made. I am not at my computer so I can’t retrieve the file right now.

Here is a link to a previous post that explains the process to check the cut height.

Btw, how thick is the metal? If it is thicker than 10 gauge, you don’t need to have any “spring back” in the past processor.

Do you use SheetCAM or Fusion 360? I know you have posted before… I just don’t remember.

Double check your cut settings, sometimes a misplaced decimal point can drive a person crazy. I’ve accidentally put 0.6 instead of 0.06 cut height, took me a while to figure it out. It behaved exactly as you described though.

Hey Jim - I just ran the cutheighttest.tap file and measured .156 from the torch to the plate when it was done. Ran four time. All about the same. Now what do I do?

Phil

First questions: What is your cut height suppose to be? What was the gcode setting? What cutter are you using because if it is the Hypertherm SYNC, it would necessarily be an entirely different setting?

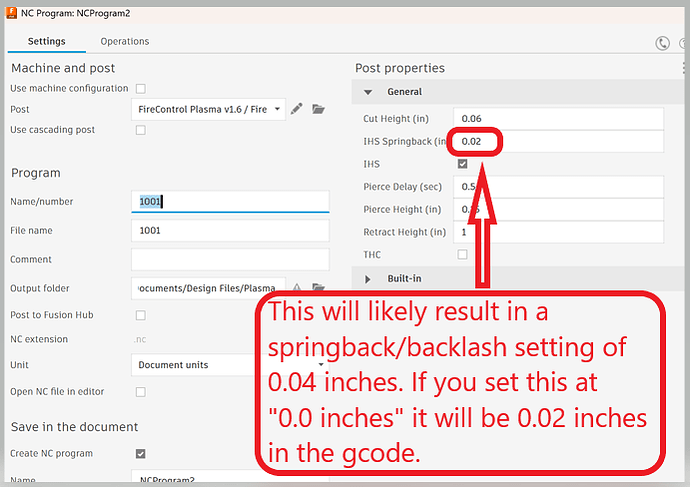

Look at the first 20 lines of your gcode. There are two different numbers that are affecting this cut height: 1. “cut height” and 2. “springback/backlash”.

Third question: Are you having some cutting issues?

After we have that information, we can go from there.

Hi Jim. Maybe I misunderstood what the test file does. I thought that it was a self-contained, properly written, g-code file to see if my system was responding correctly to a command to go to .065 cut height. I just downloaded it from the web and then loaded it into Firecontrol like I would any other cut file. I didn’t do anything to generate system-specific g-code or change any of the Firecontrol defaults. On the screen, IHS Backlash is set to .02, (pierce height to .15, but that shouldn’t matter for this test, I think). My cutter tip ended up way high , about.156, when the program ended.

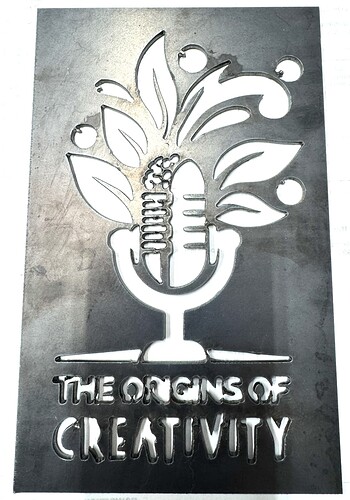

But yes, I am having cut issues in general. Big, fat, sloppy cuts. Even with new consumables, it looks like my kerf is about 1/8”. It seems ok on large profiles, but anything small is way overcut. I think it is cutting from too high. I have a 15 year old Hypertherm Powermax 45 with probably less than a couple hours of actual cut time on it. I have hand cut things here and there as needed over the years, but not much. Just got the Crossfire Pro. The only CNC cuts I’ve made so far have been with THC off, and using fairly small, flat 14 ga sheet. (Something is weird in my 50:1 voltage because the Firecontrol screen shows 0 to 10 volts when it runs. I haven’t pulled the cable to put a voltmeter on the cutter output yet. I’m using Hypertherm’s CPC on the back panel.)

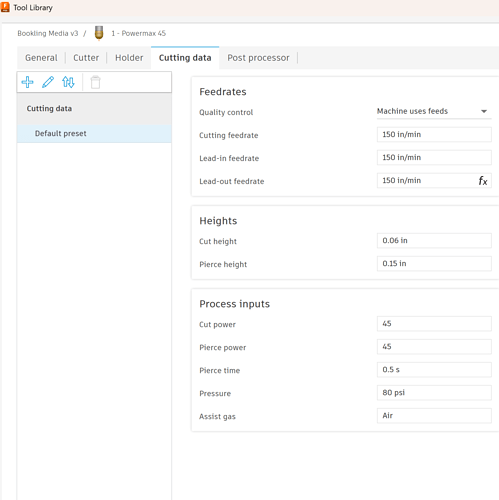

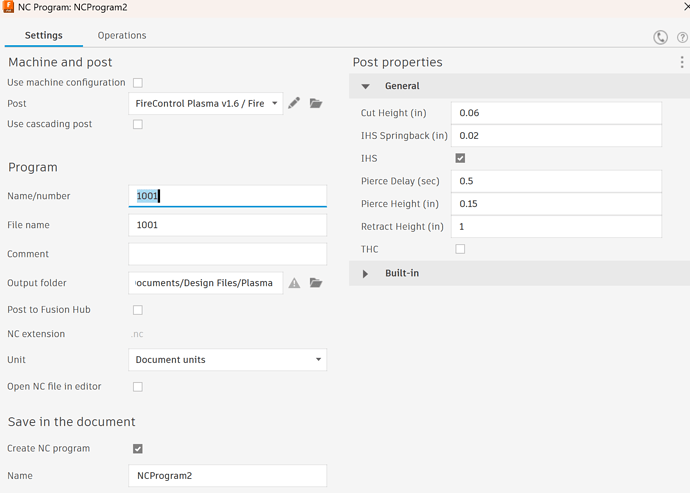

On a bit of a different topic - when I create cut profiles, Fusion fails to pick up details of the cut when I select lead-in and lead-out, even if the item is not particularly small. As in, there would be plenty of room to do a lead-in cut. I either uncheck lead-in or sometimes tell it 0” to get it to work. The result is a lot of pierce nicks in the edges of my work. Attached are some screen shots of what I generally try to use for setup and post.

I have to do a lot of test cuts at different feed rates, etc still, so I’m not really expecting an answer to all this. I was just trying to figure out how to use the height test file.

Thanks!

Phil

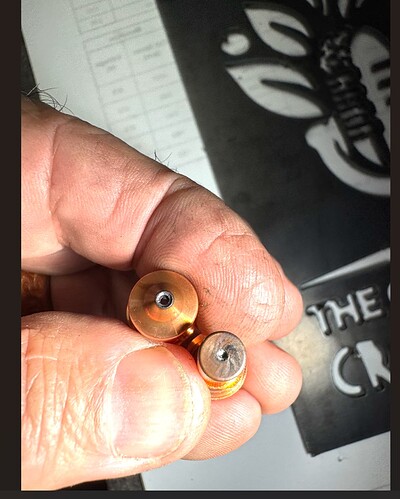

Picture of how you have the torch mounted. Just do a straight line cut about 4” long stop in in the middle check the height if its to high the torch needs to be moved down in the holder. The cutting tip need to be replaced the electrode can still be used.

Thanks, George! The nozzle has about ten to twenty running feet of cutting on it. Hopefully I can figure out how to make them last longer than that! It’s a hand torch, original Hypertherm. It’s down as far as it will go.

Phil

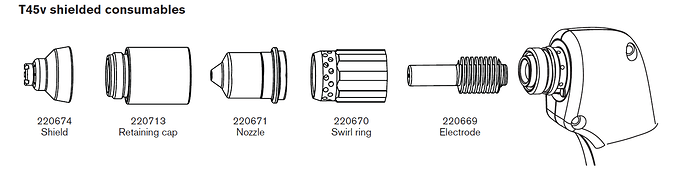

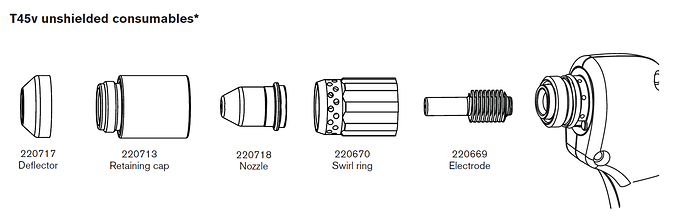

That looks like a drag shield on that torch is it? If so then you need to get a cnc shield. Just loosen the thumb screw and drop it down some.

…. uh …. probably …. I don’t know the difference. But I’ll look it up.

Like I said, original 15 year old equipment. That could make a huge difference. Thanks, again.

No you need the 220817 CNC shield. The rest of the consumables are the same as you have.

Yes. The file is showing you what your cut height, in reality, will be when the cut height is set at 0.060 with a 0.02 inch backlash setting.

When I was asking about gcode file information, I was trying to determine what you were putting in those parameters for your design files. Just to be on the same wavelength.

George is giving you good advice…let’s stick with his line of support right now. He knows what he is talking about.

Edit: One final comment for now about Fusion and the Post Processor.

Glad you’re here. I didn’t find that number anywhere.

Thx

Let me chase down George’s suggestion and check back later.

Thx