assuming anything is dangerous… that was a joke

I’m sure its the fire control software and the THC, the bad bevel is on 14 gauge and gets better the thicker you go up in material size, 1/2 thick steel the cuts are almost perfect with little to no bevel.

can you screen shot your cut settings for the you may have something wrong with the cut settings. a decimal place in the wrong spot or something.

Nothing is wrong with the my numbers, it is the smart voltage that’s the problem, says it cant be used on anything less than 14 gauge , well that’s not true because it wont work on 14 gauge and only way to get clean bevel free cuts is with nominal voltage on that thickness

not saying anything is wrong. the thing is if you don’t start the cut height right smart voltage will never work. you need to check your cut height then correct it in your cam. i have mine set a .046 ish to get a actual cut height at .060… it may be worse with thinner material because it will bend.

I will have to wait until I’m back in shop for some trouble shooting. I’ll be back…

I would remove the rack and lower it about a half inch. You are very close to the point where it will trip the IHS switch and give a false Z zero.

Thanks ds690, I had it lower than that and last week I redid the Langmuir instructions again and this is where I wound up. I will definitely lower it again. I had to fly out today but this morning I tried cutting again and after a few checks I found a couple things that I did not understand.

1 my tests showed again that EMI was non existent and my live voltage was at 0. Prior my voltages on the THC Live voltage have been showing around 9v while nothing working? NOTE: I have all new cables and the Langmuir THC box. Shouldn’t that always be ZERO?

2 I ran a few test runs again and the nozzle was exactly where it was supposed to be (around .050"ish) but then after a few holes it cut it was right back up to the .115" range.

Does this sound more like noise? I hate to chase my tail on this. I plan on getting back in 2 days and will run a ground wire to the chassis and gantry.

Sorry about learning on the fly but I have a ton of time in this and struggling a bit.

Who ever put out that voltage video that was really awesome!!

The resting voltage should be as close to zero as possible. Mine fluctuates between zero and .9 volts. It has been worse in the past and I can watch it change as I move the work clamp cable away from some of the other cables.

If that phantom voltage changes during a cut, it can cause a change in torch height with Smart Voltage. For example, if your resting voltage was 9v at the start of the cut and the Smart Voltage detected 130v at the start of the cut, it will use that as the target voltage to maintain the cut height. If the phantom voltage drops to 3v during the cut and that reduces your cut voltage to 127v, the THC will raise the Z axis to try to get back to 130v. Once the THC takes over, the cut height that you set doesn’t matter any more. It will raise or lower the torch to try to maintain the target voltage that it detected during the first .25" of the cut.

Thats great input and gives me something to look at. I am confused where it would be seeing 9.2-9.7v resting. It has to be a massive noise interference but in my mind 9v is really high interference or not. I have 3d printed some cable holders for the motor and I am also thinking about removing the torch lead from the cable chain. I am a little new to the plasma table but I would thing this would be a NONO to run that with the motor wires to the gantry? I already have a separate grounding rod for another CNC I have so I will try grounding this thing first and see if anything changes. Thanks again for the input.

OK guys I am sorry but now I am super confused and a bit frustrated. I just grounded out my entire table including the gantry. I ran the THC tests and everything looked great at 0v resting and about 135v tested. I made a few cuts and once again the torch is way high. Now my resting voltage is in the 50v range. If you let it set for a little while and not touch anything it will drop into the high 20 to low 30v range like a capacitor is releasing energy. What the heck am I missing?? Could that divider box be defective??

I would like to say about 3 weeks ago I cut a 1/4" piece and it cut perfectly. All the holes were round and without angles so what the heck has changed?? I keep wiggling wires and you think the voltage starts to change but it doesn’t… Anything that you can think of??

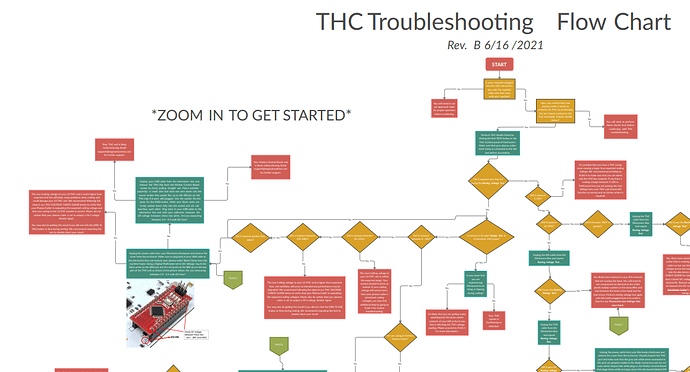

There is a THC flow chart on here I recommend that you go through it. I have very good detail in troubleshooting.

So usb cable isn’t touching anything? Have you changed any wiring? Have you tried ungrounding your computer?

Also make sure your USB port on the control box isn’t touching the metal box.

No sir I have changed nothing on this table. I do not have anything touching that I see. If I unplug the THC input cable the voltage drops to 0. If I unplug the output the voltage seems to double from what is was. If I let it set for a while the voltage goes back to zero and all the tests return to normal. I then try to run a test piece the process starts all over. The torch is way high the voltage is in the 50s and nothing cuts right. Either I have a bad cable or this box is no good??

Also I have checked the USB to ground several times with no issues.

Do a search on here for the THC troubleshooting flowchart. Ls put it together follow the instructions to a t it will show you where your trouble is… Well in good theory. No it should help you out.

HEHE in theory I should be cuttin some steel ![]() . I am struggling to use the chart on the web because 50% of the time it passes the tests and the other 50 it doesn’t. Going to make it fail and try to follow it that way. I did start a ticket with Langmuir and will be interested to see if they respond. Thankyou for the help

. I am struggling to use the chart on the web because 50% of the time it passes the tests and the other 50 it doesn’t. Going to make it fail and try to follow it that way. I did start a ticket with Langmuir and will be interested to see if they respond. Thankyou for the help

Are you using the chart that starts with checking voltage at the plasma?

Forgive me if you have already shared this but what plasma are you using and how are you getting the voltage from it?

I have the Hypertherm 45XXP with the Langmuir THC box and OEM cables. I started using this guy to test.

That would be it. If you are getting a pass and fail. You may want to check your cabblrs good to make sure you don’t have a short as well.

Well it looks to be the controller according to this chart. I desperately need to cut something as well. I emailed them and hope they will respond tomorrow

you can cut with the thc turned off should get you through…