I have a Gen 1 machine that I just upgraded to Gen 2 with THC. I am just trying to figure out how to adjust the torch height during cutting. I have been using Sheet CAM and of course with the Gen 1, I never needed to worry about it, other than setting it to “0”. Do I adjust it in the program or is there something I need to do in Firecontrol? The problem I am having is that it is hovering over the work at about 1/4" and is not cutting anywhere as clean as before. In fact it mostly is not even cutting through the material. THC is a whole new world to me, but is cool as hell. Thanks in advance.

Is your computer plugged into a grounded outlet, and what is your live voltage reading?

Most of the time, this is because your torch mount is too high in the Z-carriage. The Z needs to be able to continue to travel down after the torch contacts the material, so it can trip the IHS sensor. If the Z bottoms out before the IHS switch is tripped, Firecontrol is not getting the correct information about the material height and is setting the pierce and cut height based on that incorrect information.

Loosen the clamp on the torch mount and lower the red piece, so it is only sticking above the carriage by about 3/4" and try again.

It’s a laptop and yes it does have a grounded outlet. The live voltage was 74.5 when I tested it.

Unplug the laptop and try again. If your torch isn’t touching the workpiece during IHS then you need to lower it in the holder.

play safe…unplug it or get a ungrounded plug adaptor…

also is your work clamp on the metal?

I have a question with the same issue. It almost sound like when the torch comes down to touch the steel it lifts the head off its seat and the voltage changes but then it sounds like the Z motor continues to push down like its not contacting the top of the THC (hope that makes sense) so when it starts the cut the head is over .250" off the work piece. All the tests are passing and when I lift the torch manually the IHS turns green so what zeros the head off the work piece? Yes I have grounded outlets and I would think the piece is grounded as it does cut it just cuts really bad. I cant understand why the Z motor continues trying to push the head down once the torch lifts from its seat??

Just something I noticed is I stopped a cut and I see that the torch is about .250" above the work piece but cut control says it is only .030". I have got to be missing something super easy.

Is there still room for the Z axis to travel down after the Torch touches the metal? When the Torch touches the metal, the Z axis continues down until the IHS switch opens(green IHS light comes on). Then it raises back up until the switch closes and sets that as the Z axis zero. Then it raises to the pierce height that you set in your CAM setup. That should be around .15".

What do you have your pierce height and cut height set at?

Hi, yes to all the questions although I am not 100% if it is the correct height when it is piercing? I even lowered the Z axis down at a very low rate and you can see the steel push down and I have a bit of travel left in the height. I set the cut height to .030" just to try it and it is still .250 when cutting. So how can I tell when cut control zero’s out the Z height?

What kind of Torch are you using? I suggest lowering the Torch in the mount, so that you have at least 1/2" of remaining travel in the Z axis.

This is how the system works:

A command is given to drive the Torch down (up to 5 inches) until the IHS switch opens.

When the switch opens, another command is given to raise the Torch up until the switch closes.

At that point the Z axis is set to zero.

Then whatever backlash and springback compensation you set is added to the Z zero and a new zero is set at that point.

Just noticed that when it starts cutting it flashes UNDER TORCH HEIGHT CONTROL in the Z axis window? Is that normal? I see the IHC flash green really quick then start cutting.

Wherever the THC takes over, the Z axis field will say “under THC control”.

Are you using smart voltage or setting a nominal voltage?

Thank you. Smart Voltage I think as it says Smart in the window. I was a little confused on that but now makes sense. Can you lead me to a link to set that explains how to set backlash?? I see a basic explanation in Langmuir’s sight but nothing to adjust it. Now that you said that I see that the default is set to .250" which could be the entire reason for this. That would make sense although I am not sure why the default would be so high. Thank you for explaining this.

I’m assuming you are using Fusion, since Sheetcam doesn’t have any settings for that.

My testing has shown that no backslash compensation is needed. However, the post processor automatically adds .020" off backlash compensation. You can reduce that by setting the springback value to a negative number in Fusion.

Thicker metals don’t spring back, so no compensation is needed. On thinner metals, that .020" may be needed.

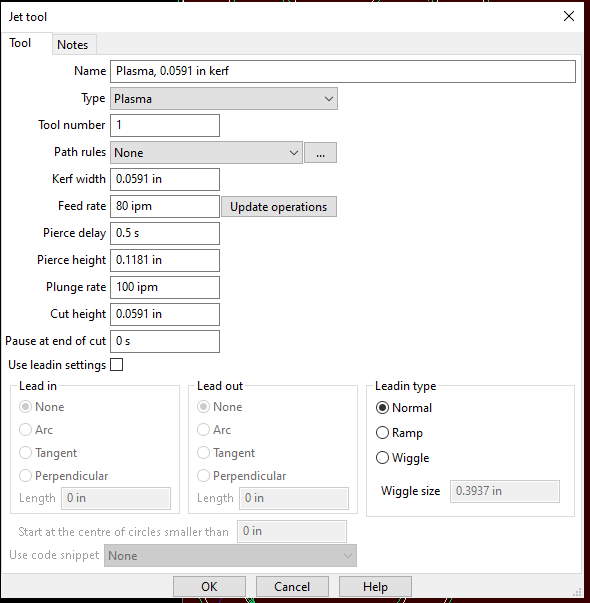

I am using Sheetcam ![]() I see this compensation in Cut Control though? Should it be set to Zero?

I see this compensation in Cut Control though? Should it be set to Zero?

Sorry I am looking at Smart Voltage Travel in Cut Control which is probably different. I am now confused why it is compensating this so high. I totally get what you mean by adjusting up the torch height but I would think the IHC would never turn green if there was no more movement left but I could be missing something. I will move it and see what happens.

I have a couple more questions that might be covered elsewhere so I apologize.

- When I pause the cut the Z axis actually shows that the torch should be at .030" (assuming above material) but the head is a lot higher and then when I hit resume the run light starts flashing and says Running but nothing happens and then it faults out saying Cutting Voltage Lost During Cut, so I am assuming this is a Langmuir programming issue as the resume just doesn’t work or I am using it wrong??

- When I hit stop instead of pause the Z height goes from .030" to whatever number the torch is at from when I zeroed all on the machine work zeros. So I would be confused if the THC zero’s the head during the run state shouldn’t it still show .030" and not change??

Sorry I am terrible at explanations!!

The IHS light will come on when the Z axis carriage bottoms out, even if the torch had not contacted the metal yet. If that happens, Firecontrol well set the zero when the Z axis bottoms out. This could leave the torch way above the work. That is why the location of the torch clamp is critical.