My understanding with the wiring is that your torch lead and ground cables shouldn’t touch any other wiring.

Also may be worth while to call razorweld and talk to them too.

TW:

Honestly don’t recall but will start paying closer attention.

I have been having problems off and on from the start. I have NEVER owned or operated a CNC anything then add on the CAD/CAM steps which was quite overwhelming to say the least so I have always contributed my problems to my ignorance and inexperience.

Wildstone:

Going to unwrap my leads to the machine torch and see if it helps but wondering how others get the THC leads to the head without being close and/or touching the torch lead?

There shouldn’t be any problem with running the torch lead and IHS wires together. I have the torch lead, IHS and Z axis motor wires all running together with no problems.

The issues start when your Plasma work clamp wire and torch lead cross each other and/or are coiled.

Okay. I do not have them coiled but uncertain if they cross at any point. I will double check tonight to ensure they are run properly and not crossed.

I have had this happen a couple of times. I was under the impression that this was an interference issue… but I am using a Prime weld Cut 60. I updated to the newest fire control this week. I am currently running the torch lead and and the IHS wires on opposite sides of the pole but I was skeptical that it actually does anything and would tend to agree with @ds690 that this should not matter. I have also added additional ferrite chokes to the USB cable. The last two times I have used the table I haven’t had any issues. I have also recently wired the THC to the raw voltage. If it happens again I will probably call Primeweld and see what they suggest. Definitely adds to the stress when starting a cut on a $200 sheet of steel.

TW:

Firecontrol froze up and does NOT continue moving along it’s path.

The same error shows up that starts moving before voltage is detected.

Do not know what you mean by “Does your THC pass it’s test within firecontrol?” How do I test it?

Have not tried an older code because they all seem to throw an error from time to time.

Is it possible that it’s worn consumables? After all the testing I have been doing I have 105 pierces with a cut time of 20 minutes.

https://www.langmuirsystems.com/thc/guide

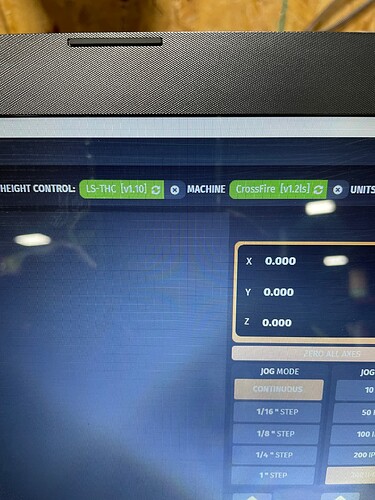

Is this green light highlighting in fire control for you.

I’ll try to find that test button in fire control and screenshot it when I get back to my shop computer.

I linked you the torch height control manual from langmuir I’m sure you’ve looked through it but the links there for your reference.

Yes I have looked through it and nothing jumps out at me.

And yes both green buttons are lit.

Only thing that makes me wonder is should something be connected to the Raw Voltage red and black jacks on the VIM in addition to or instead of the factory plug going into the RW45?

That picture looks correct for divided voltage.

the other ports are for Raw voltage which you are not using.

Hi,

I’ve had a similar issue recently. After a bunch of trouble shooting and forum reading I discovered a bad solder connection in one of the THC cables.

Run the continuity/voltage checks on each cable and connection to make sure signal is flowing.

-Derek

Great feed.

Im having the exact same issue. Was cutting fine last night, electrode went bad, replaced (found the electrode unscrewed rather hard after it went bad) then torch would fire, plunge down and stop firing. I also tried with THC turned off and it would cut fine.

Which cable did you find bad. I am using a machine torch. Curious if the heat from the electrode going bad had a negative effect on the machine torch internals??

check the plunger action of the electrode…it should easily push in and out…if it does not you have overheated the torch head due to lack of post flow cooling…

you might be able to retap the thread into the torch…but if the plunger action is shot then so is the torch internals.

Thank you, Plunger does move freely.

However when sitting idle fire control shows 7 volts at torch, I don’t recall seeing this before.

Took my machine torch apart, moisture (water) within the housing.

dried it and cleaned it all up, drained my water Seperator and copper pipes, powered everything off and back on and it appears to be working fine now.

Incidentally, this was an unnaturally humid day which ai tend to avoid when cutting.

And big thanks to all who help and are kind enough to continue to assist with answers to questions that have for the most part been asked many times on this forum…

Sounds like you live in a place like me… I can use my air compressor as a pressure washer ![]() .

.

You may want to look at upgrading your drying system if that much moisture makes it through. It will eventually trash your torch.

water in the houseing would be caused by splash back…niot by damp air…if you had that much water in your air your torch would burn out and blow the tips…

watch your post flow cooling…let it run for 30 seconds if you can adjust it…or place a scrap metal under the torch when you finish cutting…

I’m having the same problem, I have an evergreen 62i. Last time I used it was about 3 weeks ago, and it work fine. Today I was planning on cutting a 16 GA sheet. I loaded the program and it fires the torch, but it stops. It gives me a message, if the torch didn’t fire then this, if the torch fires the is this other, related to the pierce time. I use fusion 360 to create the code, I don’t change the pierce height or time, I keep what is recommended from the videos in Langmuir. I’m using new consumables. Any ideas what it might be

I just try cutting a straight line using a 0.5 sec piece delay and 110 ipm and it work.

OK…as a 62i owner I can hopefuly help…

there is a checklist I use if things go wrong…

- check ground location and clamp

- check air pressure and moisture control

- check consumables and swirl ring for wear and replacement if required

- check plunger action of electrode to make sure it spring in and out

- check Everlast screen for any error codes

- make sure spring loaded safety pins under torch head cup are lubricated and spring in and out

Even if the torch did not fire do you hear air?

- use Firecontrol and test fire the torch to see if you hear air or what happens

- plug and unplug the torch fire on/off cable from the Langmuir box and replug it…this sometimes comes loose.

Toolboy, do you have an email where I can send you a small video I took. I was able to cut section 1 of 6, but I had a lot of stop and go, has to retry again.

Thanks