Are you using fine cut consumables or regular 45 amp consumables? I know above you stated only about 500 pierces but could you take a picture of the nozzle end it should be perfectly round. Also are you running a cut height of .125? +/- I know the sync’s cut height and Pierce height is almost the same from the cut charts.

Fine cut. 30-45 amp Yes I will. That pierce count is total count not just on the fine cut. I am running a piece height of .120 and cut height at .060

Still check to consumables orifice roundness regardless.

Also check out the mechanized cutting guide and the cut charts for your machine.

https://share.google/jSSzC1F4qrZ4v8wac

GDE_810500MU_R4_45SYNC.pdf https://share.google/KLJAA1lyMMloWNPyL

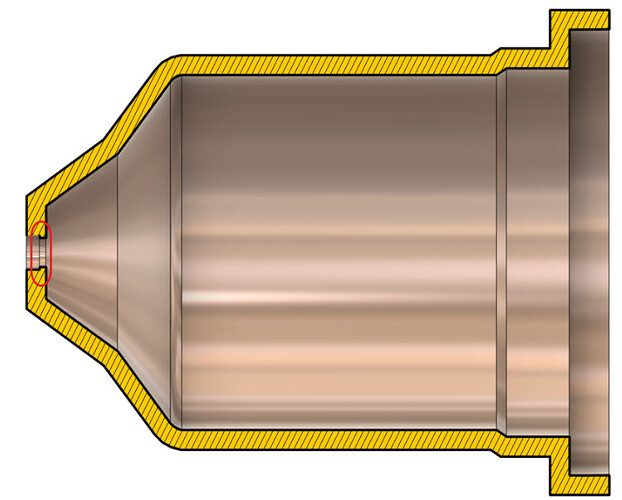

I know it might sound too “critical” but that tip/nozzle is losing its roundness. Compare it to a new one.

I once had a nozzle, that I swear was perfectly round. I was having trouble so I compared it to a new one and it was definitely showing the wear. The new nozzle fixed the issue.

I am not sure on the SYNC version but on the standard Hypertherm nozzle there is a step inside. I will try to find a cross-sectional view, but inside, the channel is slightly smaller than the outside profile. Once the step is worn down, it is a totally different plasma operation.

Here is the picture from Tin’s post:

Hahah my eyes can’t zoom that much, but thank you. So that could explain a bad cut but still need to figure out what’s causing the dive during cut.

And yes the SYNC machine is a slightly different animal, it records the cutting data. Counts the Pierce’s and cut time per nozzle assembly and yes the WHOLE thing, I do not like the ability to not change out certain parts like regular nozzle consumables. These float around $55-$60 per nozzle, so when one messes up that’s a chunk of money instantly gone. Not just the tip or swirl ring or electrode the whole thing.

Supposedly this design helps to protect the components of the assembly from accidents , but again if it’s not programmed correctly your still guna mess it up.

Yep…like most all things, there are trade-offs.

How many pierces are you averaging?

For over a year, my friend was getting between 1,900 - 2,200 pierces on each cartridge on his 65Sync.

He ran mostly thinner material so he always ran Finecut. He’d mix in some 45Sync consumables as well as they would be on sale from time to time.

Still got some old screenshots or his pierce counts from the app before he switched to laser.

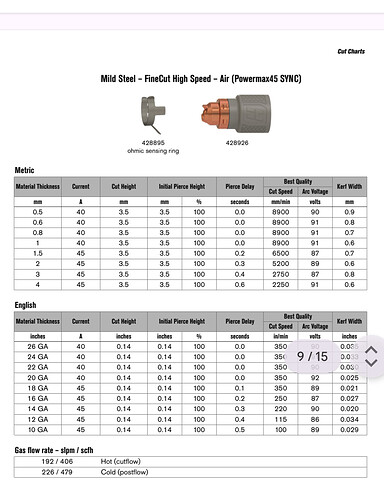

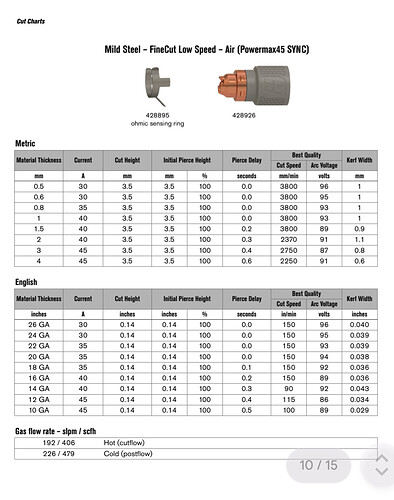

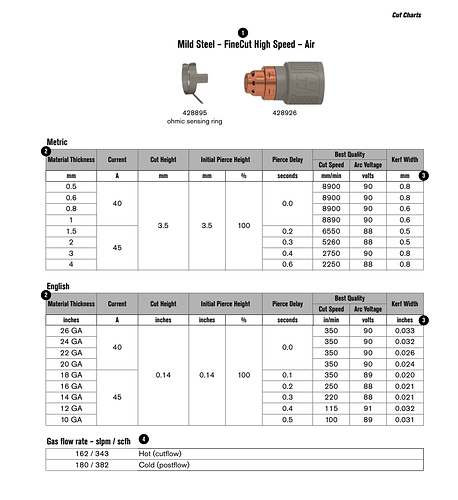

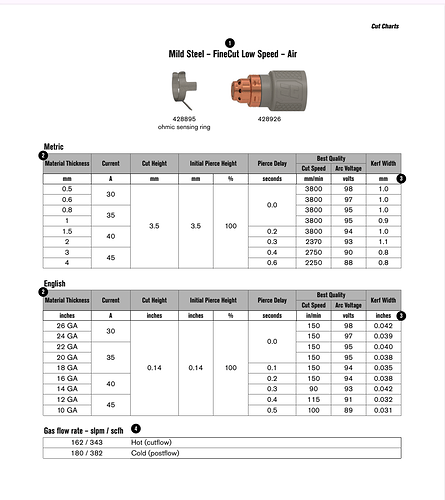

The cut charts are basically identical for the 45 amp consumables whether it’s being ran by the 45 sync or the 65 sync.

PowerMax_SYNC_Cut_Charts.pdf https://share.google/DUE2fER59yLOJbwIj

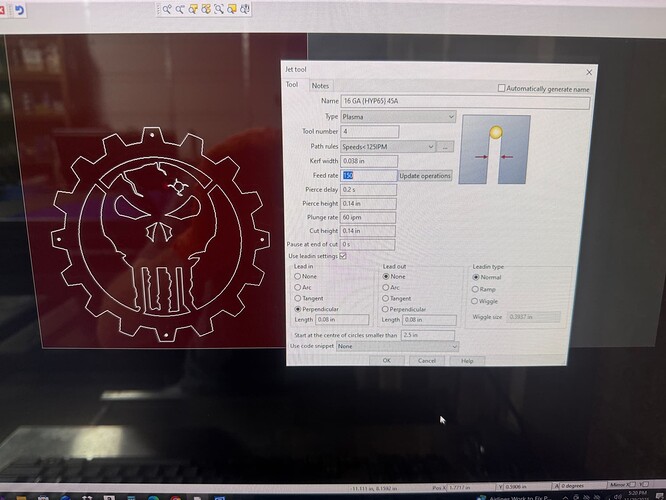

The cut height and the pierce height are both 0.14

I have around 500 Pierce’s total. I’ve ran 45 amp and 65 amp cartridges on my machine so I don’t have an accurate count for the fine cut

I’ll re-program my part with those settings and see what happens. Set it to the book I could say for testing. I’ve read from so many ppl here than cut height of .060” worked well, so that’s what I had set the settings to

0.12 to 0.14” is the norm for a Sync setup.

The 0.06” is what other plasma cutters call for, including the non-Sync Hypertherm machines.

It’s a pretty common cut height. But the hypertherm sink and thermal dynamics brand plasma cutters usually have a higher height.

It is always best to start with your manufacturer cut charts as a datum and then start tweaking it for your personal setup from there.

Hypertherm spent a lot of time and effort populating that cut chart. It’s a good start.

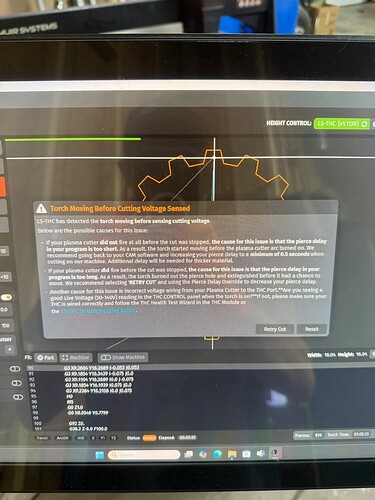

So I re-ran the 2 programs at factory settings for 16ga steel per the book. And it ran….. the o my hiccup was it stopped mid cut and gave me an error code for pierce delay time, restarted and it finished the part. However these were small parts and a quick cut time.

I’ll have to look at it when I’m back at my computer so I can actually zoom in and see the g code and what’s going on. it’s too small on my phone.

What path rules have you added?

I haven’t added anything other than Speed<125IPM

(This post does not apply to the XR…sorry, got ahead of myself on this one. Tin will explain a few posts down on this thread.)

The pierce delay of 0.2 seconds might work with SYNC machines but you probably need to make it closer to 0.5 seconds.

You will know if the pierce delay is too long when it messes up your lead-in (with a larger burn mark and metal gone) or the torch flames out. Hypertherm and the FireControl calculate the pierce delay differently.

You were able to get your first piercing and contour cut because FireControl adds about 0.5 seconds to the first piercing.

I did have it set to .5 on the delay before when I was cutting other parts after that error popped up and haven’t had an issue. I did not know that FireControl adds delay time to piercing that’s good to know for the future

Yeah I was going to say, my Hypertherm on a different table cuts up to 3/16” with a 0.1s pierce delay.

But the same Hypertherm on my Langmuir required a 0.5s pierce delay minimum.

I have no experience with Sheetcam, but my 0.5 requirement was when I used Fusion 360. Anything less than that, and I’d get the same error after the first pierce.

The first pierce always has its own extended delay, and every cut afterward runs “normally” as input by the end user.