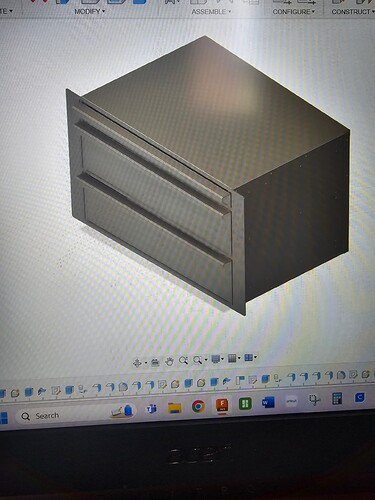

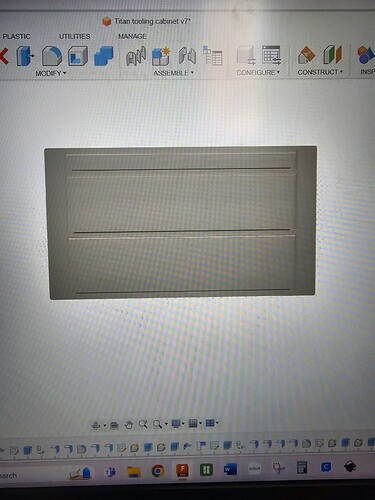

Here’s a few pictures of my tooling box build for under the Titan. Hope you enjoy!

Nice looking design and build.

I’ll bet that the bottom drawer is sucking wind holding up those dies. I had to bolt my box to the floor. If I opened the bottom drawer, it would try to tip over. I would love to copy that, but I am not up to that speed yet.

This will have to do for now.

Nope the box is screwed down to the wood base. I used large screws with big fender washers. I can open both drawers full of tools without it tipping. I don’t recommend that but lol.

What brand is your oven?

I built it myself

So on the die that is two over to the right is it hard to get a grip on it? looks like it would be hard to grab. I have all ready dropped one of the slippery lil bastards

Very nice work my man!

Very nice. Thanks for showing the complete build!

I can grab it easy. You need stronger hands lol!

Trust me pal, thats not all I need ![]()

![]()

Haha, we all need a little help these days. Doesn’t get any easier does it?

Aint that the truth… Never ever easier.

3 years ago I was bench pressing 400 lbs.

Now I struggle to pick my 30 lb toddler up. The last 3 years hit hard…

I hear ya 2019 I was running 10 miles a day. Got Lyme disease camping and now live with the pain. It’s gotten better but still not the same. Good thing for this hobby or I’d go crazy.

Knick, Super job. What spacing are the slots on the top cabinet. I plan on building mine out of wood.

Knick, A few more questions. What is the overall width at the front of your cabinet and what capacity drawer slides did you use. Hubert

As much as I’d like to take credit for that, I can’t

@custommetalmke Jake built that.

If anyone is interested I put together a package with all the dxfs for cut file and pdfs with bend prints and over view prints. Private message me if your interested and I can get you the details.

I slapped an oven together the best I could for the little time I have. 2 electric lamps in series for 240v, one lamp at 120v, plus a propane camping stove. Works great, except the durock tends to crack with the expantion from heat. It was a great thought at first cause durock can take up to 2500 degrees. I want to expand it twice the size so I can pre-warm parts wile others are curing.

What are you basing it on that it works great?

That set up can’t possibly work well

Uneven heat

Fumes and soot from open flames

No door to keep dirt out and heat in