I see a door.If it works for his needs seems it works.

I guess It all depends on what your definition of works is.

There is a door, the heat lamps are attached to it. There was no soot after the fresh air valves were adjusted to get rid of the yellow flame. Me wanting to make it bigger will get my parts out of the direct heat from the burner.

Have you powder coated before?

Well that looks pretty sweet too, well done!

been at it for a year and a half, not before that.

I would love a link to the files! That drawer setup looks really nice and is exactly what the unit needs. What CAD do you use?

Thanks! Send me a private message and I’ll give you the details. Also I use Fusion for my CAD.

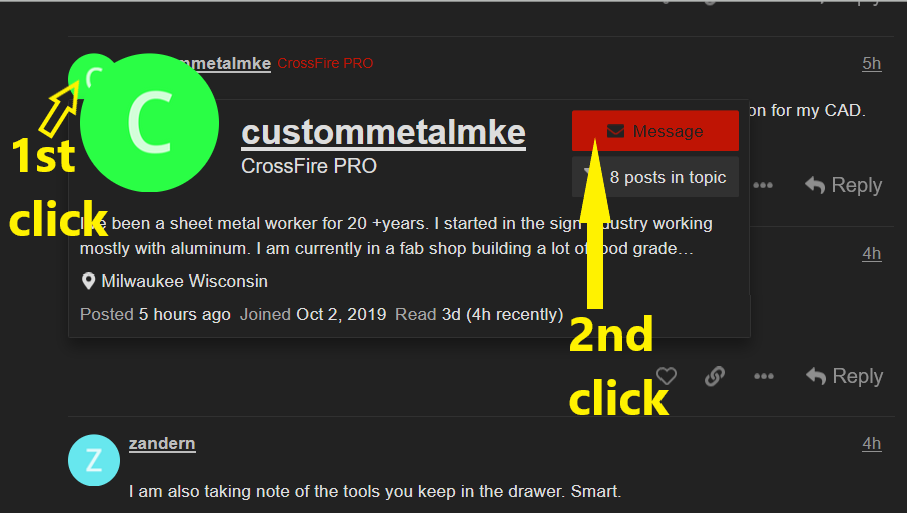

I feel like a bit of an idiot that I can’t figure out how to DM on this forum!

I am also taking note of the tools you keep in the drawer. Smart.

Click on his avatar. Pick message. There you go.

Thanks guys. Turns out i did not have enough forum cred for that button to show up. But now it’s there!

What’s the empty slot in the bottom drawer? I’m guessing a punch cuz I think I see all the available die’s.

Can you tell I’m trying to figure out my punch/die order? ( I just got my Titan is ready to ship email.)

I’m going to try and do a box like that, it looks perfect.

Hopefully i won’t put to much metal in the scrap bin. ![]()

It was an extra slot for some of my homemade tooling.

Also if you don’t want to waste metal I’m selling the cut files and pdfs for Bend prints and instructions for $50. Just throwing that out there for you.

I’ll wait till the machine gets here first, and get a sense of the things ergonomics.

But if it’s anything like what I have in my mind from all the vids and pictures, then that box would be perfect and I will probably take you up on that offer.

would you be willing to part with the design files? or share them

interested in the files for the tooling box

He sells them for $50