I like the single safety stop setup better.

Thanks for sharing. So cool. I have a lot to learn. Got a good 3D printer a few weeks ago. I think it’ll be a great partner with the 25T.

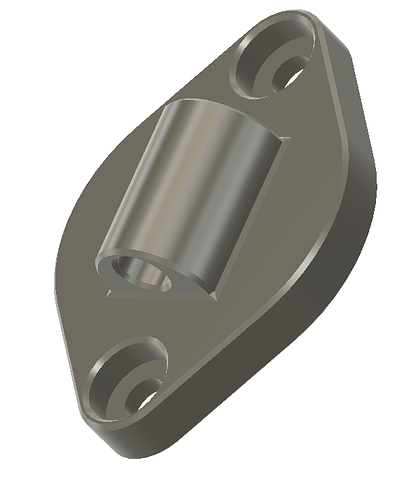

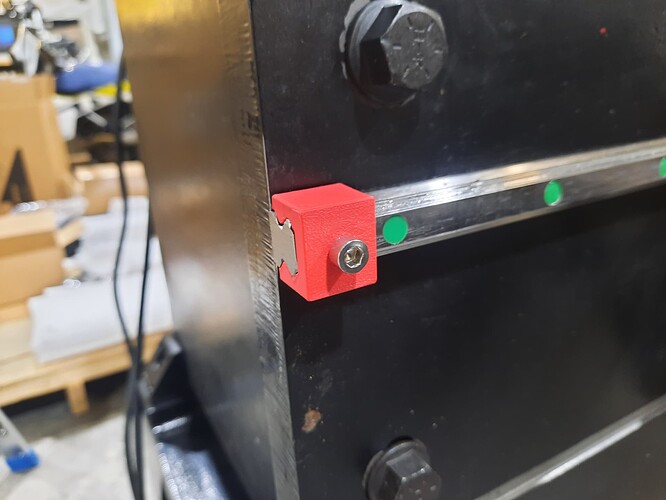

I updated my safety button mount. The right side hole cover still holds the hex wrench but now gives you USB port access.

and light curtains are way to expensive. That would price the machine out of rang for the target market.

I know the LS machines don’t have every bell and whistle but we’re getting a HELL of a deal for the $. I think sometimes people forget that part. I’m also guilty of this. I catch myself saying, “if it only had x,y or z” Then I consider the $$

well now they are cycle start buttons and not “safety buttons” haha. I do really like that Allen wrench holder.

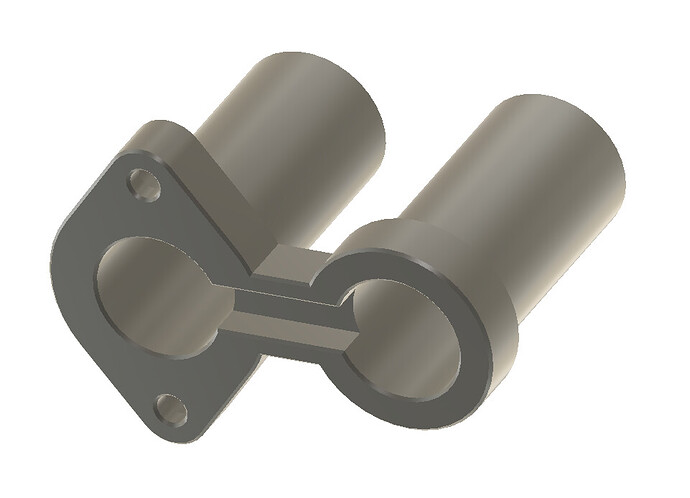

My first design had them separated on right and left, requiring both hands.

I printed both the switch bracket and the Gen 2 hole cover this morning. I’m still home sick, but my assistant says the printer finished both items very nicely. I’m feeling better, but I’m taking it easy until Monday while babysitting three chihuahuas. It’s like a kindergarten class!

That Bambu X1 has paid for itself 3 or 4 times already.

Mine has paid for diddly squat but I love it!!!

(Well ‘love’ may be a strong term…I have fun with it…now that comes out wrong as well. Delete)

Thank you, @holla2040. I have hit my head for the last time. ![]()

glad to hear it.

You need to add one of these to your Titan @ holla2040

Definitely!

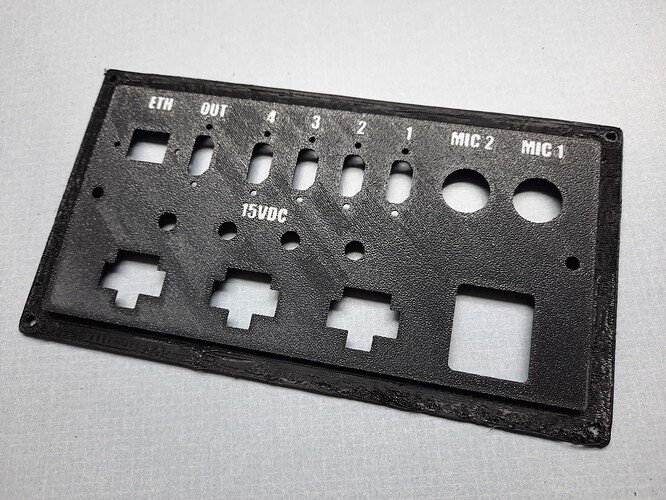

Finally got around to sorting out a storage solution for all my punches and dies thanks to my 2 Bambu Lab X1 printers putting in some long hours with 8 or so rolls of Elegoo Rapid PETG, and a couple new US General 22" rolling tool chests. I had intended to form and weld up my own super ridiculously over built rolling tool chest, but once I calculated the cost to build my own chest of drawers, the load per drawer if I organized the dies into these tooling chests, the extra storage it would afford me that would allow me to get rid of a large work desk, and the need for every single extra square inch of floor space, it didn’t make sense to spend my time competing with the Chinese when it comes to building tool chests, especially with the recent 20% off sale.

So here’s how it went…

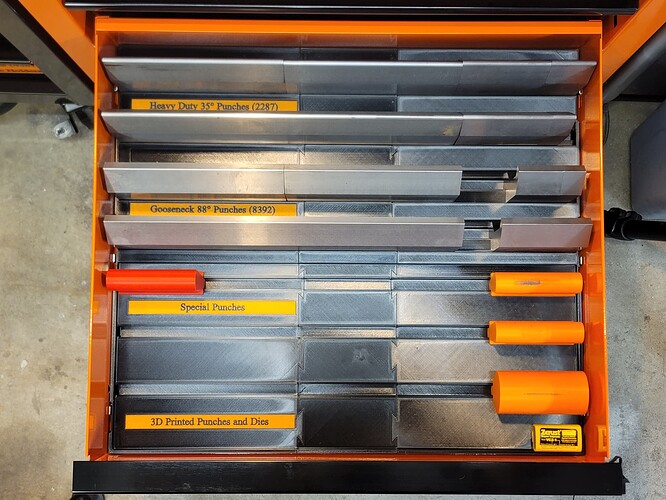

Acute and standard 30° punches, extreme 85° gooseneck punches, and space for extra 3D printed punches as I expand my collection.

Heavy duty 35° punches, gooseneck 88° punches, space for 3D printed punches and die sets.

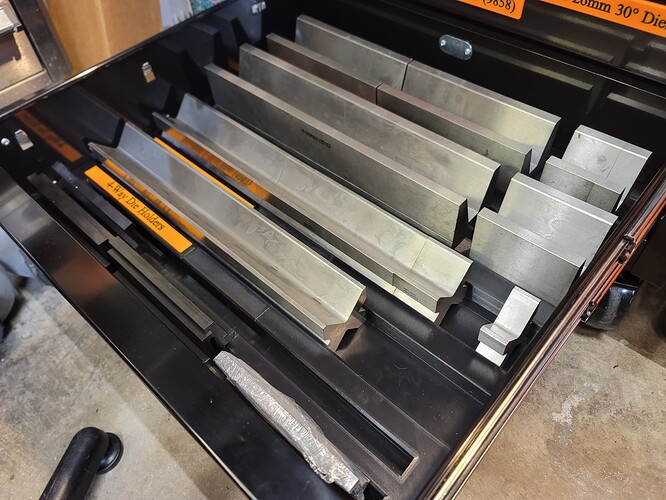

4-way dies and holders, Acute 2" dies.

Acute 30° 8mm, 16.5mm, and 26mm dies, space for special dies and 3D printed dies.

Finally a drawer labeling solution I like. Magnetic name tags that travel with items when I reorganize drawers. Those labels that they used to use on the face of the pulls on the US General boxes never worked for squat.

I may have gone to, well, maybe not extremes, but, I did print over 100 in total so far.

Just in case anyone here has one of the series 3 tool chests from Harbor Freight and needs a little punch storage, I have my first drawer test print that isn’t going to be used that I’d be willing to send to someone if they pay for shipping.

I ended up redesigning the drawers to dial in the weight per drawer better once I had a chance to test the drawer fully loaded. With the qty of punches I had loaded in the drawer I didn’t like how draggy it felt. Moving the 88° gooseneck punches to the drawer above with the HD punches and shifting the 85° extreme gooseneck dies back in the drawer balanced the weight much better. It wouldn’t probably be much of an issue, except I have 39" worth of each punch and die and that ends up too close to the 240lb weight capacity for the double slide drawers.

Call dibs in a post here. First come first served. Should be able to fit them into a large USPS flat rate box. If you can find a cheaper way to ship them that isn’t too much of a hassle for me I’m open to that too. Pickup is also welcome.

Very nice! Immaculate organization. When you use those special 3d printed punches, which dies do you usually use alongside them? Just the ones appropriate for the material thickness?

The large radius punches can be used with either the 4-way dies, the 2" V dies, or the special sauce I’m using with the 4-way die, which is what produces the cleanest result and is the easiest to make a smooth bump bend with, and is the most appropriate for cosmetic materials.