I would be interested in your CAD files for the base!

Here ya go.

TITAN 25 BASE 091124.DXF (139.3 KB)

TITAN 25 BASE 091124.pdf (27.5 KB)

TITAN 25 BASE 091124.STEP (770.7 KB)

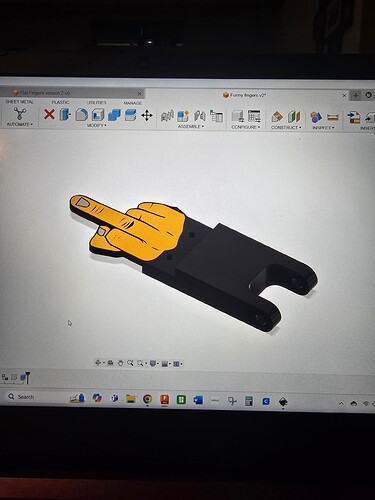

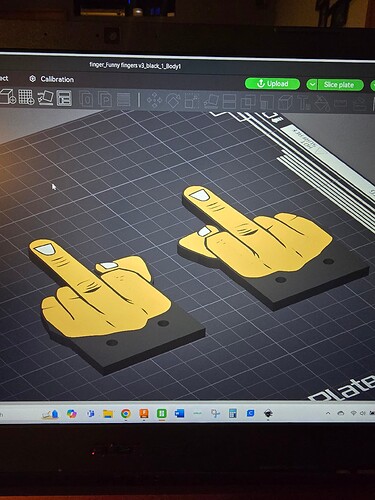

here is a step file for anybody interested in the back gauge Fingers. These were printed out of asa. After printing you will need to clean out the holes with a drill. Not sure how they will hold up long term. Processing: IMG_5338.jpg…

Titan 25T Backgauge Stop.step (43.3 KB)

Finally finished a few sets of flat backgauge fingers on the MR1 this weekend. Got them black oxided and oiled tonight. It was a fun little project that’s for sure!

Nice print. Anyway to share a file? Seems like a very easy fix for the arms in the eye.

Here is the Step file. if you need the stl file pm me and i will send it. the buttons unthread from the black pieces and thread onto the 3d printed ones. i used smaller layer height on the threads

Titan Safety Buttons_.step (504.8 KB)

Thanks super appreciate it ill check it out!

File link? Please, Thank you. I’ll print a pair up. My business partner will get a laugh.

Have you posted these files somewhere? Great idea! Just got my first printer last week!

I posted them in a step file here about 4-5 post above this one

Here is a link to the step and stl files I just made on maker world

I really like your stand design. I’m 6-4, so I want to it to be a little higher. The slots in the lower trey is a good idea, but to protect the dies from all the fab shop debris, I will go bend up 3 pull out treys with the slots you have, or maybe heavy gauge metal treys with some milled wood liners to soften the use a bit. thanks for the inspiration ![]()

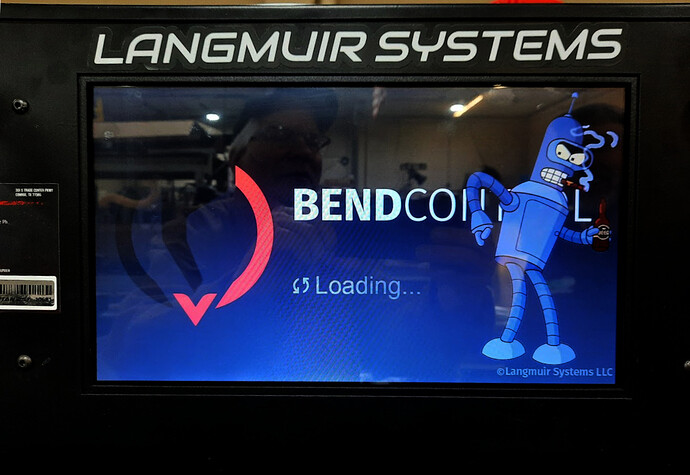

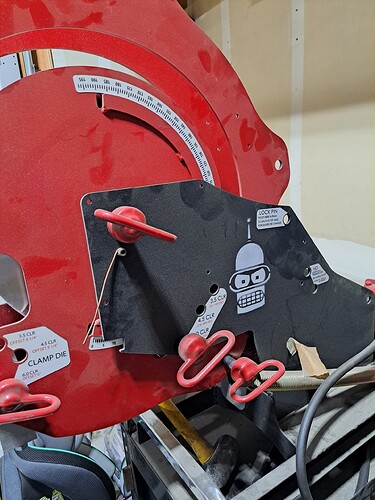

@holla2040 i need to know how you did that or rather can you do that to mine. it very much fits my brand. ![]() i love it.

i love it.

You can loosen the set screws holding the buttons on the end of the arms, then disconnect the buttons. Then just unbolt the arms and switch which is on which side, refeed the wires through, and reattach the buttons. It’s pretty easy and will make sense once you pull the top cover and buttons off.

I also am over 6ft and wanted it higher. i made up my own stand and put a HF tool box under it that holds all the tools and dies nicely

I was looking for a short rolling tool chest that I could bolt on top, but didn’t consider a top box - excellent idea! Those billet aluminum side places are very impressive!<want!

I am curious do you find yourself bumping into the tool box stand in the front? Seems like it sticks out to the point you would.

Perfect fit for the Titan screen.