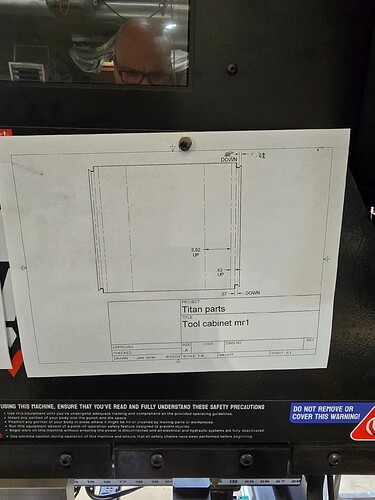

I think the 2nd bend was programed to be 135 Deg. inside. It was bend #2

I don’t know if I have the authorization to send out exact sales figures but it is a lot - email our support line at support@langmuirsystems.com and we might be able to get you a more official answer.

smiling over here. Thanks.

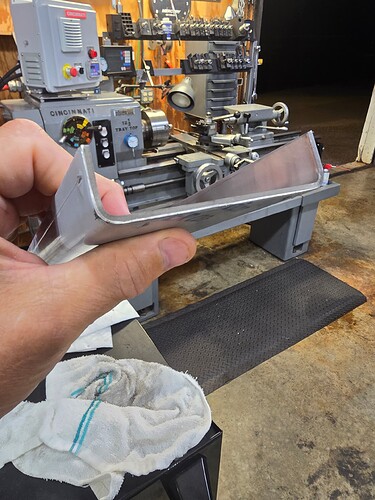

I bent this 11ga polished 316SS this morning—two full 32-inch bends. I am very pleased. The back gauge worked as expected. So far, so good on my machine. Hoping for more videos soon. Wondering about this new beta update, though?

As far as I know most of the problems are with the back gauge. if yours is working I would leave it alone.

That’s gutter talk

First time with .250 3000 series aluminum @ 90°

bend. Perfectly bent.

Outboard motor transom bracket.

This was a 14" test piece. We then bent a 24" version

that came out nice and pretty

you fancy!

More jealous here… ![]()

Happy for you guys/gals!

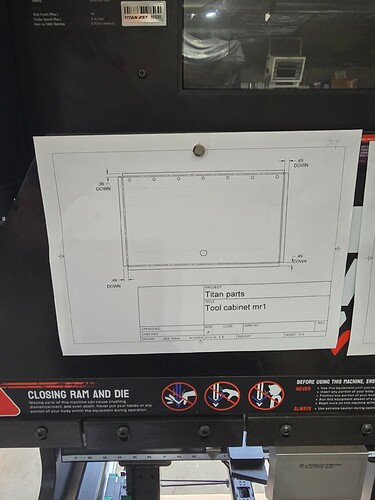

Bent up this cabinet last week. Gotta say other than the software being buggy as hell the machine works great!

Looks absolutely awesome! The bends on your base are quite complicated.

You are the new Titan 25 guru. Your work with this machine is on the next level. I have never worked with a bending CNC machine, but I bumped through it. Wow. @custommetalmke

Nice Job Jake, When are you coming by for my personalized training? ![]()

Thanks man! All in the practice!

Please send more photos or videos for us envious ones lower on the order list.

Nice work, very professional!

I will leaving wisconsin for Colorado on my Harley tomorrow for a week. Once I get back it’s on!

Are you blowing through SW Colorado, going over Red Mountain Pass?

If so, you can stop by my shop in Montrose, its on the way.

let me know and I’ll give you my phone number.

Thanks I’ll let you know. I’m riding with a few others but if we got time!