I spoke with friend that plays with this stuff and he’s buying the Bambu P1S for his next machine. He told me the Bambu A1 mini might be good starter unit.

Honestly, I am not sure what that means…not trying to argue either. 3d printing is not the most precise thing to start with and most of the “problems” are from the printer, not the slicer or the model.

And I put problems in quotes as even the flaws mostly do not matter with the current batch of printers and the part looks nice enough and are functional.

So hitting the easy button is well … easier for me and likely most folks.

I understand. STL is simple and fast. Your point about accuracy is true as well. However with layer heights of 0.08mm ( 0.003"), the mesh tessellation might become a surface quality issue.

Fusion can also export 3mf files but these are still meshes.

Steps offer superior resolution

For @TinWhisperer using Bambu Studio with X1C, the work flow is the same. Fusion exports a file (stl/3mf/step) then imports into Studio, then prints. Might as well use step files.

I used stl files for years, only recently did I learn Bambu Studio could import step files.

Print the two color badge. It blew me away with the detail.

So long story short by the end of yesterday I decided to buy a Bambu A1 mini. I don’t care about spending $500 as much as I do about $1500 to see if I even like it. To keep this forum appropriate let’s, see how to incorporate the metal cutting on our tables to plastic printing. I’ve never done anything plastic but already have my eye on making hinges in fusion.

Congrats, the experience so far has blown my mind. I don t sleep much to begin with, and even less now with this amazing idea printing machine in my office. My only regret so far is not buying this machine earlier.

Its so true. I have a all or nothing personality so I may get divorced over this…

We are on the same wavelength . I also thought about having a design “contest” that the project shall have at least one 3d printed component and one plasma cut component. Extra bonus for documenting workflow and using sheet metal bent parts.

@ds690 @djlois @holla2040 @TomWS Have a head start on us.

I already have my “entry” in mind… I planned it out last winter. It is a ski rack for our patrol snowmobile. I have been trying to find a used printer because I have the same condition you have and I don’t want to get divorced over a printer… ![]() the other option is to have my coworker print me the parts… but I REALLY want to do it myself. The other reason I have been sitting on it almost a year is I want to make it out of aluminum and I have never cut or welded aluminum before. And what I have planned requires both. I have collected a bunch of scrap to practice on so I am almost ready to design. Actually it s a good thing I haven’t made it yet because they told us at our refresher last month they are buying us a new snowmobile this year… still a skidoo so the spacing on the mounting holes for the link system should be the same, but they say it is wider. I will have to think on the printer some more.

the other option is to have my coworker print me the parts… but I REALLY want to do it myself. The other reason I have been sitting on it almost a year is I want to make it out of aluminum and I have never cut or welded aluminum before. And what I have planned requires both. I have collected a bunch of scrap to practice on so I am almost ready to design. Actually it s a good thing I haven’t made it yet because they told us at our refresher last month they are buying us a new snowmobile this year… still a skidoo so the spacing on the mounting holes for the link system should be the same, but they say it is wider. I will have to think on the printer some more.

I made some steel linQ brackets out of 16ga steel and posted them earlier in summer. Many layers but they worked great on a trailer. He could run them over without concern of messing them up with UTV.

My friend with the X1C got his mini 2 weeks ago and loves it, you will too.

I have…want me to teach you? ![]()

![]()

![]()

I actually have welded it. Requires Argon gas and I did use the shielding gas. Any attempts without shielding gas and you get a bunch of aluminum bb’s (yes, I did that too).

I started out on a ender 5 pro and have since bought two more enders.I bought a p1p because of the rave reviews and since got another and upgraded both to p1s’s and one ams unitThe Creality machines have been collecting dust and have sold one.I would buy the A1 or another p1s but im waiting for them to release a bigger machine.I absolutely love my bambulabs p1s printers.

I’ve had mine for over a year and love it. Wanting a second one and regret having missed the Black Friday sale they had.

The BL forum is a great place to get tips, tricks, and help.

I’ve done the typical toys and trinkets to replacement parts and make life easier stuff at work.

Thanks…Today I’m the new guy learning this stuff.

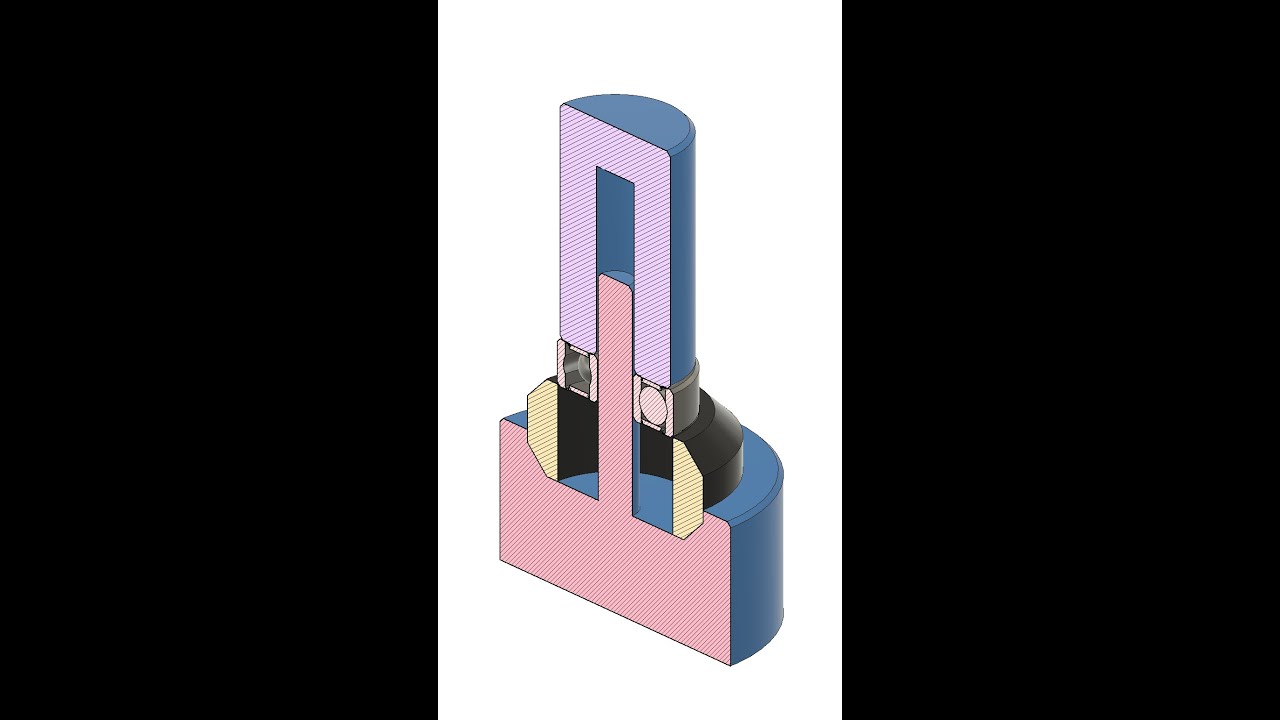

What material did you use to make the mini press jig?

So many cool ways to use the wheels…

One example -

DS690 - I had a lot of trouble in freecad with threads untill I added the fasteners workbench. Not sure if you have found this but it made it super easy to have all sorts of threads and fastener types.