My recent problem was trying to find the Y center on a tube mounted in a vise along the X axis. Boss wouldn’t work since the piece was 23" long. Would have been nice to have a boss-type function that would find the center of whichever axis you specify.

Completely agree. Have had zero issues with mine (drains excluded but fixed with the center-drain solution). I cut stainless steel daily and the machine never skips a beat. Even forgot the set my speeds and feeds for stainless today and it cut through some stainless tubing at what was crazy fast from my perspective - without skipping a beat.

Indeed, some expect $40K performance from a kit build. Although with that $40K the issues some are having, in person support is included.

I bought the crosfire pro 4 years ago, its been great, sure its not a 10K linclon or Baligh, but it does what I what for the fraction of cost, understand what your buying and the cost, set you expectations based on it, plasma verses mill, cost verses tolerances, I have a tormach 770, not supper accurate, but not a 40K hass either.

I understand what I was buying, langmuir is great product based on cost you cant beat it

Great Statement, and should not get any hate. You’re not bashing anyone. Just stating facts. Facts are good. ![]()

You get what you pay for. Goes like with everything you spend your money on. Well at least in the tool world.

Sorry my friend but I could not disagree with you more. The entire premise of this post should revolve around…I also have only 10 or 12k invested in it.

The expectation of having to spend over 2 times the cost NOT TO MENSION the pain and time of all the issues just to make this garbage can run should tell you something.

Just the major screw up on the collets should tell people what it is all about.

You can NOT expect a good machinist to have to completely rebuild this hunk and understand how to is completely unjust. I have more than one CNC and have NEVER experienced this kind of garbage…

I am glad you have had good customer service but there are several posts on here that would completely disagree with you. I have zero issue with their kindness and willing to help “if you can get them to call”

Don’t forget I ordered 2 machines at the same time and have had issues, serious issues with these machines and quite honestly some of this could have been avoided if not for the completely cheap garbage they have decided to build with.

You cannot honestly say that installing a .50cent limit switch on such an important process that it is, is just not OK.

I have wasted hours of time and tons of money just on screwed up parts because the THC has quit working in the middle of a cut or is works on one and not the other. How about the MR losing Z Zero

out of nowhere and driving the bit into a $400 vise? Metal is not cheap right now. I have had several times when both machines were down at the same time with ZERO getting done and NO ONE TO TALK TO.

There should be serious warnings to the sale of this machine such as FOR HOBBIEST ONLY or STARTER KIT ONLY.

I will end with I work as a customer service tech for a large manufacturing company, and I would never, never let all calls go to VM and only respond if possible. Thats bad business. I would not ask anyone for more than what I am willing to give myself.

I am definitely glad you have had a good experience but it sounds like with the backlog of calls most others are not and having to add over double the cost unexpectedly in just not right.

I wont even comment on the great job they did on the drains.

Rufus, I’m so sorry you are having so much trouble. Outside of the drain repair and me shooting liquid coolant from a spray nozzle on my original micro switches. I’ve had no trouble. My machine is number 2. I use it almost everday without issues. If I can do anything to help let me know.

I did upgrade all the drivers to the high power units. Installed the Merkel limit switches . And bored a 4 inch drain in the center behind the base plate.

I wish I had the time to do what you did on the drain. Superb idea!!

Can you give me an idea what I am doing wrong on the other post I made? I would be extremely interested in another idea.

Is it possible your computer is running out of memory ? 4 mb on their mini is not a lot with windows 11 running and god knows what else in the background.

No that one I am positive on. I bought 3 new mini’s with 228g memory only 33 used & 8g ram with .2 used and I only use what ever specific program for each machine plus I do not use internet except to update. I suppose it could be the mini but if you have followed some of my posts I have had this issue on and off for a long time. I honestly think its a glitch in their program but I cannot pin it down. It is very frustrating. I make sure change the bit before anything else because I have had so many issues.

Are your mini intel chipped or Ryzen?

The Ryzen chipped mini have been having some issues with windows. Not 100% sure.

I think intel but I have to double check that one

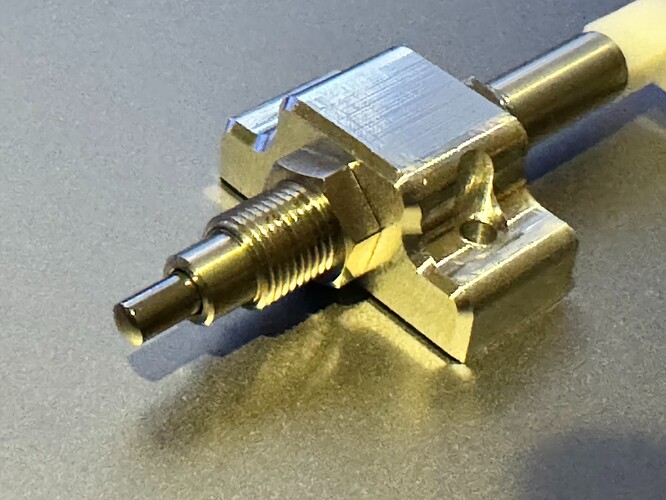

Can you send me a picture of their merkel limit switches? Curious what I received this last summer. Thanks!

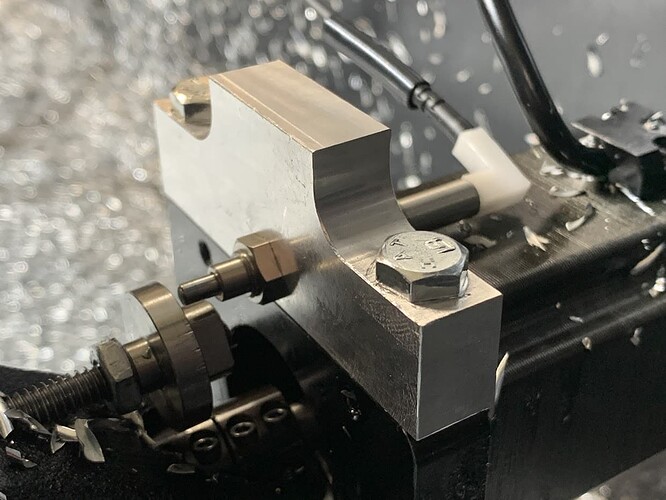

My machine is in my shop at work. I will be at a Marina electrical conference till Monday. Here is a perfect example of a properly installed Merkel switch that a friend of mine posted.

Thanks for the picture. Is there a reason for the raised center section, or could it have been made out of lower profile stock?

I’m still running the original limit switches without issue, but will put the upgrade on my list of projects to do.

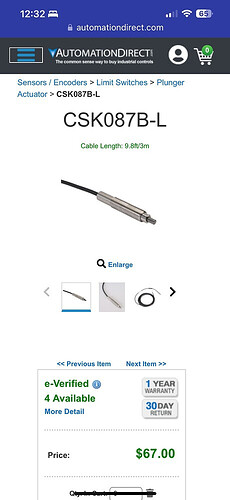

Thanks for sharing. That’s definitely not the switch I have that came with the kit. McMaster Carr?? If you have a model number let me know and I’ll buy those. Thanks again! Have fun at the conference.

Mark

The picture is a friends machine but, mine are almost identical. No reason for the raised section. Just looks ![]() I will say that I have not had a single limit switch related issue since.

I will say that I have not had a single limit switch related issue since.

I kept my mounts smaller to mount to the original holes, but they are working perfectly. I actually like the right angle version shown here. Highly recommend.

Same here. I switched (a little pun there) over to the CSK087B-RL and haven’t had any problems with squareness or the machine repeating work coordinates. 100% recommend the upgrade.

The RL switch just has a right angle lead coming out of the back instead of straight. The straights were out of stock when I ordered mine ![]()