I’ve read a few of the threads and tried the recommendations… new usb cable with ferrite chokes on each end and switched computers (Dell Optiplex 3070 to HP laptop). I’m at a loss.

A quick backstory. I have a Crossfire Pro with Primeweld Cut60. Everything worked fine last fall. I took a few months off and during that time I had a fatal crash on my old pc (lost everything on the pc). I brought the Optiplex from work and downloaded sheetcam and fire control. Fired it up and it will cut for a few seconds before it disconnects. I changed the USB cord (16 ft) that was mentioned in a previous post and I have the same issue. I updated the firmware on firecontrol and THC and also updated the THC driver. I’m at a loss and frustrated. Does anyone have any other suggestions? I appreciate your time! Gary

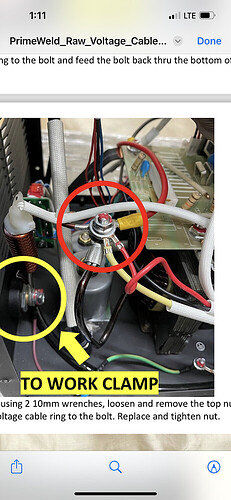

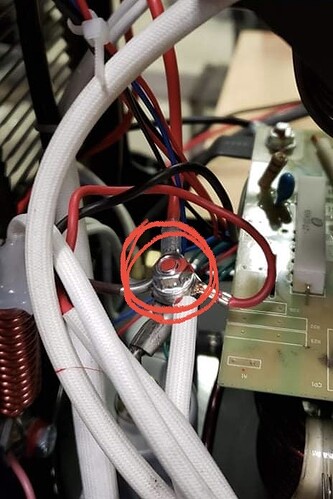

Raw voltage on that prime weld is 60. The internal board on that unit is a disaster.

USB bulletproof adapter will eliminate ground loops and take control of the weak 5 v USB signal

from your laptop. Watch the video on the adapter on Ebay.

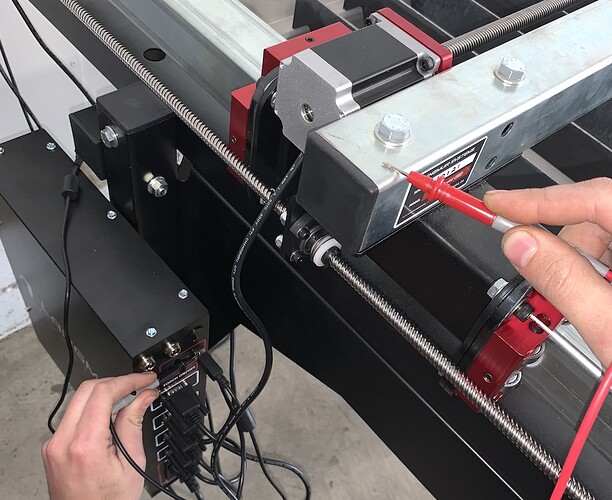

Good advice from @Bigdaddy2166 , but also check the USB connector housing on the Crossfire enclosure. This sometimes slips so the USB shell contacts the enclosure case and that really creates a mess! Try to slip some thin insulating strips between the shell and the case.

I purchased the isolator so we’ll see how it goes. The crazy thing is my old computer worked great but my new pc & my laptop are having issues. Thanks for the tip!

When your refer to the USB shell contacting the case do you mean on the interior or exterior where the USB plugs in? Thanks for the tip!

The Metal Enclosure housing the CrossFire electronics. The USB connector should NOT touch this at all.

It creates a ground loop when it touches the control box housing.

The USB bullet will supplement the power-saving features that new computers have by supplying five volts to the USB. It amplifies the USB signal so the FireControl board gets the full voltage. The old computer worked because it did not have the power saver option.

Here is mine mounted on the back of my monitor.

Thank you for taking the time to explain it. That makes sense. My isolator should be here within a week. I’ll also look at the USB connection in the housing.

Side note…If I run the job in “dry run” it works perfectly. Does that still point to the USB interference/connection issue? Thanks

There is no torch voltage involved. This problem could have 20 different causes. The USB unit is a worthwhile investment. Ensure that your table passes the ohms test.

The interference is caused by the cutter. that’s why everything works fine when doing a dry run and goes crazy when the cutter starts.

how close is the cutter to the control box? try moving it as far away from each other as possible. Also, don’t have the work clamp touching any other cable, especially the USB cable.

The cutter is about 3 ft from the electronic box. I’m not able to move the cutter because the cable from the back won’t reach the box. (see pics). The cable I’m referencing is the top left one in the 1st pic. It’s worked in the same location since I purchased the machine. Do you have any idea of what could have changed to make it cause interference now? Thanks

I’ve been using a 10-15 foot usb cable since I’ve had the 1st batch Pro and the cut60 with no issues for the past 5 years now up until last week. I got that same problem where it would intermittently freeze mid cut with torch on. My cutter has always been on the outside of the table, opposite of the control box using extensions for the torch on/off and THC.

I used another usb cable and the issue went away. IDK how a usb cable could “go bad”, but switching it fixed it. I was gonna do some more troubleshooting with the old one to see what went wrong with it.

will be interesting to see if the isolator fixes the issue for you. might just have to buy one for insurance.

I purchases a 16 ft usb cable with ferrite chokes. & it didn’t work. Hopefully I’ll receive the isolator Monday. I’ll let you know if it works. My pc that crashed was within 6 ft of the table & cutter. No issues. Do you know if Langmuir sells a 10 ft (or longer) output voltage cable? I couldn’t find one in their web store. Thanks Gary

Are you talking about the torch on/off and THC cables?

I use these extensions to extend them.

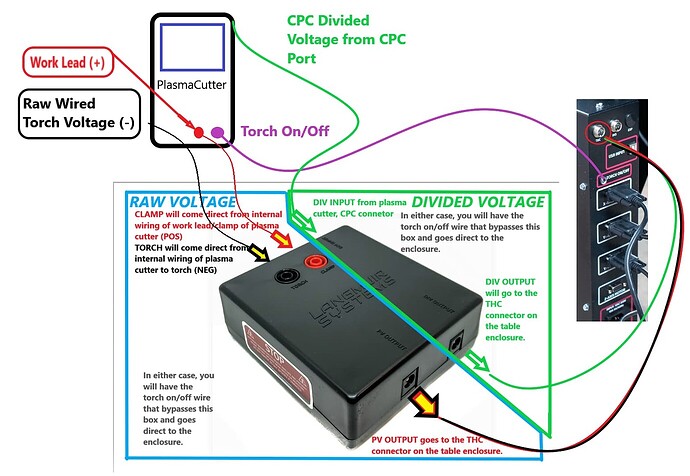

I see a Primeweld machine using divided voltage. They are notorious for having issues with the voltage divider. They usually work ok for a while, but a component gets fried over time and causes issues.

I would switch to raw voltage from inside the machine, not through the CNC port.

I’ll try anything at this point. Forgive my ignorance but is there a step by step guide on langmuir’s website? Thanks

I’m referring to the cables that come from the back of the cutter, through the DIV box (input & output) and goes to the electronic box on the table. Will the cable you gave the link to work? Thanks Gary

There is not a step by step guide for the Primeweld on the Langmuir site. I’m sure someone has posted pictures on the forum, since many people have had to switch from divided to raw voltage on those machines.