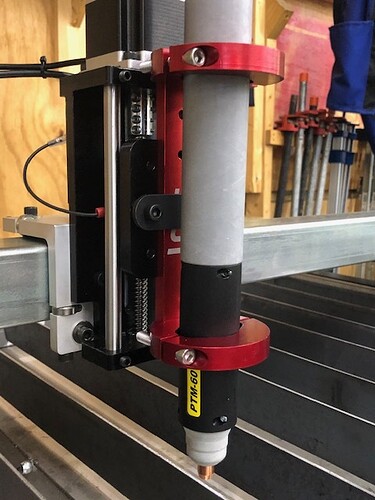

Here’s what I did for my wiring of the THC module red & black banana wires for the Early Razorcut45 plasma cutter WITHOUT the CNC plug.

Here’s what I did for my wiring of the THC module red & black banana wires for the Early Razorcut45 plasma cutter WITHOUT the CNC plug.

I will Stress if your not comfortable with electronics or electrical to seek assistance from a professional or someone familiar with electrical wiring!

I have a 20 + year backround in Automotive technology and I taught advance electronics and technology.

This is basics wiring but these lines are very HIGH VOLTAGE wires!

This is a representation of how I wired mine.

To get it to work properly for me!

On my RAZORCUT45 , early machine , without the CNC Ports.

If your have any doubts you should seek professional assistance!!

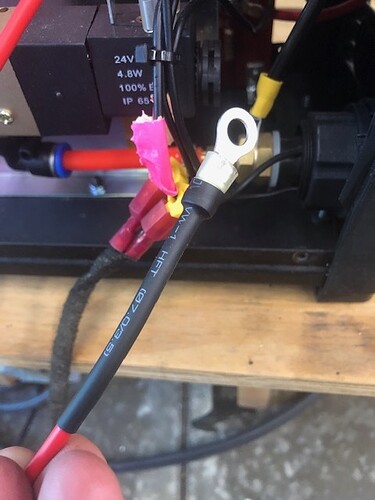

I used 600V shrink tube. Heavy duty 10-12 Ga. circle ![]() ring connectors crimped onto the red & Black pig tails from the THC Module.-(Banana plugs wires)

ring connectors crimped onto the red & Black pig tails from the THC Module.-(Banana plugs wires)

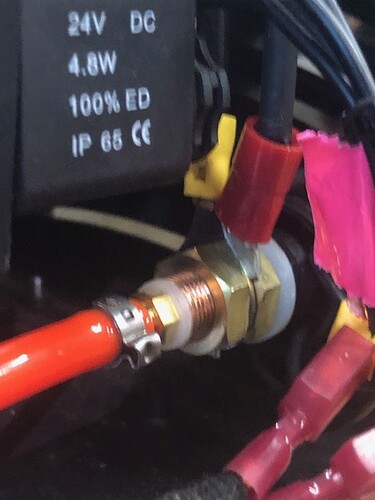

Red lead to the ground /Clamp…stud. Inside your machine.( This machine is the original RAZOR CUT 45 1st offering from Langmuir without CNC Ports) the small nut was 9mm

Inside & the bolt is an Allen bolt accessible through the front of the ground clamp port with the barrel end removed . Think it was 5mm Allen wrench that fit . The 9mm nut is really tight! So holding from the outside with the Allen was necessary to loosen it.

Black to the black torch stud which is a large 5/8” + O-ring Terminal that’s on your Torch stud inside the machine , this one has your air supply fittings on it as well. The nut was an 18mm .

Ran both out the front slots in the Face of the PLASMA CUTTER

![]()

![]()