Hello all,

I’ve been troubleshooting the poor life span of my consumables. I was setting my pierce and cut distances too close to the plates. I also identified that i have water in my air, so ill be upgrading my filtration system.

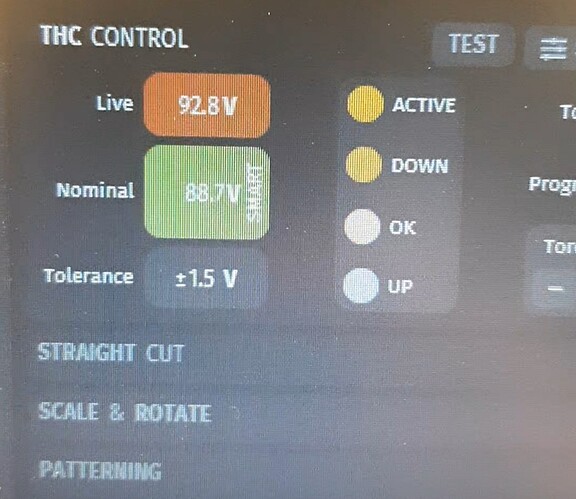

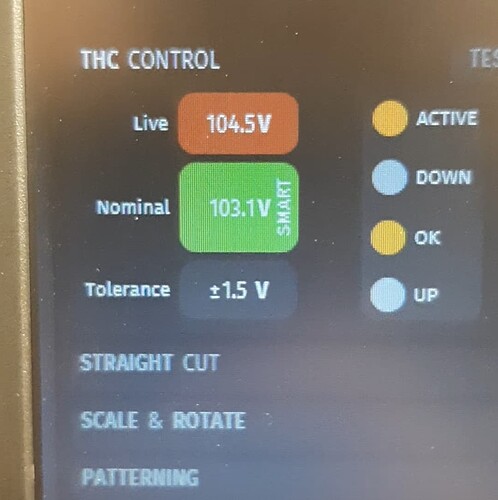

With all this said, i also noticed that my voltage on my thc is fluctuating from cut to cut within the same file. I just want to make sure its operating properly too. Any feedback is greatly appreciated!

It would be helpful to have more information. Some of this information is not directly related to your question but might help us understand how to direct you. Since you have not posted much at all on the forum, you may not have the ability to attach a photo yet. The more you post, that feature will become available.

In your example, what type and thickness of metal were you trying to cut? Was the work lead attached to your work piece? What plasma cutter are you using?

Additionally:

• CAD program used

• CAM program used (SheetCAM or Fusion 360)

• copy of the gcode of your test file

• photo of how your torch is mounted

• photos of your consumables

• Are you using OEM consumables?

• What is the brand of the consumables (not the machine they are labeled for)

• air quality and quantity (pressure gauge at the plasma cutter), what methods of drying employed

• Have you had any successful cuts with the current setup and metal type/thickness?

• Can you fire the torch manually thru FireControl?

• Is there any connection issues with the IHS contacts in the z-axis carriage?

• Have you lubricated the lead screws?

• Are you using a laptop and is it plugged in or running on battery only?

• Cut height: have you measured what your cut height actually is when you set it at 0.06 inches

2 Likes