I was able to save one of them i like Tom’s suggestions of logging functionality it makes sense. Have a great weekend

OBS can do that. obsproject.com

It’s open source video broadcasting & recording software. You can have it record what’s being displayed on your screen.

Thanks for the info i will that

I forgot to ask you if you reviewed the gcode of the file to see if I did something wrong

Thank you Tim

Thank you James that works great I installed the program and then used it tonight to record the Fire Control while it ran. It worked very well I will be doing this for a while to help with possible diagnosis.

Thanks again

i noticed that my torch will raise during cut when the voltage drops below set voltage. it will raise up along with the voltage and sounds awful haha. how do i fix this problem?

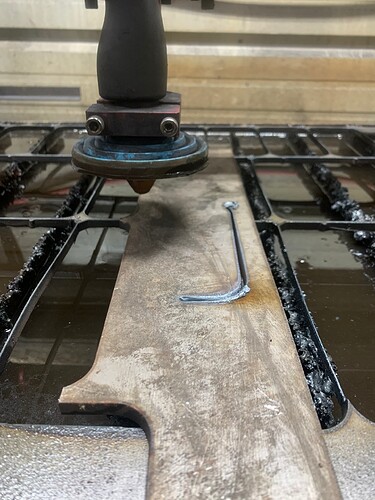

Anyone ever figure out what causes this? Mine just randomly started this yesterday morning. I dropped a ~120lb piece of 1/4” plate off my table, which happened to land on the torch whip on the floor. First couple cuts ram fine, then it started the climbing deal, although not every cut. Thought it was consumables, changed them, didn’t fix. Figured maybe it was the jack and Dave nozzles, put Hypertherm nozzle on and still did it. Ended up turning the THC off, but then had to babysit it for all 40 some pieces because it wanted to misfire every couple parts(pretty much never misfires with cheap nozzles, always seems to have misfires and bad kerf angles with genuine Hypertherm nozzles). Then I found a bug of some sort that got into the machine plug across 2 pins and got crushed when I plugged it in. Thought maybe that was the issue(although the machine has NEVER done this before, quite a few hundred hours of cutting on this machine and torch, 3rd table it’s been on and torch hasn’t been unplugged in weeks). Ran a test cut with 2 more parts I was cutting, first part it comes down, touches, raises to pierce height, Pierce’s, doesn’t drop to cut height, starts moving and then begins to climb until it’s 1-1/2”above the part and machine stops. Then the second part ran just as it should. Maybe I need to uninstall and reinstall firecontrol and THC software.

Only other thing I could think it was, was when I dropped the plate on the lead. So I cut the casing where the strike mark was and while nothing is cut inside, the one white wire has and ever so slight kink in it. Need to trace wires and ohm check them, but I don’t thing the wires are broken, since none of the insulation is cut/broken, just a little bow in it. If it’s that sensitive to voltage and the way I suck at soldering wiring, splicing in a new section of wire would cause more issues. The casing is really stout and the wiring inside seems really well protected, hoping this isn’t the issue, because I really don’t want to buy another torch.

Maybe @jimcolt has some input. I’m only about an hour away from you now too Jim, Along with beer in the shop fridge!

Maybe @mechanic416 has an opinion.

What plasma cutter do you have. You need to check the air line were the plate fell on it, it may be kinked.

Powermax 45xp. It’s not air related, it’s something electrical/software related. With the THC off, it cuts just fine. THC on, begins cutting and the x axis just slowly keeps raising until the arc is broken and the pilot arc goes out.

Do you have a good clean spot for ground lead?

As @MechanicJon has said make sure your work clamp is on a good clean spot on the metal, not on the table or slats.

THC works of a voltage reading so you must have a good complete circuit between the negative torch and the positive work clamp.

Ground clamp has always been clamped on a bracket welded to the water pan, over a year now, never an issue.

After the problem started in the first part in the last run of parts and continued on for the test pieces in the pictures, ground was directly on the plate.

The white wires in the torch cable are the main power wires, there should be at least 4 of them for the 45xp. I don’t think it cut them as the casing was not damaged from what I could see in the picture but you need to check them all.

If this didn’t start to happen till after you dropped the plate, something some were has come loose in the wiring I would think. Did the plate hit the table and move it maybe causing it.

the drop may not have cut the wire…BUT…when you compress the insulation around the wires you reduce the insulating effectiveness…

you may be dealing with leakage or electrical interference…and we all know how sensitive voltage readings are.

Are you able to try a different torch to see if the problem persists?

That’s kind of where I’m at. Yes, I have another hand torch I can swap the pin in and try out on the table.

Going to reinstall the software first.

However being that this has NEVER happened before dropping that plate in the whip, and it being a problem on the first part and all consumables have been ruled out, it’s something in the torch wiring.

Good excuse to finally just buy a damn machine torch.

Downloaded the newest firecontrol and redownloaded the THC driver for Mac, same shit. Cut a bunch of small circles in 1/8” and kept an eye on the THC voltage, it stayed right where it needed to, so I went agead and setup a quick run of 1/4” parts. Makes a few small cuts then gets to a long cut and halfway around the part, the THC voltage just takes off and torch climbs during cut. I stopped it before it got out of hand and ruined another part.

Turned off the THC and just let the IHS set the height. Misfired a few more times with the genuine Hypertherm nozzle, switched back to the jack and dick nozzle from amazon and it ran the rest of these parts flawlessly. That’s all good and well for 1/4”, but this is really annoying having to babysit the machine and knowing that I can’t cut thinner material. It’s clearly something in the whip, because once the wires warm up a little, it acts up. And the evening before this started, it cut parts for almost 2 hours, non-stop, trouble free.

Going to post in a few spacebook groups first, but I have a machine torch in my cart with Bakers, think that’s my fix. Just be more careful in routing my torch lead.