I’m Really hoping someone who has experienced this can solve my issue.

I just finished cutting two separate programs that were 50 minutes each (big tree silhouette) both were completed without errors of any kind. the next program I start cutting out some simple square tabs and they are all messed up. I noticed the torch head is driving into the material and dragging real bad. I had to go back and re set all the bearings, cleaned everything and the whole assembly is back to normal but the issue persists. I assumed a ground issue and found my ground clamp was very corroded so I did a complete disassembly, cleaned and put it back together, put in new consumables and ran another program and while the symptoms have improved the problem persists.

I put on a welding mask to watch it closely during a cut program and the head moves up and down constantly as if its constantly hunting for the right torch height and eventually is just drops till it hit the material. this up and down movement is not enough to see without a mask but it is obvious when observing through a welding mask. this hunting issue is not normal. I have watched cutting like this while doing the trees and the function and torch height was very smooth.

I checked my IHS and the switch on the z axis seems to be functioning appropriately. if I push up on the torch the connection breaks and the IHS light comes on. the z axis seems to be moving freely. I tested the THC and it passes and gave a reading of 141 which it says is in the normal range. all the setting are at factory settings and I have never touched them ever.

For reference i am using the Razorweld cut 45

thanks

Hello @Ammocan,

Is this occurring between multiple types/thickness of materials? Also, what material are you cutting? For thinner materials, you may need to set the nominal voltage manually.

I am cutting 11ga. its the same material I just finished cutting the trees out of.

I know you are not new to this but is there anything that pops out looking at the gcode file?

And no change that would cause any EMI issues?

- Laptop plugged in with ground plug

- Any change with how the cables run (USB to enclosure, THC from VIM, work lead, torch cable. Any of them touching any of the others?

- Check the cables for any loose contacts with the connectors (perhaps dirt/oil/silicone affecting conductivity)

- Any cables that might have received damage

I recently changed computers and found that it drastically changed where the table set the cut height. I now need to post process with totally different settings. I noticed it because the torch was hitting the metal during cuts and rapids.

Just throwing some ideas out there. I feel for you.

1 Like

new symptom not sure if it’s related.

i was cutting some lettering. i felt like i was making progress as i was able to cut out many letters. then the the torch raised up and was trying to cut from 3/4" off the material then on the next letter it would not cut at all and stopped. what’s weird is fire control didn’t throw me an error and it appeared that it thought it was still running.

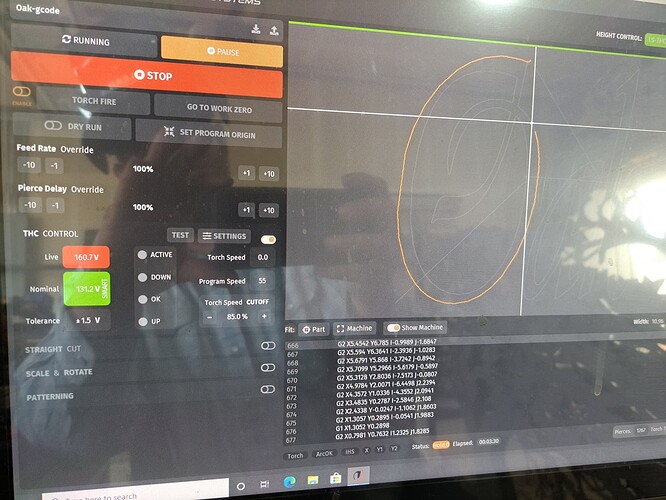

i included a picture of what the cutting looked like and the computer screen when it happened.

jim, i went through everything, every cord, connection, turned off every other thing that could possibly cause interference, even got rid of a Bluetooth mouse i started recently because i don’t know what will cause this issue.

the issue literally appeared between finishing one job and seeing up the next job. i do not think it is a g code issue because one letter will get screwed up and the next time i run the program its a different letter that gets screwed up.

Agreed.

I am glad @langmuir-alex is involved on this topic because I think we need them. You know you will figure it out but it will be the last thing you do, not the first.

I believe Bret talked about having a recurrent thing with FireControl where he would lose control (FireControl seemed to stop listening/running) but the plasma cutter continued.

In the photo, you are running Smart Voltage set and it is aiming for 131.2? and the Live voltage is 160.7? Is that correct?

Some things to try:

-

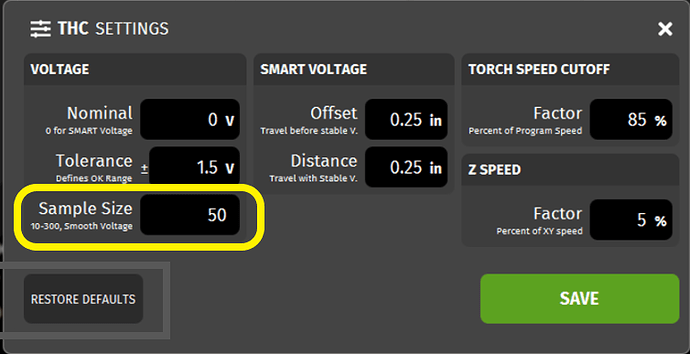

Increase the sample size in the THC settings. This will give it a longer time to think about things and potentially allow the plasma cutter or FireControl time to throw an error.

-

Try running with THC off. If you lose control of FireControl during those times then you know it isn’t something to do with the THC module (maybe?).

-

Try running with nominal voltage. I would guess if you don’t know what the voltage would be, I would probably plug in the 131 volt since that is what the THC was trying to hit.

1 Like

If the consumables are new/good and cut height is good .Check your ground cable. Is the twisted in and locked tight. Is the ground attached to the clamp and the twist connector tight and proper.

2 Likes

i have tried the ground clamp in two separate ways with the same result. i completely rebuilt my original ground clamp to eliminate all the corrosion and that didn’t work. i tried another ground clamp that i had just built bran new for a welder and that didn’t work either. i can say with a high level of certainty that the ground is good and properly connected.

1 Like

the main problem is diagnosed. it was the limit switches. for any future reader please read the full explanation because the symptoms were not common as per the nonzero live voltage trouble shooting guide and i learned that not all the issues i was experiencing were related.

so i got lucky and quickly caught a glimpse of fire control and while the machine was at rest it was showing a voltage of between 60v and 150v then it went back to zero. it took me about 10 minutes of messing with the machine but i was able to replicate this so i could start narrowing down what is causing the voltage issue. i played with the IHS, limit switches, and motor cables and nothing eliminated the voltage. i played with every other cable imaginable and nothing fixed the issue. the voltage had gone back to 0v again but i knew it wasn’t fixed because every test cut i did, that little electrical gremlin showed its ugly face again and i could see the voltage go all over the place which was causing that “hunting” issue with the THC. for various reasons i had suspected the limit switches initially so i just decided to unplug the limit switch cable from the control box and run the program again. i cleared the alarm and ran my cut program and it was absolutely perfect. stable voltage error free cutting.

for @langmuir-alex these problems still remain.

1- my touch screen no longer works

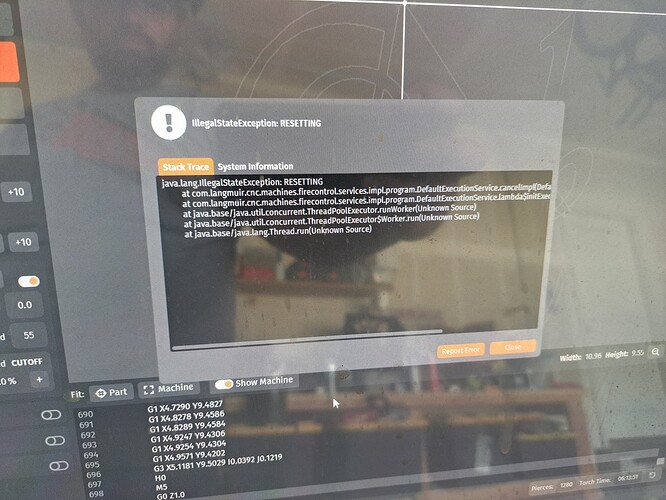

2- if i cancel a cut program or sometimes for no reason at all, fire control stops functioning all together and on two occasions it thought the cut program was still running. occasionally i get this error to pop up

3- what are my options for limit switches? warranty?

thanks everyone for your input.

3 Likes

John @Bigdaddy2166, I can’t believe you didn’t catch this!

@Ammocan I am glad you didn’t give up.

1 Like

I been busy the last couple of days. I still hate the the whole plasma table limit switch thing. I am glad he got it fixed.

1 Like

His table still has issues that he is working thru but he caught a break, at least.

sounds like you have strong opinions on limit switches. i have also recently developed strong opinions towards limit switches. what is the answer? alternatives? upgrades? switch delete? start a non profit organization to support people like me who lost 120 bucks in materials diagnosing this stupid problem?

i would like to do a fix where i don’t deal with this again. thanks for any input.

Go to the FireControl screen on the upper right and turn them off. Problem solved. The table will work perfectly without them.

2 Likes

I have had my table for 5 years and have never crashed my carriages into the stops that was not self inflected.

Dang it. I was going to post the other day to tell you to check the live voltage box while the machine was idle.

Previously we have only heard of having resting voltage there from a dirty z axis which shouldn’t happen on the XR because it’s not exposed.

I wonder how the limit switches were causing this.

If you turn off the limit switches would you lose the auto-squaring feature on the XR?

1 Like

the interesting thing about that is most of the time the live voltage was showing 0. I only noticed it one time by chance then it took me 10 minutes to replicate it. i had a 100% failure rate on my cut programs but it rarely showed any voltage above 0 while at rest. it’s was frustrating.

Helo @Ammocan. I’ve attached a few things below to look out for on the touchscreen!

- Have you unplugged the USB’s and tried using them in different ports or monitoring the connection is secured within the port themselves? The touchscreen utilizes a USB connection for touchscreen functionality.

As for the other issues, could you submit a support ticket for these issues at while I dive deeper into what could be causing this outside of EMI or basic uninstall/reinstall of the software? Thanks!

1 Like