Looking at the f360 post file - putting the delay a little earlier in the function would do what you want. The section you want has a comment “BEFORE M3” on line 387.

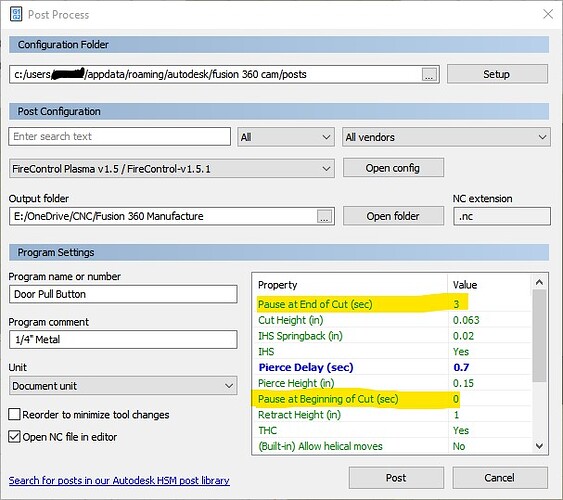

Here’s my updated 1.5.1 F360 post file. It has a pre and post delay property defined and you can set them how you like (or set them to zero to turn it off).

(Remove the .tap extension)

FireControl-v1.5.1.cps.tap (19.1 KB)

As always - this is not supported by LS, and I don’t yet know if this is the best way to do this, but it will work. When they come out with a new post (i.e. 1.6) then you’ll have to move the changes forward if they are still relevant.