I went from 120v to 220v for my plasma cutter, and I started finding tail after some of the cuts, as if the torch moves away still fired, has any body experienced this before, and what do you recommend?

Let me guess. Titanium 45 plasma cutter?

And no lead out in the program?

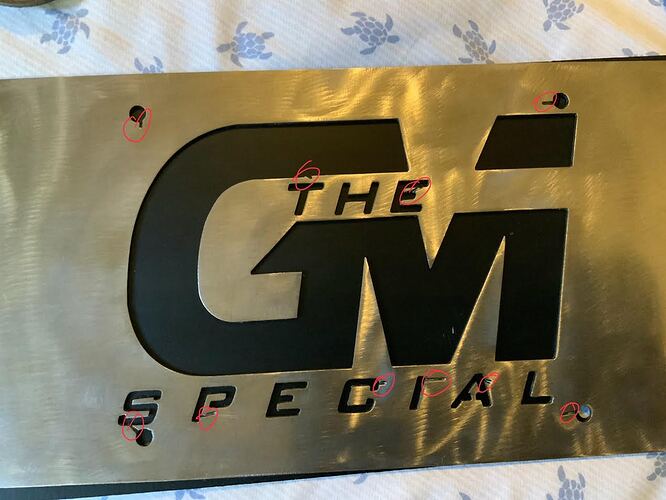

sounds like the problem is the machine, that’s exactly what I have ![]() is there a solution for this problem? or am I better of getting a new machine?

is there a solution for this problem? or am I better of getting a new machine?

No, the lead out happens sporadically, I might cut the same design twice and it is different every time or I might get none.

But are you programming a lead out when you’re post processing? What are you using, fusion or sheetcam?

Fusion 360, yeah I’m keeping the laid out option on. Isn’t the lead out supposed to go to the inside of the city out?![]()

If you’ve programmed it right, Yes but that cutter is known for shutting off late. Your lead out also may be too short. We would need to see all your settings to help.

I do usually have a shot lead in/out of .062 to make sure it takes the small cuts when seeing the process

I just re-posted this same project but I changed the lead out speed from 40in/min down to 5in/min hoping this will give time for the torch to turn off before hitting the good part of the project

Can one program a slight pause at the end of each cut in fusion 360?

The only fix, that I know of, is to add a short pause after each cut loop to allow time for the torch to shut off before the rapid to the next cut. Fusion does not offer an easy way to do this. Sheetcam allows you to program a pause after each cut loop in your tool setup.

Sheetcam? I’ll try it out, do you have a link I can use? Do you use sheetcam just to post process or do you draw on it?

Is just for post processing. They have a library of basic shapes and brackets, but it’s not for design. It costs around $140 for a lifetime license.

Awesome, I’ll check it out ![]()

![]()

‘Officially’, you need SheetCam TNG. Get the latest Stable version, not the Development version.

The latest stable version is 7.0.21

If you are using a Titanium Plasma Cutter you have to add at least a 1 second pause at the end of cut. In SheetCam there is a setting . I am not sure of how in Fusion 360 but someone has likely answered on the forum. Titaniums don’t shut off immediately so without the pause , the machine starts to travel to next location with cutter still on. Lead in and Lead Out will not solve it with that those plasma cutters.