are you always zeroing out in the same spot and starting the program from there? if so, zero out from a another spot on the table and run the program again. that’ll tell you if the problem is following the program or something else.

I’ve zeroed it at two different spots on the y and both came out the same. I can’t zero it on another spot on the x as the file is the width of the table.

Can you scale it by 50 percent in fire control and move it to do a dry run?

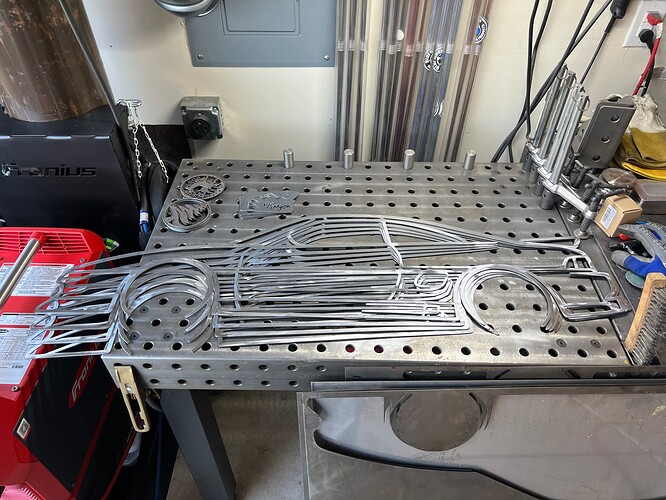

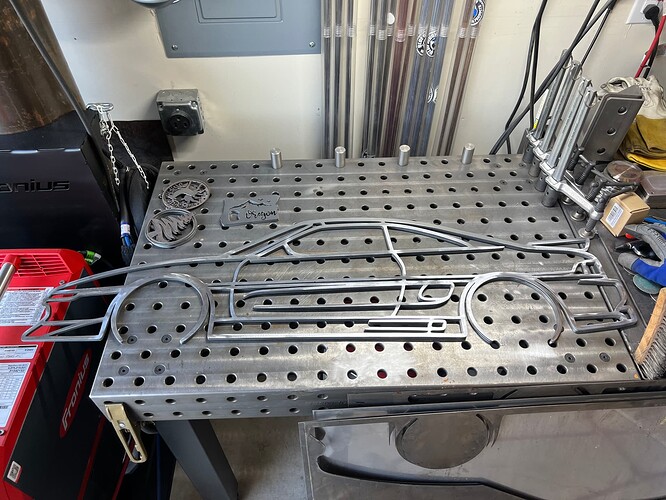

This problem seemed to have gone away on its own. I cut a few bottle openers about 4" x 5" in size in the same problem spots where it skips about a quarter inch to the left on the x on the large file. Bottle openers cut perfectly. I did a few more dry runs on the large file over the sheet with the bad cut when it skipped. In the area where it would normally skip it is now cutting to the right of it which is in the correct position is supposed to be. It appears it’s cutting correctly now but not sure why it’s working now. I didn’t do anything physically to any of the hardware. The only thing I really did was power down the system controller and removed power. I also rebooted the laptop. Powered everything back up and it all seems to be working now. I guess I won’t know for sure until I cut another of the large file but as for the dry run it appears to be cutting in the right path now. I’m waiting on a steel delivery and then I can try and cut the large file again and see what happens. Still haven’t heard anything back from Langmuir. Doesn’t seem like they want to help. Also, on their website you can’t even buy simple replacement parts. How do you get replacement parts if they don’t return your messages? I feel like later on down the road when I need simple parts like lead nuts it will be almost impossible to get. If I ever get another table it won’t be a Langmuir table. Horrible customer service.

Any chance the metal could have gotten bumped by the gantry as it went by.

Everything seems to be working now as it fixed itself.

No, because I cut it twice with the same results and all the dry runs did it too. It fixed itself now so I guess I’ll never really know what caused it.

If I scaled it to 50 percent I would not be able to watch it run over the file the was cut and I would not see it follow the bad path half way through the program.

Could have been splatter inside of leadscrew theads?? Very small hard to see.

Fingers crossed you have it fixed.

Lead screws and rails were clean. I clean and oil them regularly. Thanks for your help!