When I probe part for origin then switch to a tool, I tool set it and it places 0 at the tool/ setter height and I have to go back and set zero for the part… again. Hopping I’m just missing a step or sequence. probing it and then having to set z again kind of defeats the purpose of probing. Also… is there a setting to speed the probe up and then slow it down last .1? Waiting for the retract to move into part in slow motion is painfully slow.

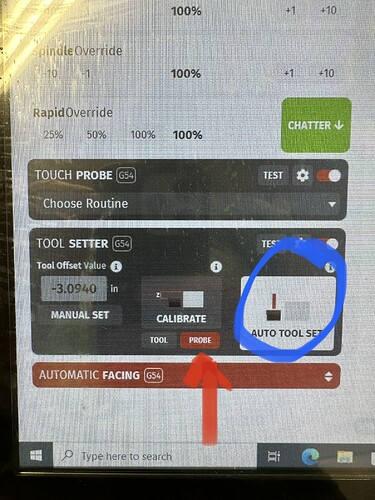

This is a common mistake. The order is touch of part with probe, make sure under calibration icon probe is select. Then hit calibration. Probe will move to touch of setter. Then swap tool and use the white “auto tool” icon to set height.

Under calibration it has “tool, or “probe” this is to tell the process if it need to look for both the setter and probe single or not just the setter in the case of using the tool for setting Z height.

Wow… thanks a million. Makes sense. I wasn’t touching the probe on setter at all. That explains the machine not knowing one end from the other. Now if I could speed up the probe up to about .1 from the part then go slow. Wish I could set the retract and speed. Not planning to touch part with speed but I know I can get within .5 and give a .1 distance prior to touching part. This probably more of a add to CC so we have more control. Thanks for the help…

One more question… Once probe checked part…then placed in probe mode in tool setter box… and probe touch off on setter. I moved machine to front… changed to tool… do I change to tool mode or stay in probe mode to go hit setter with the tool? I just tried changing to tool and placed it in tool mode, touch off on setter, then went over to part and was still off on Z at part.

I was missing the calibration part of it… just figured it out. Sorry for the plea for help. I didn’t even realized that was also a button… thought it was a logo/banner for the probe/ tool buttons. learn something every day!