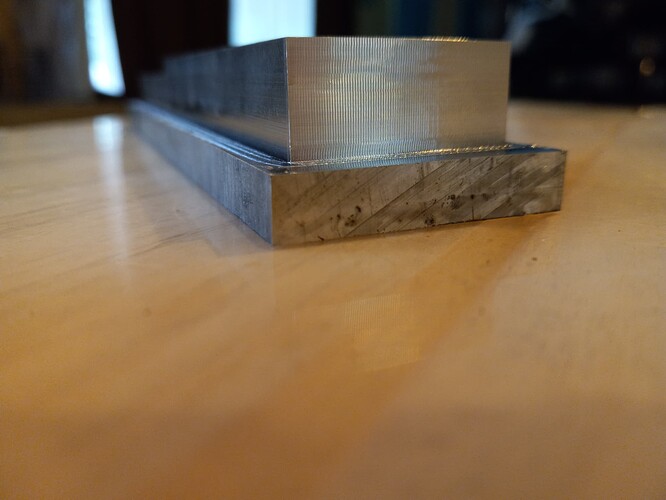

With low feed parameters, you can get a near polished surface (you can see in the picture how normal handling has put a few micro scratches into the part at random angles), but it takes a very long time and the tool is basically burnishing rather than cutting. Not great for the tool and the side wall coloring becomes uneven and takes on a “worn” look rather than “freshly machined”

What end mill are you using?

This was all done with a 2 flute Lakeshore Carbide 1/2” ZrN coated end mill into 6061 aluminum, flood coolant.

How many flutes?

edited above, sorry about that.

Have you tried a 3 or 4 flute?

I haven’t, up till this point, I’ve prioritized chip evacuation and on the bigger aluminum tools, the MR1’s rotational capacity and horsepower are well matched to a 2 flute. On the smaller tools (1/8" and smaller), I’ve considered moving to a 3 or 4 flute since the 8000RPM limits the surface speed of the tool long before the machine hits any kind of power limit.

My understanding is that I won’t see a difference in surface finish between a 2, 3, and 4 flute alone. It’s all about chip size and chip evacuation. The flute count just allows you to effectively increase the surface speed (at the same RPM) at the sacrifice of chip evacuation.

I hear ya. I like 3 flute i think there is less tool deflection & less tool presure & less vibration created compared to a 2 flute. 4 flute even more so. As you feed there is another tooth taking material away rather than pushing/ rubbing till next tooth gets there to remove material, compared to 2 flute. I always feel like the machine runs smoother. Which usually leads to better finishes. 8000 rpm spindle isn’t that high, with flood coolant i think chip welding & evacuation isn’t a big problem. I always leaned toward 3 flutes for aluminum. I like 3 flute dlc coating, ZRN also.

Im surprised in the MR1 community how 2 flute is the go too. I would think 3 flute would be the sweet spot for the MR1. 4 flute for finishing maybe. 2 flute to hog.

Just my line of thought.

Because of the lack of an ATC, the least amount of tool changes, the better.

If you can get a ‘good nuff’ finish with a 2, why the extra headache y’know.

I dont’ have any pictures, but the high speed tool paths leave a great finish both radially and axially.

Id like to see those high speed finishes