I’m getting ready to cut a sink template for a friend of mine out of 20 gauge stainless, I’ve never cut stainless so I think it’s a good idea to check with you guys if there are any particular settings etc. that are different for stainless. Also my sheet has the peel off vinyl on one side, it seems like a silly question but should I remove that before I cut? I’ve seen some people say use nitrogen for gas but that’s not an option for me, I’m stuck with shop air or possibly 100% Argon if I can figure out how to get my TIG bottle hooked up to my plasma cutter. Anyhow, thanks in advance for the feedback!

Some say for sure the gas works better than air. My understanding is cut stainless as fast as you can and closer cut height. I am pretty sure all this is in a thread somewhere. I definitely would remove the peel on it. It will probably melt and make a mess. Just there to protect the Polish finish.

I was having a heck of a time with 14 gauge stainless. The dross is not friendly at all. I was using the settings in the Hypertherm 45XP manual for standard consumables.

Then I saw a post from Tin, talking about cutting with fine-cut. I happened to have some fine-cut consumables but had never tried them. It was night and day difference. I shared my results with Tin and he agreed that the fine-cut makes all the difference. It has a cut height of 0.02 vs the 0.06 of the regular consumables. Tin also said, you don’t want stainless to get hot so he actually pours water on it even during the cut.

I asked if he uses bottled gases and he said he is just using dry compressed air.

I don’t remember what plasma cutter you use, but see if you can get fine-cut consumables. I doubt the plastic film is going to mess with the cut but would not want it on the top.

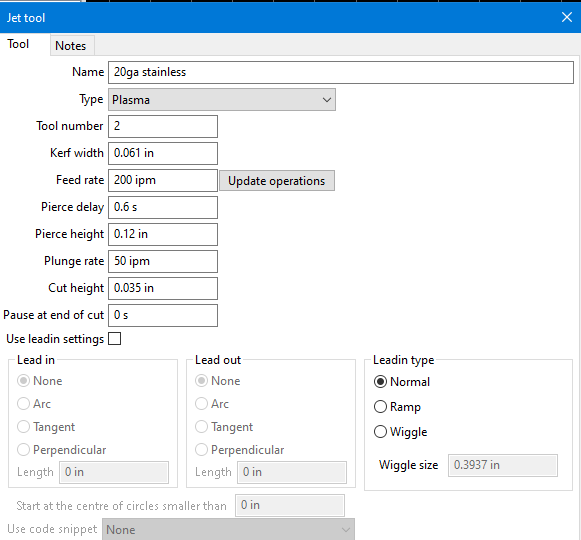

I use the Primeweld Cut60 and luckily have the fine consumables. I typically use the 1.1mm tips because you can run 60A through them, I have the .9mm and the .6mm but I think you can only run 30A and 20A respectively. For 20 gauge though that should be plenty. Good tip on the cut height, I will have to remember to make that adjustment in Fusion. Probably need to adjust the pierce height too. I’ll pull the peel off too, I can always hit it with a fine belt sand if I need to put a brush finish back on. As usual, thanks guys!

Now keep in mind, the 0.02 cut height is not arbitrary: that is the recommended cut height in the Hypertherm cut charts for the fine cut consumables with stainless.

I would try what is in the Primeweld cut chart. Don’t know what that is but if it is higher, be prepared to lower it.

Yes, agreed that the pierce height would reduce accordingly (2.5 x cut height).