I was getting decent but not perfect cuts with my RazorWeld 45 on 5/16th’s mild steel. I was getting a lot of angle of the cut and although it was getting through, it was getting through just barely to the point the dross was holding the piece in place.

So, thinking I needed a little more air, I checked my water separator (RapidAir 3/4"). Disassembled it. It had a lot of water in it, but the filter looked pretty clean. But, I cleaned it all up and put it back together.

I also noticed the tip on my torch was not set all the way, so I took it out of the holder, took it apart, checked it, and put it back together correctly. That caused me to have to redo the THC setup, which I guess makes sense becuase I’d changed the Z height of the torch.

However, when I tried to cut my next part on 5/16th. My pierce did not work for about 1", and then there is a very pronounced V and as far as I could tell I was not getting all the way through. The second feature didn’t go through at all and I had to abort the part. So, now I’m not sure what’s going on. Settings are the same … but I’m new and they could be wrong and I was just lucky before. This is by far the most complex part I’ve cut. I kind of saved it for last. So the fact that it’s giving me trouble is not good as it’s a good size chunk of 5/16ths and I’d had to have to junk it.

inner box front door.nc (3.8 KB)

Is that set a consumables wore out?

I looked at the G-Code file and you’re doing a one second Pierce delay and 20 inches per minute, seems reasonable if not maybe a tad slow for 45 amps.

Pierce height is .15 and cut height is .06

I would inspect the consumables really thoroughly check the electrode.

The pit in the middle of the electrode shouldn’t be any more than .04 deep

1 Like

Okay, will do. Time to order more consumables. Thanks for the response.

Edit: Langmuir is out of stock.

Talk to @mechanic416 he will hook you up

1 Like

Thank you, very much (had to be 10 characters)

2 Likes

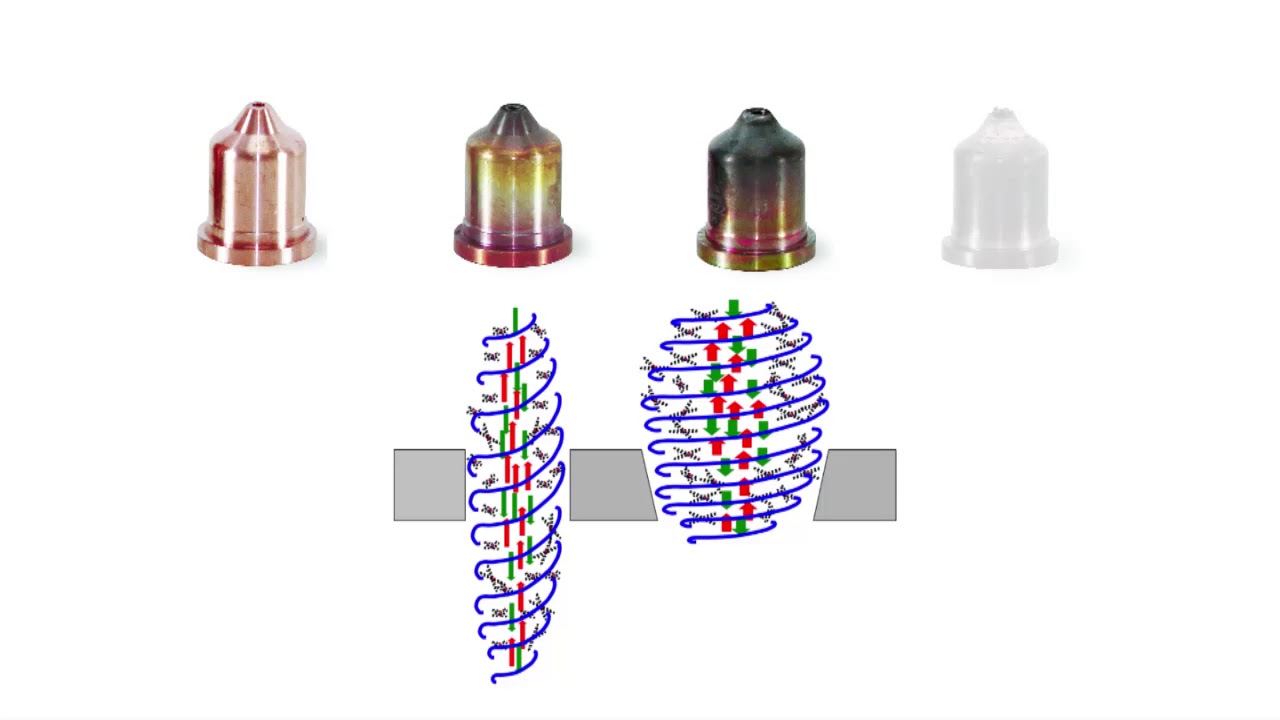

Okay, educate me on consumables. how do these look? software says I have a little over an hour of run time. I Threw the cup that came with the RazorWeld on and it actually cut worse.

That nozzle is “consumed”

Electrode guide

Nozzle guide

Check out these two vodeos

2 Likes

Awesome, that was very helpful. Definitely having to go slower and the kerf is getting much wider. I guess I’m until part arrive. And then I’ll have to figure out if I can salvage the piece I have. I would love to see that on discord/twitch. I’m cutting out the front panel of a smoker fire box and cutting the door and some vents out of it. I need both the inside and outside of the door cut. I’d love to see you go over how to set up so you do the cuts center and inline. Also, when I get back to operational, I’m going to have to figure out how to re-locate my plate relative to the torch head.

I wanted to come back and say thanks for the help. While I’m waiting on the good stuff, I got some of the questionable stuff from Amazon (along with the toilet paper water extractor) and boy - does it cut like a beauty. Now I understand about consumables. I didn’t even notice the degradation the first time. But I will from now on.

1 Like

Definitely come back and post some of your completed projects.

This is the second reference to using a roll of toilet paper, that I have seen. Is that really what people use instead of the $16 filter they sell?

I’m assuming it just looks like a roll of toilet paper. But maybe …

If you really use toilet paper your going to have a hole lot of trouble. Take a roll of toilet paper get it wet and see what happens when you run 120 psi through it.

I have seen were people have tried it and plugged up there air lines, plasma cutter, air tools, paint guns, etc.

3 Likes

Thanks George. I agree. I do not have the motor guard filter for the fact that I can’t square the numbers. I may not use my table anymore than every few weeks. I would not be able to keep up with the maintenance of the filter replacement.

My Harbor Freight dryer arrives today. I have been doing pretty well without any significant drying efforts. And, consumables have been lasting more than 900 piercings but I want to clean up some of the dross.

I think @TinWhisperer hit the nail on the head with this thread. Those consumables have been tortured.

1 Like

Ya, with less than an hours total run time, and way less than 900 piercings, and a water separator inline. So, I’m curious what caused it.

I am really quite a novice at all this but you said:

Are you saying the torch in the holder or the tip within the torch itself? I actually put my torch together wrong (Hypertherm) and it was still try to fire but BADLY. Discovered what I had done and vowed never to admit it to anyone (so mums the word). If there is any mishap with the alignment of the electrode and the shield, that will escalate all sorts of havoc. I have various water trap filters and have never noticed any water or vapor. The fact that you had some water, that could mean something.

And you mentioned the air supply: many people consider that if there is not enough air your consumables will be toast pretty quickly. It has been mentioned on other threads that perhaps air pressure greater than what the cutter’s recommendation may be safer to help for better cuts and extend the life of the consumables. It might void your cutter’s warrantee so you need others advice on that. The Hypertherm regulates the air for me so I have 120 psi right to the back of the cutter.

Just throwing some thoughts out there.

yes, when I looked at it, the outer housing was not properly threaded on. I have no idea if it started that way or happened during various collisions that happened the first copule of days, but it definitely wasn’t right. Much happier now.

I have lots of air available. I’m going to put the toilet paper filter at the plasma cutter’s air drop and I’ll put a pressure gauge there too so I can keep track.

You will be a lot happier if you add a desiccant dryer with the motor guard or any other filter.

The motor guard will not remove enough if any suspended moisture.

1 Like

For real you have seen people put actual toilet paper in a filter?

Yes I have. And have had them in for repair for no air flow. I have had plasma cutters sent it full of sand, water, ice, rust, etc.

2 Likes