Anyone know if there is a .step or .f3d file for the low profile vise…

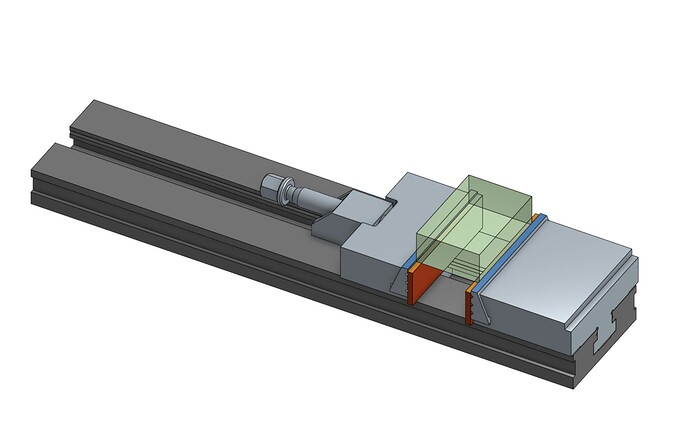

Here is one that is close to Langmuir’s Low profile

Thanks. That is pretty close. Going to make a usable Vise for modeling with movable Jaws.

I posted one on this thread a while ago.

https://forum.langmuirsystems.com/t/mr-1-fusion-360-machine-builder/26339

If anyone is interested, here is a working model of the SMW Langmuir vise assembly with self aligning jaws and fully adjustable stock using the “Change Parameters” setting.

Langmuir_MR-1_20x6 Master v4.f3d (1.3 MB)

If you’re the one that made this, thank you for putting in the effort and sharing!

Edit: I notice this model is fairly far off dimensionally from the actual thing.

Edit2: I modeled up a more accurate Langmuir Low Profile vise in Onshape, with proper dimensions and configurations. Should be reasonably accurate (± .25mm or better), but I’d still recommend leaving a ~0.5 mm clearance if you use this as a fixture model.

Hey thats great. Yeah i made it but only the moving parts and added the change parameters so when you change your stock size it automatically changes with the setting. Thanks for improving it.

has any one made soft jaws for this vice? I was expecting it to be like a kurt but definitely not.

Also does anyone else have issues with the jaws lifting as they tighten?

Yes, the movable jaw lifts a bit. With that low profile of a design, it would be difficult to integrate an anti-lift mechanism and balance cost and ease of use. A couple good whacks with a dead blow seats stock pretty good.

yeah just leaves small marks on my finish machined surfaces. Havent broken out my saunders vice but hopefully that will be a little better.

Soft jaws for this is on my list of things to build for the same reason. I like the grab on the material, but the marks on finished parts is oess than desirable.

For the jaw lift, have you broken the jaw bolts loose to let them have the “pull down” ability? I haven’t had any jaw lift that hasn’t been countered by the jaws moving. It’s basically a Gerardi style vise but much more cost affective.

I havent screwed with the vice much im gonna have a closer look at it.

I don’t think they give any instruction with the vise as far as how they work. If you already know this then disregard, but it may be helpful for someone.

There will be two bolts that go through the movable jaw and fixed jaw of the vise into the hard jaws.

Out of the box these will most likely be tightened down. After tramming the vise in across the hard jaw face of the fixed jaw you can loosen the 2 bolts on either jaw by around 1-2 turns, depending on the desired jaw travel, and allow the jaws to release and raise up.

As you tighten the vise the jaws will seat against the tapered face of the hard jaws and vise jaws to draw the hard jaws downward and load the workpiece against the vise body or parallels under the workpiece.

Any time you install the vise and get ready to tram it in, chuck up on a 1-2-3 block or another squared off block until the jaws are fully seated. Then either indicate the block straight, or tighten the floating hard jaw bolts on the fixed vise jaw and unchuck the block and use the hard jaw face to indicate the vise in parallel to the X or Y axis.

That’s probably a lot more word salad than is needed to explain the setup of the vise. There are some good videos about the cleaning and operation of Gerardi vises that show them in action. Once you get the feel of them you won’t want to used a fixed jaw vise again ![]()

Just pop the hard jaws off and wipe everything down every so often and you’ll be golden. With the vise unchucked and the jaws lifted up by the springs underneath you can take an air gun and blast any chips out from under them between parts or ops and prevent having to take the jaws off for a long time.

Thanks for this… I was like why the F is anyone taking the time to cut tapered vice jaws, I figured there was some sort of purpose but not as good as this LOL.

You’re a friggin’ genius, it worked perfectly! I had never used that type of vice before and just assumed they were fixed and supposed to be tight. They should have included instructions. Thak you very much!