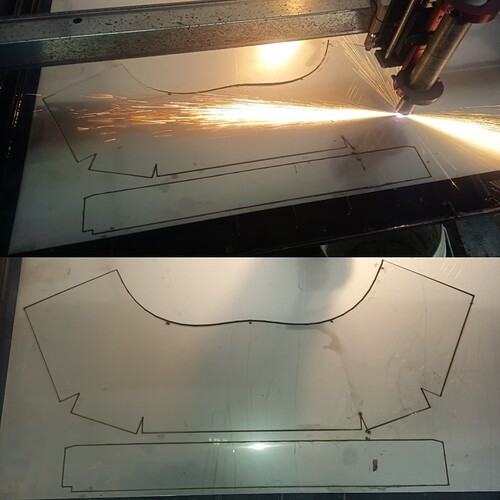

Here are a few things I do when cutting stainless.

-Peel the plastic film from material.

-cut height .02" pierce height .08"

-short as possible pierce delay

-cut as fast as possible while maintaining geometry

(start with 35 amps at 200ipm,I have a powermax 85 so I am taking a guess here)

-Pour water on sheet during cut if geometry is complex and could build up heat.

-(with the Powermax I use Finecuts unshielded)

This is my rough approach when cutting stainless with my power max you will need tweak these for the Razerweld.