Hi There,

I spent several days adjusting the tram of the head, both in X and in Y. I used a 1.2.3 block, and measured against multiple sides to make sure that the block was really parallel. It was nothing like what the online calculator indicated. In fact, it needed shims on the bottom of the spindle housing, not the top!

I put a magnetic base on the dial indicator, and clamped it to the big block at the bottom of the spindle carriage. I adjusted the dial indicator to run against a 123 block that I bolted about in the center of the plate. Anyway, along the X axis, I get 0.000 of movement on the dial indicator when going up the 3" side of the 123 block, which is great!

Along the y axis, I got it down to about +/- .001 along the side of the block.

I thought, ok, now that that perpendicular to the bed, I can use my new EDGE tram gauge and it should read 0 if I rotate the spindle by hand.

So I chucked it up, and the gauges move a lot, like +/- 0 .010 as I rotate the spindle 180 degrees. If I set one gauge to read 0, with it facing the front of the machine, and then I rotate the spindle 180 degrees, it may read .010".

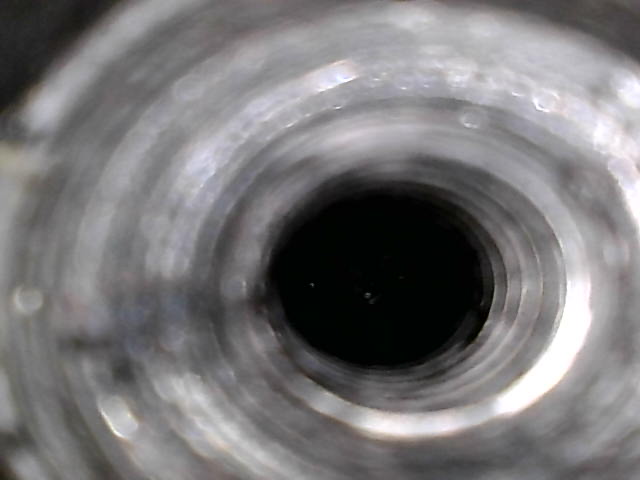

I could not figure where the error was coming from. I put a dial indicator on the outside of the spindle and rotated it by hand, and the indicator only moves +/- .0005 or so, so its pretty good.

I put a 1/2" collet in, and put in my ‘only’ 1/2" endmill, made sure it was deep enough, and then indicated on it. It wobbled .004" up by the spindle nut, which I think is way too much.

I then put in a 3/8" collet and a 3/8" endmill, and got basically the same thing.

Suggestions? Could I have a poorly machined spindle?

Tracy